高等学校化学学报 ›› 2024, Vol. 45 ›› Issue (9): 20240174.doi: 10.7503/cjcu20240174

宋佳欣1,2, 范晓强2( ), 刘百军1(

), 刘百军1( ), 赵震1,2(

), 赵震1,2( )

)

收稿日期:2024-04-10

出版日期:2024-09-10

发布日期:2024-07-30

通讯作者:

范晓强,刘百军,赵震

E-mail:fanxiaoqiang1986@126.com;bjliu@cup.edu.cn;zhaozhen1586@163.com

作者简介:范晓强, 女, 博士, 教授, 主要从事低碳烷烃催化转化方面的研究. E⁃mail: fanxiaoqiang1986@126.com基金资助:

SONG Jiaxin1,2, FAN Xiaoqiang2( ), LIU Baijun1(

), LIU Baijun1( ), ZHAO Zhen1,2(

), ZHAO Zhen1,2( )

)

Received:2024-04-10

Online:2024-09-10

Published:2024-07-30

Contact:

FAN Xiaoqiang, LIU Baijun, ZHAO Zhen

E-mail:fanxiaoqiang1986@126.com;bjliu@cup.edu.cn;zhaozhen1586@163.com

Supported by:摘要:

甲烷氧化偶联(OCM)作为生产C2(C2H6和C2H4)的直接途径受到了广泛关注. 在传统催化剂中, Mn/Na2WO4/SiO2(Na-W-Mn/SiO2)类催化剂具有甲烷转化率高、 C2选择性高且在高温下也能保持相对高的稳定性等优点. 本文利用硅钨酸作为前驱体, 制备了一系列不同W载量的Na-nW-Mn/SiO2催化剂, 并进行了X射线粉末衍射、 透射电子显微镜、 氢气程序升温还原、 氧气程序升温脱附和X射线光电子能谱表征以及甲烷氧化偶联活性的评价. 研究发现, 所有催化剂上的Na2WO4、 Mn2O3和α-方英石晶相之间均存在较强的相互作用, 并通过协同催化作用来提高催化剂的OCM性能. 随着W载量的持续增加, 以硅钨酸作为前驱体制备的催化剂表面的W物种一直保持以四面体WO4的形式存在, 而构效关系分析揭示了四面体WO4是此系列催化剂上OCM反应的活性中心. 具有高含量四面体WO4的Na-10.0%W-Mn/SiO2催化剂有较低的W6+→W4+还原温度和较高的表面晶格氧占比, 这可能是其获得最佳甲烷转化率和C2产率的主要原因. 当温度为775 ℃时, Na-10.0%W-Mn/SiO2催化剂上CH4的转化率为44.2%, C2的产率为24.1%, 其中乙烯的产率为18.7%.

中图分类号:

TrendMD:

宋佳欣, 范晓强, 刘百军, 赵震. Na-W-Mn/SiO2催化剂上不同含量WO4活性位点在甲烷氧化偶联中的催化行为. 高等学校化学学报, 2024, 45(9): 20240174.

SONG Jiaxin, FAN Xiaoqiang, LIU Baijun, ZHAO Zhen. Catalytic Behavior of Different Amounts of WO4 Active Sites on Na-W-Mn/SiO2 Catalysts for Oxidative Coupling of Methane. Chem. J. Chinese Universities, 2024, 45(9): 20240174.

| Catalyst | SBETa /(m2·g-1) | Vtb /(cm3·g-1) | H2 consumption/(mmol·g-1) | O2 desorption/(mmol·g-1) |

|---|---|---|---|---|

| SiO2 | 200 | — | — | — |

| Na⁃1.0%W⁃Mn/SiO2 | 0.7 | 0.001 | 0.43 | 0.07 |

| Na⁃2.5%W⁃Mn/SiO2 | 1.1 | 0.002 | 1.06 | 0.12 |

| Na⁃5.0%W⁃Mn/SiO2 | 0.7 | 0.001 | 1.69 | 0.13 |

| Na⁃10.0%W⁃Mn/SiO2 | 0.8 | 0.002 | 3.00 | 0.16 |

| Na⁃15.0%W⁃Mn/SiO2 | 1.4 | 0.002 | 3.70 | 0.14 |

Table 1 Textural properties and the capacity of H2 consumption and O2 desorption of Na-nW-Mn/SiO2 catalysts

| Catalyst | SBETa /(m2·g-1) | Vtb /(cm3·g-1) | H2 consumption/(mmol·g-1) | O2 desorption/(mmol·g-1) |

|---|---|---|---|---|

| SiO2 | 200 | — | — | — |

| Na⁃1.0%W⁃Mn/SiO2 | 0.7 | 0.001 | 0.43 | 0.07 |

| Na⁃2.5%W⁃Mn/SiO2 | 1.1 | 0.002 | 1.06 | 0.12 |

| Na⁃5.0%W⁃Mn/SiO2 | 0.7 | 0.001 | 1.69 | 0.13 |

| Na⁃10.0%W⁃Mn/SiO2 | 0.8 | 0.002 | 3.00 | 0.16 |

| Na⁃15.0%W⁃Mn/SiO2 | 1.4 | 0.002 | 3.70 | 0.14 |

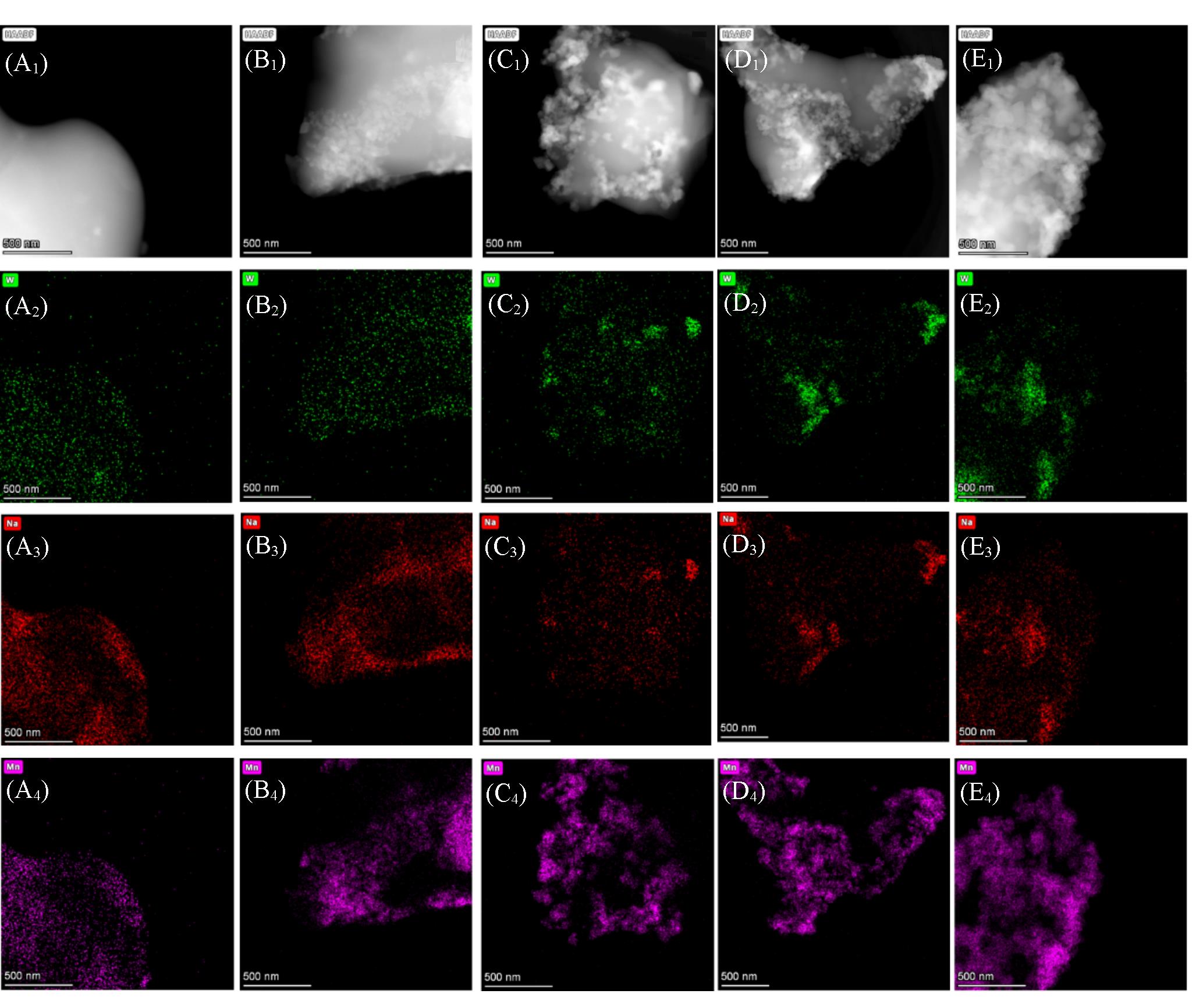

Fig.2 TEM(A1—E1) and EDS mapping images(A2—E2, A3—E3, A4—E4) of Na⁃nW⁃Mn/SiO2 catalysts(A1—A4) Na⁃1.0%W⁃Mn/SiO2; (B1—B4) Na⁃2.5%W⁃Mn/SiO2; (C1—C4) Na⁃5.0%W⁃Mn/SiO2; (D1—D4) Na⁃10.0%W⁃Mn/SiO2; (E1—E4) Na⁃15.0%W⁃Mn/SiO2.

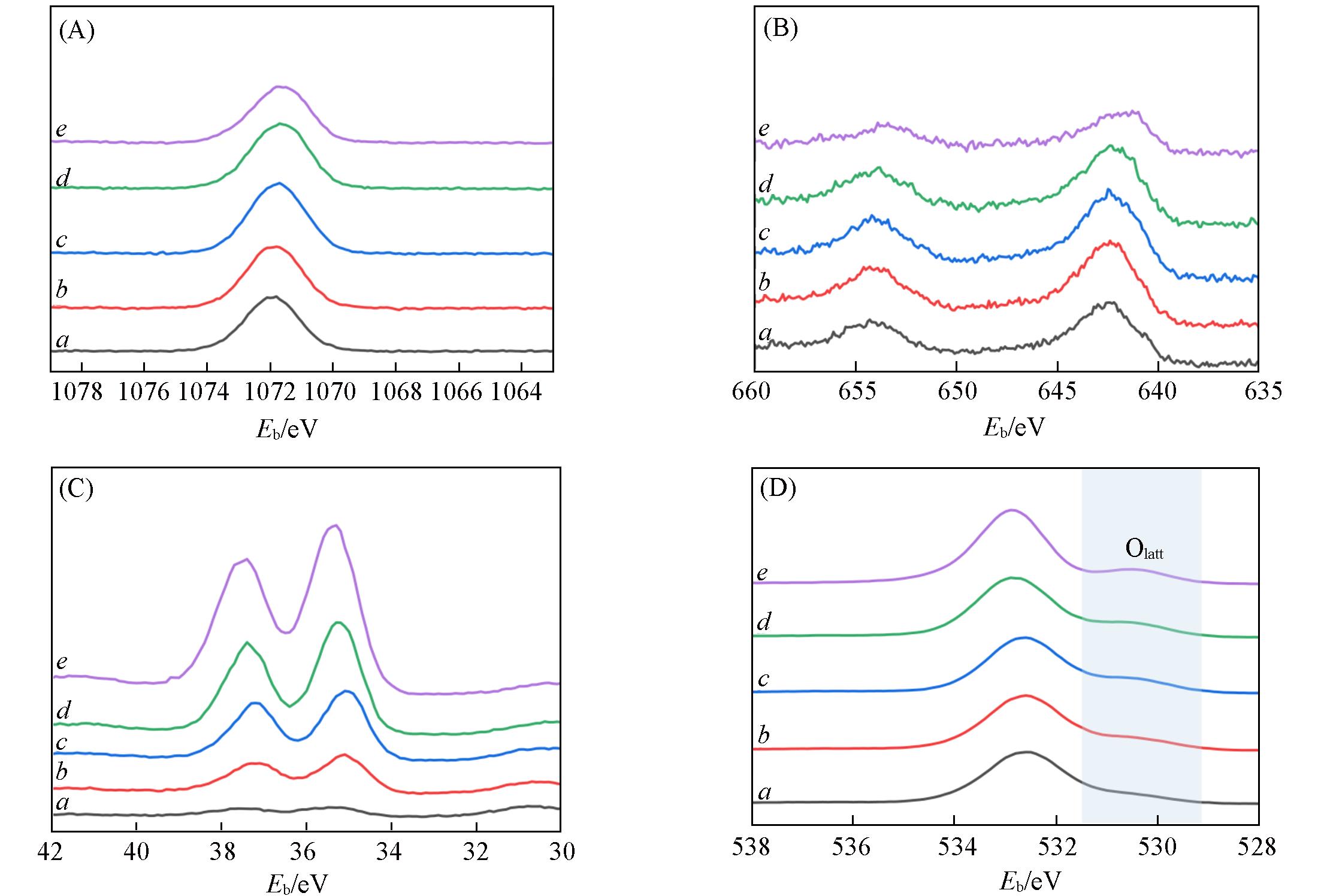

Fig.6 Na1s (A), Mn2p (B), W4f (C) and O1s (D) XPS spectra of Na⁃nW⁃Mn/SiO2 catalystsa. Na⁃1.0%W⁃Mn/SiO2; b. Na⁃2.5%W⁃Mn/SiO2; c. Na⁃5.0%W⁃Mn/SiO2; d. Na⁃10.0%W⁃Mn/SiO2; e. Na⁃15.0%W⁃Mn/SiO2.

| Catalyst | Eb/eV | Composition(%, molar faction) | ||||

|---|---|---|---|---|---|---|

| Na1s | W4f | Mn2p | Na1s | W4f | Mn2p | |

| Na⁃1.0%W⁃Mn/SiO2 | 1071.4 | 34.9 | 641.9 | 7.1 | 0.1 | 1.6 |

| Na⁃2.5%W⁃Mn/SiO2 | 1071.3 | 34.6 | 641.8 | 7.9 | 0.5 | 1.9 |

| Na⁃5.0%W⁃Mn/SiO2 | 1071.2 | 34.6 | 641.7 | 8.5 | 0.9 | 2.0 |

| Na⁃10.0%W⁃Mn/SiO2 | 1071.1 | 34.6 | 641.5 | 7.5 | 1.3 | 1.8 |

| Na⁃15.0%W⁃Mn/SiO2 | 1071.1 | 34.8 | 641.2 | 6.0 | 1.9 | 1.0 |

Table 2 Binding energies(Eb) and near-surface compositions detected from XPS analysis of Na-nW-Mn/SiO2 catalysts

| Catalyst | Eb/eV | Composition(%, molar faction) | ||||

|---|---|---|---|---|---|---|

| Na1s | W4f | Mn2p | Na1s | W4f | Mn2p | |

| Na⁃1.0%W⁃Mn/SiO2 | 1071.4 | 34.9 | 641.9 | 7.1 | 0.1 | 1.6 |

| Na⁃2.5%W⁃Mn/SiO2 | 1071.3 | 34.6 | 641.8 | 7.9 | 0.5 | 1.9 |

| Na⁃5.0%W⁃Mn/SiO2 | 1071.2 | 34.6 | 641.7 | 8.5 | 0.9 | 2.0 |

| Na⁃10.0%W⁃Mn/SiO2 | 1071.1 | 34.6 | 641.5 | 7.5 | 1.3 | 1.8 |

| Na⁃15.0%W⁃Mn/SiO2 | 1071.1 | 34.8 | 641.2 | 6.0 | 1.9 | 1.0 |

| Catalyst | Reaction condition | CH4 conversion(%) | C2 selectivity(%) | C2 yield(%) | Ref. | |

|---|---|---|---|---|---|---|

| 1.5%Mn⁃4%Na2WO4/Zeo⁃A | 750 ℃, CH4/O2/N2/Ar volume ratio: 4∶1∶1∶4 | 25.0% | 64.0% | 16.0% | [ | |

| Mn x O y ⁃Na2WO4/mes⁃TiO2⁃rutile | 750 ℃, CH4/O2/N2 volume ratio: 4∶1∶4 | 6.8% | 42.8% | 2.9% | [ | |

| Ir⁃Mn x O y ⁃Na2WO4/MCF⁃17 | 750 ℃, CH4/O2/N2 volume ratio: 4∶1∶4 | 14.4% | 46.7% | 6.7% | [ | |

| 2%P/0.4%S⁃Na⁃W⁃Mn⁃Zr/SiO2 | 750 ℃, CH4/O2 volume ratio: 3∶1 | 34.1% | 48.4% | 16.5% | [ | |

| Na2WO4⁃Mn x O y /COK⁃12 | 775 ℃, CH4/N2/O2 volume ratio: 40∶40∶10 | 24.0% | 60.5% | 14.5% | [ | |

| NWM/Mg(5)Ti(5)Si(90) | 775 ℃, CH4/O2 volume ratio: 3∶1 | 30.9% | 62.3% | 19.3% | [ | |

| 1.9%Mn⁃5%Na2WO4⁃5%Ce/TiO2 | 775 ℃, CH4/O2/N2 volume ratio: 2∶1∶1 | 49.4% | 52.8% | 26.1% | [ | |

M⁃Na⁃Mn/SiO2 (M=W, Mo, Nb, V, Cr) | 775 ℃, CH4/O2/N2 volume ratio: 2∶1∶2 | 46.1% | 39.6% | 18.3% | [ | |

| 0.8%Na⁃3.1%W⁃2%Mn/SiO2 | 800 ℃, CH4/O2 volume ratio: 3∶1 | 29.7% | 63.2% | 18.8% | [ | |

| La⁃5%Na2WO4/2%Mn/SiO2 | 800 ℃, CH4/O2 volume ratio: 2∶1 | 41.0% | 42.8% | 17.5% | [ | |

| Na2WO4⁃Mn/SiO2 | 800 ℃, CH4/O2 volume ratio: 3.2∶1 | 29.5% | 66.4% | 19.6% | [ | |

| Mn⁃Na2WO4/n⁃SiO2 | 800 ℃, CH4/O2 volume ratio: 4∶1 | 25.5% | 73.3% | 18.5% | [ | |

| Na⁃10.0%W⁃Mn/SiO2 | 750 ℃, CH4/O2 volume ratio: 4∶1 | 32.9% | 58.3% | 19.2% | This work | |

| 775 ℃, CH4/O2 volume ratio: 2∶1 | 44.2% | 54.5% | 24.1% | |||

| 800 ℃, CH4/O2 volume ratio: 2∶1 | 45.2% | 53.3% | 24.1% | |||

Table 3 OCM performance of some Na-W-Mn/SiO2 catalysts

| Catalyst | Reaction condition | CH4 conversion(%) | C2 selectivity(%) | C2 yield(%) | Ref. | |

|---|---|---|---|---|---|---|

| 1.5%Mn⁃4%Na2WO4/Zeo⁃A | 750 ℃, CH4/O2/N2/Ar volume ratio: 4∶1∶1∶4 | 25.0% | 64.0% | 16.0% | [ | |

| Mn x O y ⁃Na2WO4/mes⁃TiO2⁃rutile | 750 ℃, CH4/O2/N2 volume ratio: 4∶1∶4 | 6.8% | 42.8% | 2.9% | [ | |

| Ir⁃Mn x O y ⁃Na2WO4/MCF⁃17 | 750 ℃, CH4/O2/N2 volume ratio: 4∶1∶4 | 14.4% | 46.7% | 6.7% | [ | |

| 2%P/0.4%S⁃Na⁃W⁃Mn⁃Zr/SiO2 | 750 ℃, CH4/O2 volume ratio: 3∶1 | 34.1% | 48.4% | 16.5% | [ | |

| Na2WO4⁃Mn x O y /COK⁃12 | 775 ℃, CH4/N2/O2 volume ratio: 40∶40∶10 | 24.0% | 60.5% | 14.5% | [ | |

| NWM/Mg(5)Ti(5)Si(90) | 775 ℃, CH4/O2 volume ratio: 3∶1 | 30.9% | 62.3% | 19.3% | [ | |

| 1.9%Mn⁃5%Na2WO4⁃5%Ce/TiO2 | 775 ℃, CH4/O2/N2 volume ratio: 2∶1∶1 | 49.4% | 52.8% | 26.1% | [ | |

M⁃Na⁃Mn/SiO2 (M=W, Mo, Nb, V, Cr) | 775 ℃, CH4/O2/N2 volume ratio: 2∶1∶2 | 46.1% | 39.6% | 18.3% | [ | |

| 0.8%Na⁃3.1%W⁃2%Mn/SiO2 | 800 ℃, CH4/O2 volume ratio: 3∶1 | 29.7% | 63.2% | 18.8% | [ | |

| La⁃5%Na2WO4/2%Mn/SiO2 | 800 ℃, CH4/O2 volume ratio: 2∶1 | 41.0% | 42.8% | 17.5% | [ | |

| Na2WO4⁃Mn/SiO2 | 800 ℃, CH4/O2 volume ratio: 3.2∶1 | 29.5% | 66.4% | 19.6% | [ | |

| Mn⁃Na2WO4/n⁃SiO2 | 800 ℃, CH4/O2 volume ratio: 4∶1 | 25.5% | 73.3% | 18.5% | [ | |

| Na⁃10.0%W⁃Mn/SiO2 | 750 ℃, CH4/O2 volume ratio: 4∶1 | 32.9% | 58.3% | 19.2% | This work | |

| 775 ℃, CH4/O2 volume ratio: 2∶1 | 44.2% | 54.5% | 24.1% | |||

| 800 ℃, CH4/O2 volume ratio: 2∶1 | 45.2% | 53.3% | 24.1% | |||

| 1 | Keller G. F., Bhasin M. M., J. Catal., 1982, 73(1), 9—19 |

| 2 | Zou S. H., Li Z. N., Zhou Q. Y., Pan Y., Yuan W. T., He L., Wang S. L., Wen W., Liu J. J., Wang Y., Du Y. H., Yang J. Z., Xiao J. P., Kobayashi H., Fan J., Chinese J. Catal., 2021, 42(7), 1117—1125 |

| 3 | Kiani D., Sourav S., Baltrusaitis J., Wachs I. E., ACS Catal., 2019, 9(7), 5912—5928 |

| 4 | Song J. X., Ren Y., Gao X., Fan X. Q., Liu B. J., Zhao Z., ACS Catal., 2024, 14, 5116—5131 |

| 5 | Zanina A., Kondratenko V. A., Lund Henrik., Li J. S., Chen J., Li Y. M., Jiang G. Y., Kondratenko E. V., J. Catal., 2023, 419, 68—79 |

| 6 | Zhao K., Gao Y. F., Wang X. J., Lis B. M., Liu J. C., Jin B. T., Smith J., Huang C. D., Gao W. P., Wang X. D., Wang X., Zheng A. Q., Huang Z., Hu J. L., Schömacker R., Wachs I. E., Li F. X., Nat. Commun., 2023, 14, 7749 |

| 7 | Cong L. N., Zhao Y. H., Li S. G., Sun Y. H., Chinese J. Catal., 2017, 38(5), 899—907 |

| 8 | Wu T. T., Wei Y. C., Xiong J., Yang Y. T., Wang Z. P., Han D. W., Zhao Z., Liu J., J. Energy Chem., 2024, 91, 331—344 |

| 9 | Fang X. Z., Xia L. H., Peng L., Luo Y., Xu J. W., L. Xu J., Xu X. L., Liu W. M., Zheng R. Y., Wang X., Chinese Chem. Lett., 2019, 30(6), 1141—1146 |

| 10 | Cho J. H., Kwon D., Yang I., An S., Jung J. C., Mol. Catal., 2021, 510, 111677 |

| 11 | Qian K., You R., Guan Y., Wen W., Tian Y. C., Pan Y., Huang W. X., ACS Catal., 2020, 10(24), 15142—15148 |

| 12 | Si J., Sun W., Zhao G., Lu Y., Fuel, 2022, 311(1), 122539 |

| 13 | Aydin Z., Kondratenko V. A., Lund H., Bartling S., Kreyenschulte C. R., Linke D., Kondratenko E. V., ACS Catal., 2020, 10(15), 8751—8764 |

| 14 | Fang X. P., Li S. B., Lin J. Z., Chu Y. L., J. Mol. Catal., 1992, 6(6), 7 |

| 方学平, 李树本, 林景治, 禇衍来. 分子催化, 1992, 6(6), 7 | |

| 15 | Wu J., Li S., J. Phys. Chem., 1995, 99(13), 4566—4568 |

| 16 | Ji S. F., Xiao T. C., Li S. B., Chou L. J., Zhang B., Xu C. Z., Hou R. L., York A. P. E, Green M. L. H., J. Catal., 2003, 220(1), 47—56 |

| 17 | Ji S. F., Xiao T. C., Li S. B., Xu C. Z., Hou R. L., Coleman K. S., Green M. L. H., Appl. Catal. A: Gen., 2002, 225(1/2), 271—284 |

| 18 | Greish A. A., Glukhov L. M., Finashina E. D., Kustov L. M., Sung J. S., Choo K. Y., Kim T. H., Mendeleev Commun., 2009, 19(6), 337—339 |

| 19 | Jiang Z. C., Yu C. J., Fang X. P., Li S. B., Wang H. L., J. Phys. Chem., 1993, 97(49), 12870—12875 |

| 20 | Si J. Q., Zhao G. F., Lan T., Ni J. Y., Sun W. D., Liu Y., Lu Y., ACS Catal., 2023, 13(2), 1033—1044 |

| 21 | Wang P. W., Zhang X., Zhao G. F., Liu Y., Lu Y., Chinese J. Catal., 2018, 39(8), 1395—1402 |

| 22 | Wu J., Zhang H., Qin S., Hu C., Appl. Catal. A: Gen., 2007, 323(3), 126—134 |

| 23 | Ortiz⁃Bravo C. A., Figueroa S. J. A., Portela R., Chagas C. A., Bañares M. A., Toniolo F. S., J. Catal., 2022, 408, 423—435 |

| 24 | Dedov A. G., Nipan G. D., Loktev A. S., Tyunyaev A. A., Ketsko V. A., Parkhomenko K. V., Moiseev I. I., Appl. Catal. A: Gen., 2011, 406(1/2), 1—12 |

| 25 | Matras D., Vamvakeros A., Jacques S. D. M., Grosjean N., Rollins B., Poulston S., Stenning G. B. G., Godini H. R., Drnec J., Cernik R. J., Beale A. M., Faraday Discuss., 2021, 229, 176—196 |

| 26 | Si J. Q., Zhao G. F., Sun W. D., Liu J. C., Guan C. R., Yang Y., Shi X. R., Lu Y., Angew. Chem. Int. Ed., 2022, 61(18), e202117201 |

| 27 | Gu S. S., Kang J., Lee T., Shim J., Choi J. W., Suh D. J., Lee H., Yoo C., Baik H., Choi J., Chem. Eng. J., 2023, 457(1), 141057 |

| 28 | Zhang X., Hu X., Liu S., Chen Y., Jin S., Wang X., Wang J., Xiao K., Wu X., J. Environ. Chem. Eng., 2022, 10(2), 107318 |

| 29 | Chen H., Wang Y., Lv Y. K., RSC Adv., 2016, 6(59), 54032—54040 |

| 30 | Kompio P. G. W. A., Brückner A., Hipler F., Auer G., Löffler E., Grünert W., J. Catal., 2012, 286, 237—247 |

| 31 | Pal R. S., Rana S., Sharma S. K., Khatun R., Khurana D., Khan T. S., Poddar M. K., Sharma R., Bal R., Chem. Eng. J., 2023, 458, 141379 |

| 32 | Qin Y., Wang H., Dong C., Qu Z. P., J. Catal., 2019, 380, 21—31 |

| 33 | Liu J. W., Huo M. F., Zhu Y., J. Nanosci. Nanotechnol., 2017, 17(12), 8818—8826 |

| 34 | Kim I., Lee G., Na H. B., Ha J. M., Jung J. C., Mol. Catal., 2017, 435, 13—23 |

| 35 | Gu S., Oh H. S., Choi J. W., Suh D. J., Jae J., Choi, J., Ha J. M., Appl. Catal. A: Gen., 2018, 562(25), 114—119 |

| 36 | Simon U., Görke O., Berthold A., Arndt S., Schomäcker R., Schubert H., Chem. Eng. J., 2011, 168(3), 1352—1359 |

| 37 | Hayek N. S., Lucas N. S., Damouny C. W., Gazit Oz. M., ACS Appl. Mater. Interfaces, 2017, 9(46), 40404—40411 |

| 38 | Yildiz M., J. Ind. Eng. Chem., 2019, 76, 488—499 |

| 39 | Liua W. C., Ralstona W. T., Melaet G., Somorjai G. A., Appl. Catal. A: Gen., 2017, 545, 17—23 |

| 40 | Zheng W., Cheng D. G., Zhu N., Chen F. Q., Zhan X. L., J. Nat. Gas Chem., 2010, 19, 15—20 |

| 41 | Colmenares M. G., Simon U., Yildiz M., Arndt S., Schomaecker R., Thomas A., Rosowski F., Gurlo A., Goerke O., Catal. Commun., 2016, 85, 75—78 |

| 42 | Yunarti R. T., Gu S., Choi J. W., Jae J., Suh D. J., Ha J. M., ACS Sustainable Chem. Eng., 2017, 5, 3667—3674 |

| 43 | Kim G. J., Ausenbaugh J. T., Hwang H. T., Ind. Eng. Chem. Res., 2021, 60, 3914—3921 |

| 44 | Mahmoodi S., Ehsani M., Ghoreishi S., J. Ind. Eng. Chem., 2010, 16, 923—928 |

| 45 | Ji S. F., Xiao T. C., Li S. B., Chou L. J., Zhang B., Xu C. Z., Hou R. L., York A. P. E., Green M. L. H., J. Catal., 2003, 220, 47—56 |

| 46 | Elkins T. W., Hagelin⁃Weaver H. E., Appl. Catal. A: Gen., 2015, 497, 96—106 |

| [1] | 张慧莲, 杨新杰, 李军, 李泉, 张福娟, 张艳丽, 王红斌, 杨文荣, 庞鹏飞. 基于N掺杂Ti3C2 MXene量子点的荧光探针用于Hg2+和S2-的传感检测[J]. 高等学校化学学报, 2024, 45(5): 20230504. |

| [2] | 申屠江涛, 李宜蔚, 陆彦戎, 李娟琴, 毛业兵, 李象远. 燃烧机理构建的极小化反应网络方法: C2燃料燃烧[J]. 高等学校化学学报, 2024, 45(1): 20230386. |

| [3] | 白旭, 韩超英, 朱华. 范德华复合物Kr-C2H2的势能面和振转光谱的理论研究[J]. 高等学校化学学报, 2019, 40(8): 1649. |

| [4] | 陈耀燕, 赵昕, 王哲, 董杰, 张清华. 制备条件对MXene形貌、 结构与电化学性能的影响[J]. 高等学校化学学报, 2019, 40(6): 1249. |

| [5] | 白燕, 夏文生, 翁维正, 连孟水, 赵明全, 万惠霖. 磷酸盐的添加对甲烷氧化偶联反应镧基催化剂的影响[J]. 高等学校化学学报, 2018, 39(2): 247. |

| [6] | 沈金瑞, 周哲, 周远, 卢翠芬, 杨桂春, 陈祖兴. 主链含双层倍半硅氧烷的C2-对称双脯氨酰胺手性聚合物催化剂的合成及在不对称Aldol反应中的应用[J]. 高等学校化学学报, 2017, 38(11): 1968. |

| [7] | 杨艳玲, 董玲玉, 夏文生, 万惠霖. Ca, Sr共掺杂铈氧化物及其在甲烷氧化偶联反应中的应用[J]. 高等学校化学学报, 2016, 37(12): 2206. |

| [8] | 赵书涛, 闫冰, 李瑞, 郭庆群, 田传进, 连科研, 潘守甫. C2F5I分子C-I键解离的自旋-轨道从头算研究[J]. 高等学校化学学报, 2009, 30(1): 170. |

| [9] | 于广涛, 李飞, 于健康, 黄旭日, 孙家锺 . NC2S+离子的结构和稳定性的理论研究[J]. 高等学校化学学报, 2007, 28(10): 1957. |

| [10] | 谭克, 滕云雷, 阚玉和, 杨双阳. B(C2H5)2q及其衍生物电子光谱性质的密度泛函理论研究[J]. 高等学校化学学报, 2005, 26(7): 1284. |

| [11] | 白洪涛, 黄旭日, 于健康, 李吉来, 孙家锺. C2H与HO2双自由基反应的密度泛函理论研究[J]. 高等学校化学学报, 2005, 26(4): 697. |

| [12] | 黄琼, 王文翰, 华伟明, 乐英红, 高滋. 微孔层状磷酸铝材料的剥离与嵌入研究[J]. 高等学校化学学报, 2004, 25(11): 2065. |

| [13] | 张冬柏, 齐利民, 马季铭, 程虎民. 双亲水嵌段共聚物存在下特殊形貌的BaC2O4晶体合成[J]. 高等学校化学学报, 2004, 25(1): 159. |

| [14] | 魏志钢, 黄旭日, 孙延波, 孙家锺. 乙炔基自由基(C2H·)与二氧化氮(NO2)气体反应势能面的理论研究[J]. 高等学校化学学报, 2003, 24(12): 2224. |

| [15] | 刘桂霞, 丁益宏, 李泽生, 黄旭日, 孙家锺. 乙烯基自由基(C2H3·)与羟基自由基(OH·)反应势能面的理论研究[J]. 高等学校化学学报, 2002, 23(6): 1147. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||