高等学校化学学报 ›› 2021, Vol. 42 ›› Issue (5): 1395.doi: 10.7503/cjcu20200754

收稿日期:2020-10-19

出版日期:2021-05-10

发布日期:2021-02-10

通讯作者:

杨梅,于然波

E-mail:myang@ipe.ac.cn;ranboyu@ustb.edu.cn

基金资助:

ZHANG Zhen1,2, MAO Dan2,3, YANG Mei2( ), YU Ranbo1(

), YU Ranbo1( )

)

Received:2020-10-19

Online:2021-05-10

Published:2021-02-10

Contact:

YANG Mei,YU Ranbo

E-mail:myang@ipe.ac.cn;ranboyu@ustb.edu.cn

Supported by:摘要:

中空多壳层结构(HoMSs)是一种以纳米颗粒为结构单元构筑而成的具有多界面、 多维度的微纳米级宏观组装体, 具有次序排列的多个壳层及相互连通的多个空腔, 被认为是电磁波领域极具应用前景的功能材料. 本文主要从电磁波捕获、 传输及能量转换3个角度详细阐述HoMSs在电磁波领域应用中的独特优势, 浅析了HoMSs壳层数目、 壳层厚度、 壳层间距、 壳层组成等结构参数对电磁波传输与利用的影响规律, 并预测了HoMSs在电磁波领域的发展趋势, 以期为实现电磁波的高效利用提供参考.

中图分类号:

TrendMD:

张振, 毛丹, 杨梅, 于然波. 中空多壳层结构在电磁波领域中的应用. 高等学校化学学报, 2021, 42(5): 1395.

ZHANG Zhen, MAO Dan, YANG Mei, YU Ranbo. Application of Hollow Multi⁃shelled Structures in Electromagnetic Wave Field. Chem. J. Chinese Universities, 2021, 42(5): 1395.

| Electromagnetic wave | Wavelength/nm | Frequency/Hz | Application |

|---|---|---|---|

| Radio waves | >1000 | <3×1011 | Communications, radar |

| Infrared light | 760—1000 | 1012—3.9×1014 | Photothermal therapy, thermal imaging |

| Visible light | 390—760 | 3.9×1014—7.5×1014 | Photocatalysis, solar cell |

| Ultraviolet light | 10—400 | 7.5×1014—5×1016 | Sterilization, photoelectric detection |

| X?Ray, γ ray, etc. | <10 | >5×1016 | Bioimaging, crystal analysis, medical treatment |

Table 1 Classification and application of electromagnetic waves

| Electromagnetic wave | Wavelength/nm | Frequency/Hz | Application |

|---|---|---|---|

| Radio waves | >1000 | <3×1011 | Communications, radar |

| Infrared light | 760—1000 | 1012—3.9×1014 | Photothermal therapy, thermal imaging |

| Visible light | 390—760 | 3.9×1014—7.5×1014 | Photocatalysis, solar cell |

| Ultraviolet light | 10—400 | 7.5×1014—5×1016 | Sterilization, photoelectric detection |

| X?Ray, γ ray, etc. | <10 | >5×1016 | Bioimaging, crystal analysis, medical treatment |

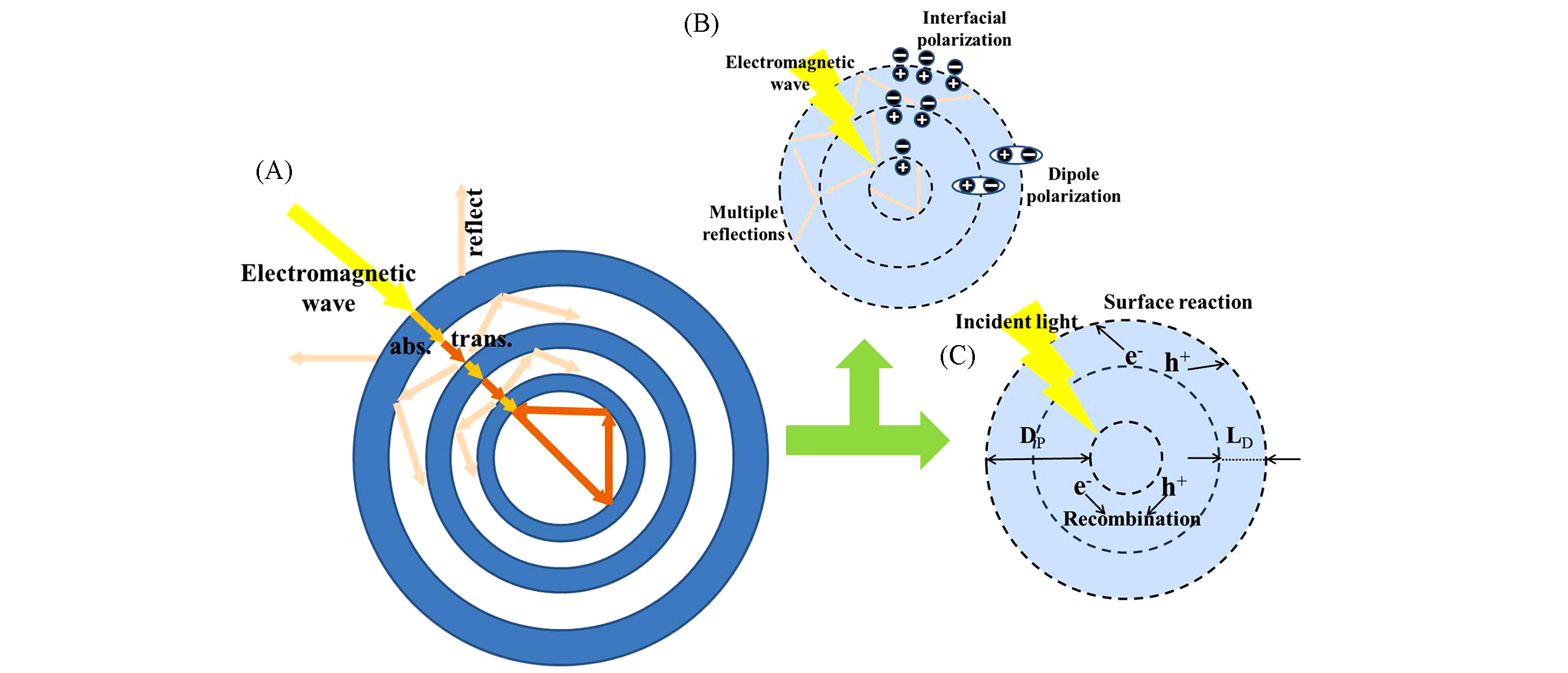

Fig.1 Schematic diagram of electromagnetic wave incidence, propagation and energy conversion in HoMSs(A), diagram of electromagnetic wave energy dissipation(B) and diagram of electromagnetic wave energy storage and conversion(C)

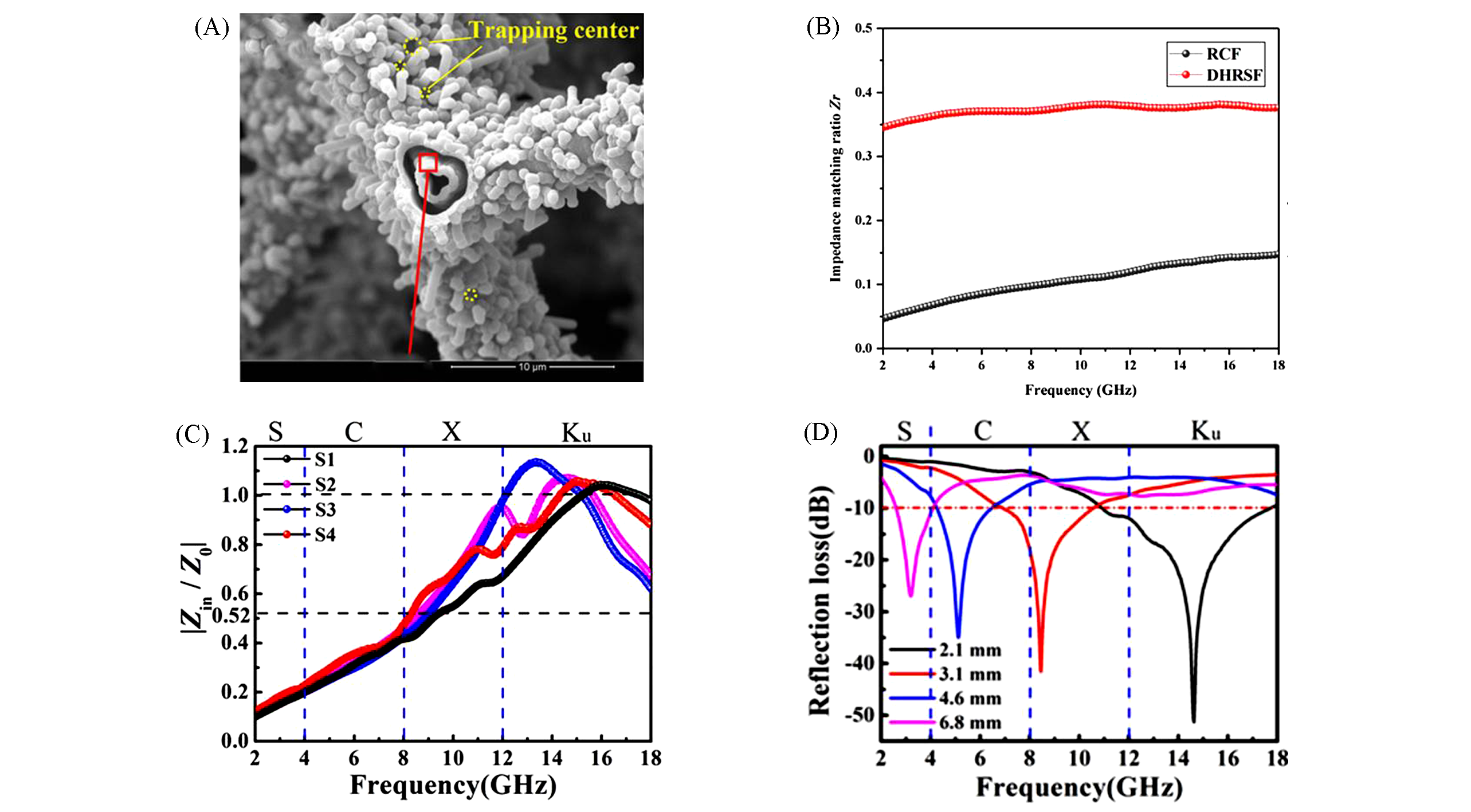

Fig.2 SEM image of DHRSF(A), impedance matching ratio curves of RCF and DHRSF(B)[31], relative input impedance(|Zin/Z0|) curves of single?shell Ni nanoparticles/graphite carbon/nanoporous carbon(S1) and double?shell NiCo nanoparticles with different Ni/Co ratios/graphite carbon/nanoporous carbon(S2: Ni2Co1, S3: Ni1Co1, S4: Ni1Co2)(C) and the electromagnetic wave reflection loss with various thicknesses for Ni1Co2/GC/NPC HoMSs(D)[21](A, B) Copyright 2019, American Chemical Society.(C, D) Copyright 2020, Elsevier B.V.

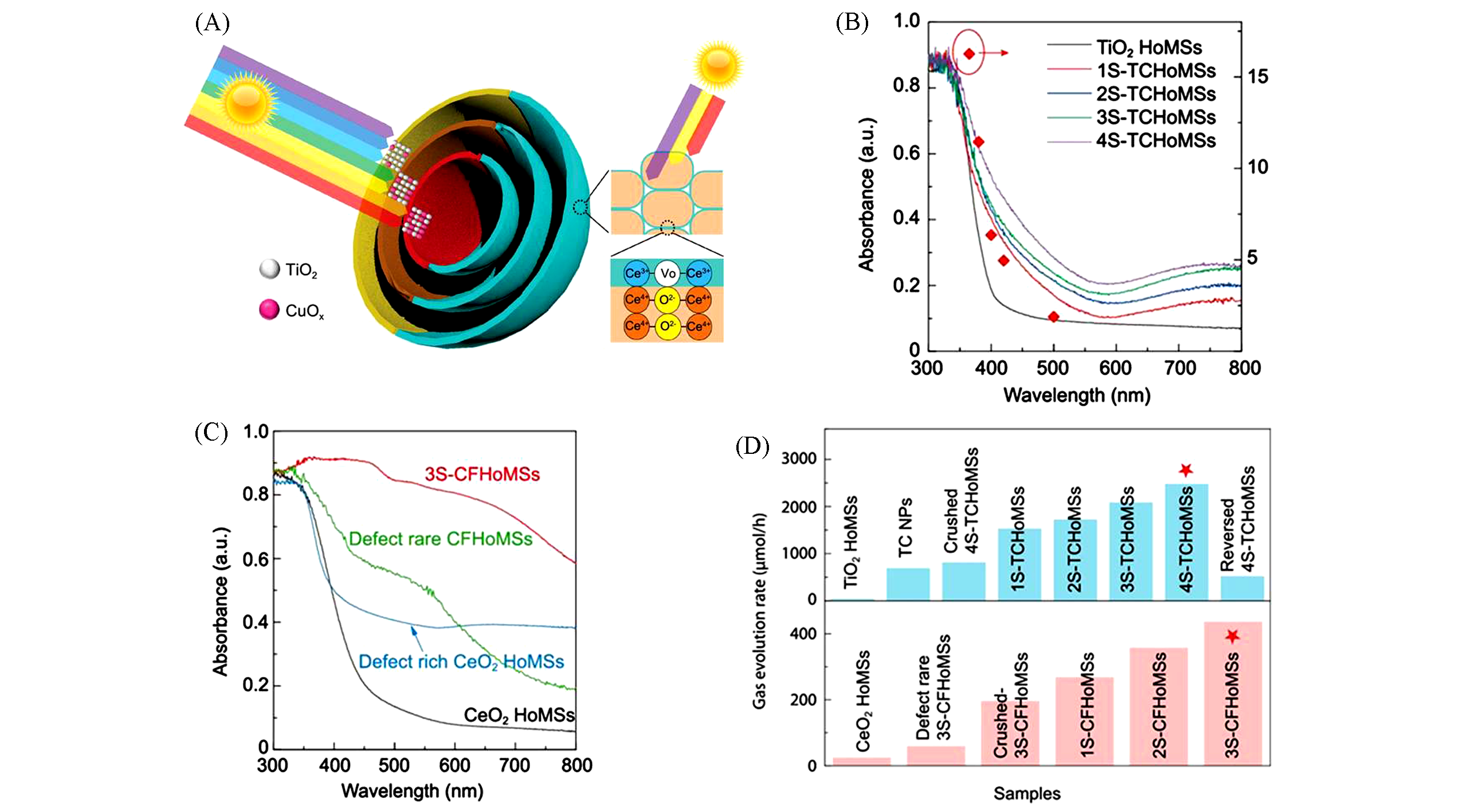

Fig.3 TiO2?CuxO HoMSs(TCHoMSs) and CeO2?CeFeO3 HoMSs(CFHoMSs) sequential absorption three?dimensional model(A), UV?Vis absorption spectra of TCHoMSs with different shell numbers and apparent quantum efficiency(red diamonds) of 4S?TCHoMSs at different wavelengths(B), UV?Vis absorption spectra of 3S?CFHoMSs, CeO2 HoMSs and the corresponding samples with surface defect control(C), hydrogen evolution activity and oxygen evolution activity of TCHoMSs and CFHoMSs related samples(D)[35]Copyright 2020, Oxford University Press.

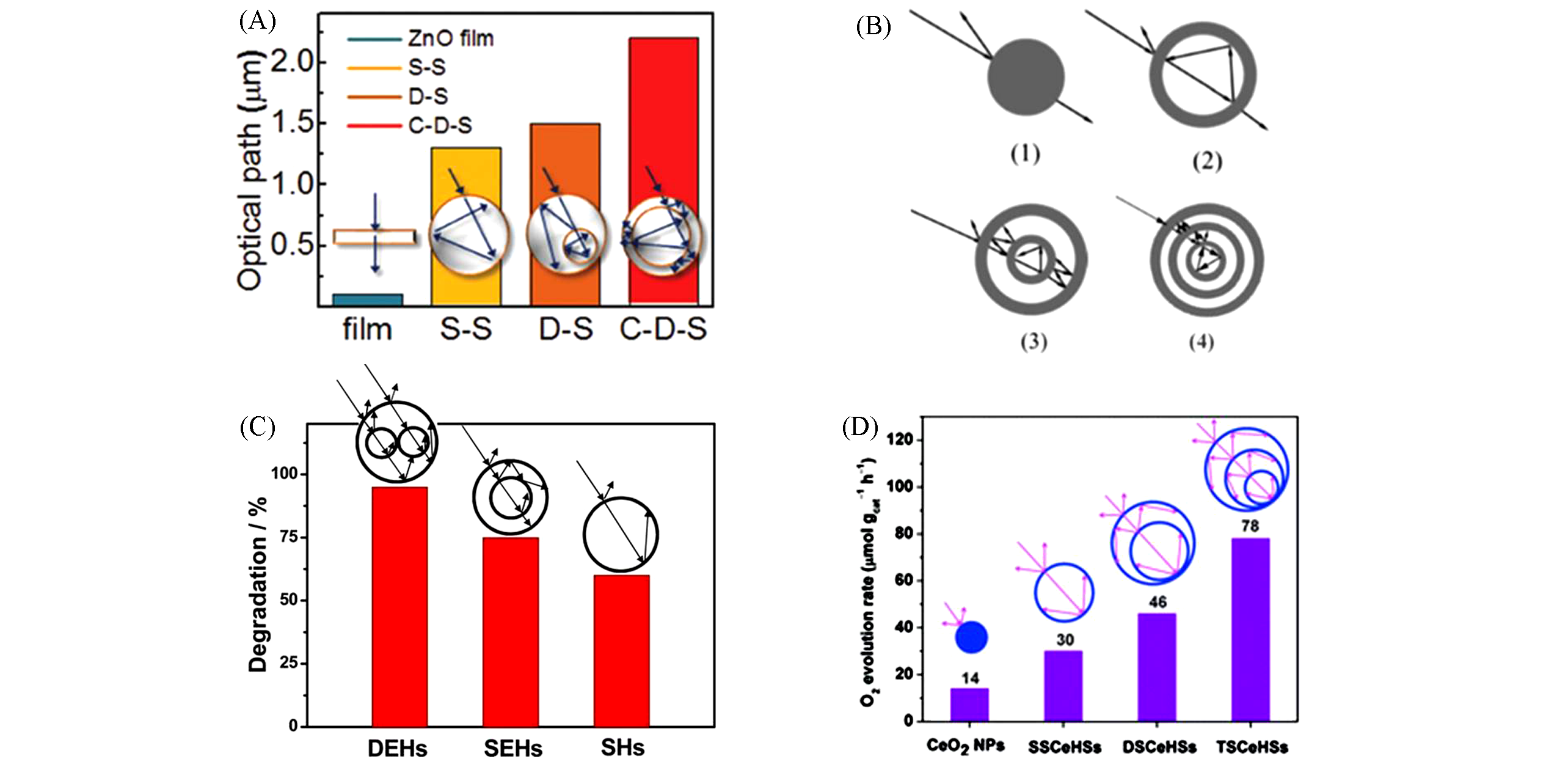

Fig.4 Optical path within different types of ZnO samples and corresponding schematic drawings for the multiple reflection of light within ZnO nanoshell? and film?based devices(A)[19], a microwave pathway illustration of the PEDOT solid structure(1), PEDOT hollow structures(2), double?shelled PEDOT hollow structures(3) and triple?shelled PEDOT hollow structures(4)(B)[37], comparison of photocatalytic activities of ZnO hollow spheres with different morphologies(C)[38], CeO2 HoMSs photocatalytic oxygen evolution reaction efficiency and electromagnetic wave multi?reflections model diagram(D)[40](A) Copyright 2018, Wiley?VCH.(B) Copyright 2014, Royal Society of Chemistry. (C) DEHs: double?yolk egg structures; SEHs: single?yolk egg structures; SHs: single?shelled hollow spheres. The insets show a schematic illustration of the light multi?re?ections within all three structures. Copyright 2012, Wiley?VCH. (D) Copyright 2014, Royal Society of Chemistry.

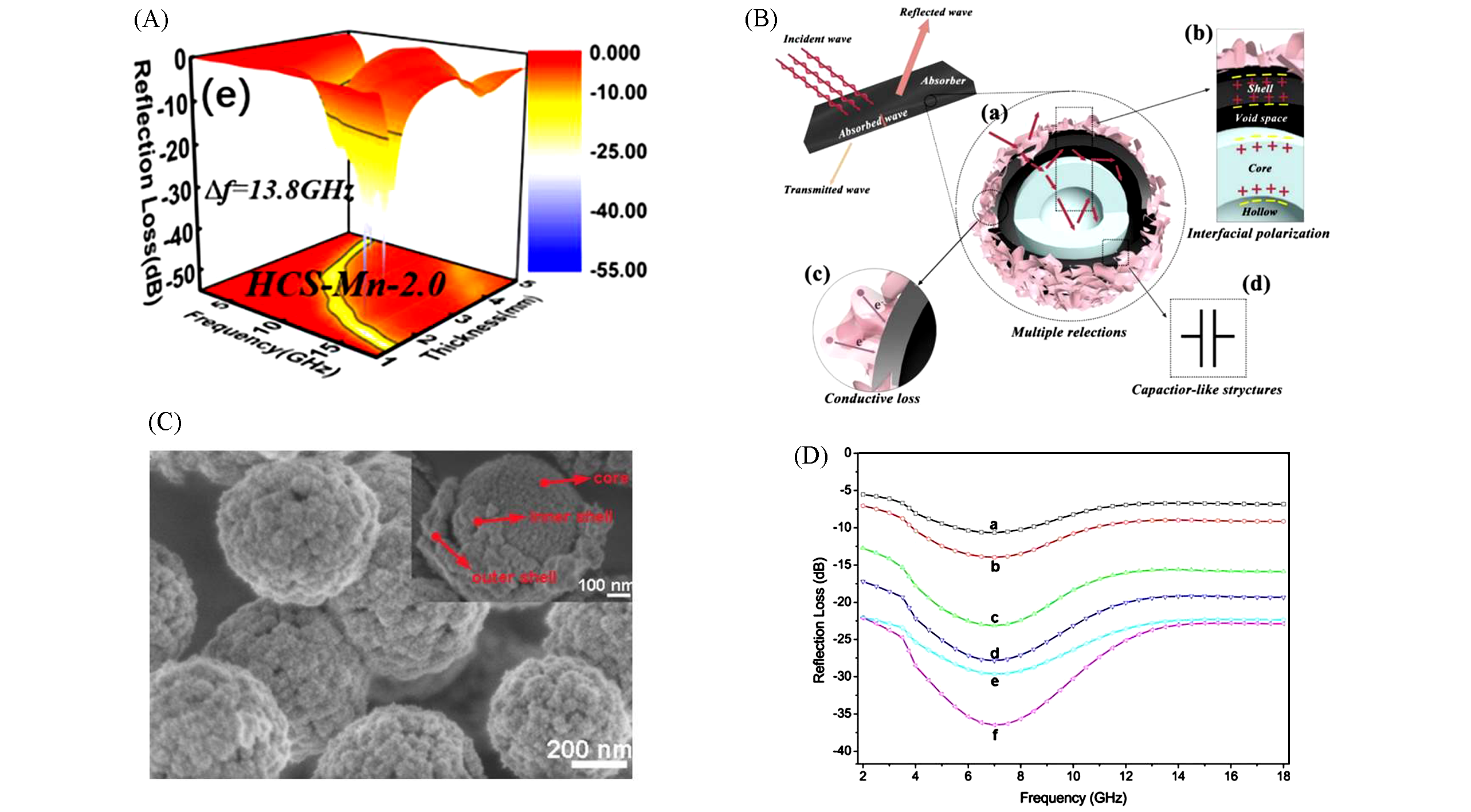

Fig.5 Reflection loss curves of HCS?Mn?2.0 with different thicknesses in the frequency range of 2—18 GHz(A)[43], scheme of microwave attenuation process in yolk?shell Fe3O4@C@MnO2 absorber(B)[44], FESEM image of the double?shelled Fe3O4@SnO2 yolk?shell microspheres and high?magni?cation FESEM image of a broken microsphere(inset)(C), microwave reflection loss curves of the epoxy resin composites respectively containing Fe3O4 particles(a), Fe3O4@SiO2 microspheres(b), single?shelled Fe3O4@SnO2 yolk?shell microspheres(c), and double?shelled Fe3O4@SnO2 yolk?shell microspheres(d—f) with diameters of 545, 626 and 720 nm(D)[45](A) Copyright 2020, Elsevier B. V. (B) Copyright 2020, Elsevier B. V. (C, D) Copyright 2013, American Chemical Society.

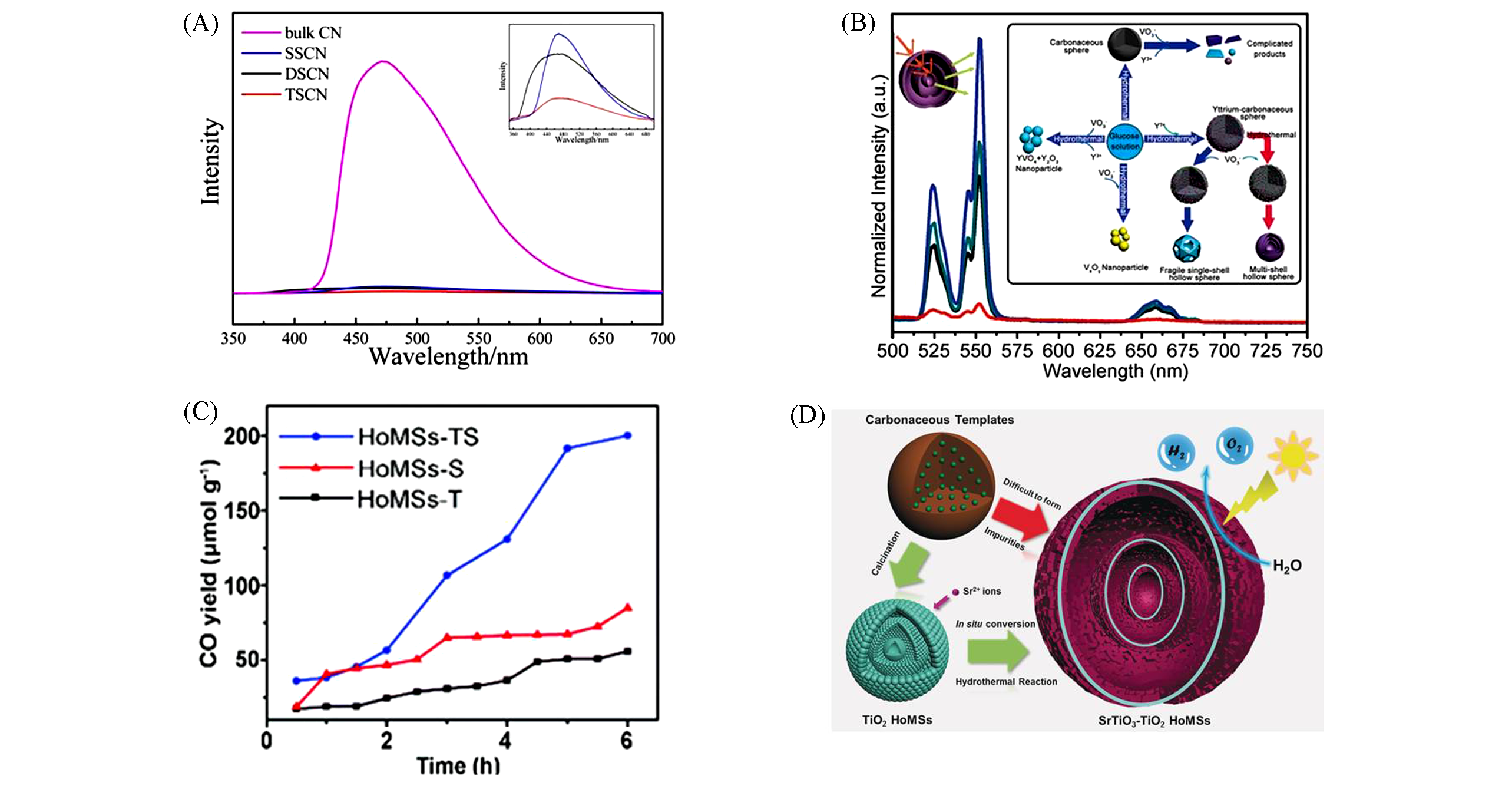

Fig.6 PL spectra of bulk g?C3N4 and g?C3N4 HoMSs with different shell numbers(A)[47], upconversion emission spectra of 3.0 mol% Yb3+ and 1.0 mol% Er3+ doped YVO4 multi?shell hollow spheres and illustration of the formation exploration for YVO4 multi?shell hollow spheres through various approaches(inset)(B)[48], CO yields of di?erent catalysts under UV?Vis irradiation(C)[50] and synthesis route of SrTiO3?TiO2 hollow multi‐shelled structures from hydrothermal reaction(D)[52](A) Copyright 2017, American Chemical Society. (B) Copyright 2017, Wiley?VCH. (C) Copyright 2019, Royal Society of Chemistry. (D) Copyright 2019, Wiley?VCH.

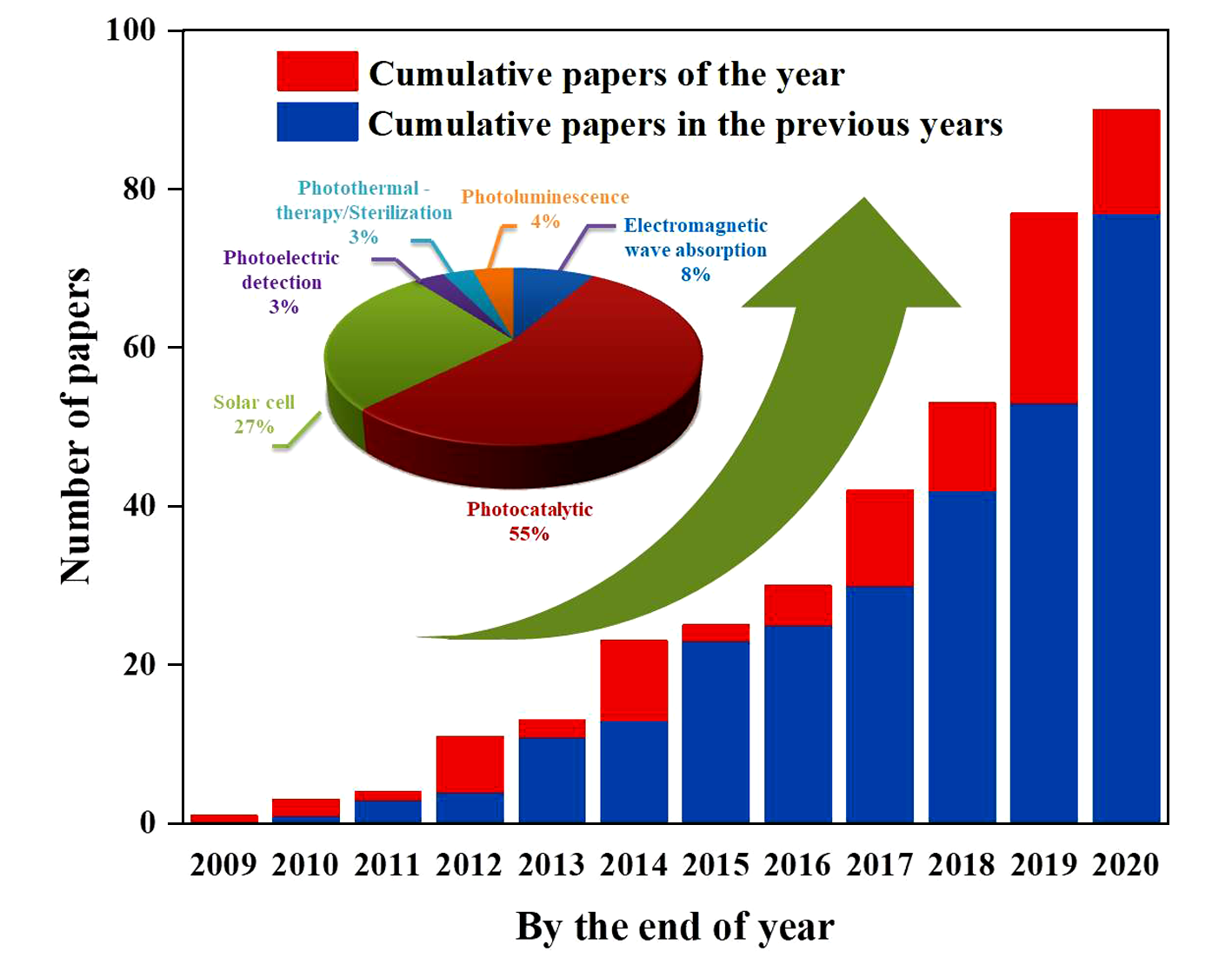

Fig.7 Literature statistics of HoMSs in the field of electromagnetic waves from 2009 to 2020 and the statistics of the proportion of HoMSs in the field of electromagnetic waves

| 1 | Cheng F., Environment and Sustainable Development,2015, 40(1), 126—127(程芳. 环境与可持续发展, 2015, 40(1), 126— 127) |

| 2 | Yang X. X., Li S. L., Wei P., Feng L. H., Frontier Science,2014, 8(1), 13—26(杨新兴, 李世莲, 尉鹏, 冯丽华. 前沿科学, 2014, 8(1), 13—26) |

| 3 | Xiang Z., Song Y., Xiong J., Pan Z., Wang X., Liu L., Liu R., Yang H., Lu W., Carbon,2019, 142, 20—31 |

| 4 | Jia Z., Lan D., Lin K., Qin M., Kou K., Wu G., Wu H., J. Mater. Sci., Mater. Electron.,2018, 29(20), 17122—17136 |

| 5 | Tian J., Zhu H., Chen J., Zheng X., Duan H., Pu K., Chen P., Small,2017, 13(22), 1700798 |

| 6 | Shcherbakova D. M., Verkhusha V. V., Nat. Methods,2013, 10(8), 751—754 |

| 7 | Ring E. F., Ammer K., Physiol. Meas.,2012, 33(3), R33—R46 |

| 8 | Shen J., Zhao L., Han G., Adv. Drug Delivery Rev.,2013, 65(5), 744—755 |

| 9 | Zhang P., Lou X. W., Adv. Mater.,2019, 31(29), 1900281 |

| 10 | Wang Z., Akter Monny S., Wang L., ChemNanoMat, 2020, 6(6), 881—888 |

| 11 | Hu F., Zhang Y., Chen G., Li C., Wang Q., Small,2015, 11(8), 985—993 |

| 12 | Zhang C., Gu Y., Teng G., Wang L., Jin X., Qiang Z., Ma W., ACS Appl. Mater. Interfaces,2020, 12(26), 29883—29898 |

| 13 | Iwaguch S., Matsumura K., Tokuoka Y., Wakui S., Kawashima N., Colloids Surf. B,2002, 25(4), 299—304 |

| 14 | Song K., Mohseni M., Taghipour F., Water Res., 2016, 94, 341—349 |

| 15 | Garofalo M., Villa A., Brunialti E., Crescenti D., Dell’Omo G., Kuryk L., Vingiani A., Mazzaferro V., Ciana P., Nanotheranostics, 2020, 5(1), 1—7 |

| 16 | Xiao T. Q., Xie H. L., Deng B., Du G. H., Chen R. C., Acta Opt. Sin., 2014, 34(1), 9—23(肖体乔, 谢红兰, 邓彪, 杜国浩, 陈荣昌. 光学学报, 2014, 34(1), 9—23) |

| 17 | Ma L. D., Progress in Physics, 2014, 34(2), 47—117(马礼敦. 物理学进展, 2014, 34(2), 47—117) |

| 18 | Li M., Mao D., Wan J., Wang F., Zhai T., Wang D., Inorg. Chem. Front., 2019, 6(8), 1968—1972 |

| 19 | Lien D. H., Dong Z., Retamal J. R. D., Wang H. P., Wei T. C., Wang D., He J. H., Cui Y., Adv. Mater., 2018, 30(34), 1801972 |

| 20 | Zhang X. J., Zhu J. Q., Yin P. G., Guo A. P., Huang A. P., Guo L., Wang G. S., Adv. Funct. Mater., 2018, 28(49), 1800761 |

| 21 | Xiong J., Xiang Z., Deng B., Wu M., Yu L., Liu Z., Cui E., Pan F., Liu R., Lu W., Appl. Surf. Sci., 2020, 513, 145778 |

| 22 | Wang Y., Han B., Chen N., Deng D., Guan H., Wang Y., J. Alloys Compd., 2016, 676, 224—230 |

| 23 | Zhao B., Shao G., Fan B., Zhao W., Xie Y., Zhang R., J. Mater. Chem. A, 2015, 3(19), 10345—10352 |

| 24 | Zhou C., Geng S., Xu X., Wang T., Zhang L., Tian X., Yang F., Yang H., Li Y., Carbon, 2016, 108, 234—241 |

| 25 | Wei Y., Yang N., Huang K., Wan J., You F., Yu R., Feng S., Wang D., Adv. Mater., 2020, 32(44), 2002556 |

| 26 | Lai X., Halpert J. E., Wang D., Energy Environ. Sci., 2012, 5(2), 5604—5618 |

| 27 | Mao D., Wan J., Wang J., Wang D., Adv. Mater., 2018, 31(38), 1802874 |

| 28 | Zong L., Xu P., Ding Y., Zhao K., Wang Z., Yan X., Yu R., Chen J., Xing X., Small, 2015, 11(23), 2768—2773 |

| 29 | Zhang X., Peng J., Song Y., Chen Y., Lu F., Gao W., Biosens. Bioelectron., 2019, 133, 125—132 |

| 30 | Ren H., Yu R., Inorg. Chem. Front., 2019, 6(9), 2239—2259 |

| 31 | Li B., Mao B., He T., Huang H., Wang X., ACS Appl. Electron. Mater., 2019, 1(10), 2140—2149 |

| 32 | Xu H., Yin X., Zhu M., Han M., Hou Z., Li X., Zhang L., Cheng L., ACS Appl. Mater. Interfaces, 2017, 9(7), 6332—6341 |

| 33 | Yang S., You W. B., Qiu L. C., Che R. C., Yang S. J., Chin. Sci. Bull., 2018, 63(8), 712—724(杨盛, 游文彬, 裘立成, 车仁超, 杨士军. 科学通报, 2018, 63(8), 712—724) |

| 34 | Gao T., Jelle B. P., Gustavsen A., Appl. Phys. A, Mater. Sci. Process., 2012, 110(1), 65—70 |

| 35 | Wei Y., Wan J., Yang N., Yang Y., Ma Y., Wang S., Wang J., Yu R., Gu L., Wang L., Wang L., Huang W., Wang D., Natl. Sci. Rev., 2020,7(11), 1638—1646 |

| 36 | Wang B., Li R., Zhang Z., Zhang W., Yan X., Wu X., Cheng G., Zheng R., J. Mater. Chem. A, 2017, 5(27), 14415—14421 |

| 37 | Pang R., Hu X., Zhou S., Sun C., Yan J., Sun X., Xiao S., Chen P., Chem. Commun., 2014, 50(83), 12493—12496 |

| 38 | Wang X., Liao M., Zhong Y., Zheng J. Y., Tian W., Zhai T., Zhi C., Ma Y., Yao J., Bando Y., Golberg D., Adv. Mater., 2012, 24(25), 3421—3425 |

| 39 | Dong Z., Ren H., Hessel C. M., Wang J., Yu R., Jin Q., Yang M., Hu Z., Chen Y., Tang Z., Zhao H., Wang D., Adv. Mater., 2014, 26(6), 905—909 |

| 40 | Qi J., Zhao K., Li G., Gao Y., Zhao H., Yu R., Tang Z., Nanoscale, 2014, 6(8), 4072—4077 |

| 41 | Dong Z., Lai X., Halpert J. E., Yang N., Yi L., Zhai J., Wang D., Tang Z., Jiang L., Adv. Mater., 2012, 24(8), 1046—1049 |

| 42 | Wei Y. Z., Hollow Multi⁃shelled Structures of Complex Metal Oxide: Preparation and Application in Photocatalysis, University of Science and Technology Beijing, Beijing, 2019(魏延泽. 复合金属氧化物中空多壳结构的制备及其光催化应用研究, 北京: 北京科技大学, 2019) |

| 43 | Yang L., Lv H., Li M., Zhang Y., Liu J., Yang Z., Chem. Eng. J., 2020, 392, 123666 |

| 44 | Yang Z., Li M., Zhang Y., Yang L., Liu J., Wang Y., He Q., J. Alloys Compd., 2020, 817, 152795 |

| 45 | Liu J., Cheng J., Che R., Xu J., Liu M., Liu Z., J. Phys. Chem. C, 2012, 117(1), 489—495 |

| 46 | Tao J., Zhou J., Yao Z., Jiao Z., Wei B., Tan R., Li Z., Carbon,2021, 172, 542—555 |

| 47 | Tong Z., Yang D., Li Z., Nan Y., Ding F., Shen Y., Jiang Z., ACS Nano, 2017, 11(1), 1103—1112 |

| 48 | Zong L., Xu J., Jiang S., Zhao K., Wang Z., Liu P., Zhao H., Chen J., Xing X., Yu R., Adv. Mater., 2017, 29(9), 1604377 |

| 49 | Wang L., Wan J., Zhao Y., Yang N., Wang D., J. Am. Chem. Soc., 2019, 141(6), 2238—2241 |

| 50 | Jiang S., Zhao K., Al⁃Mamun M., Zhong Y. L., Liu P., Yin H., Jiang L., Lowe S., Qi J., Yu R., Wang D., Zhao H., Inorg. Chem. Front., 2019, 6(7), 1667—1674 |

| 51 | Sun L., Han X., Jiang Z., Ye T., Li R., Zhao X., Han X., Nanoscale,2016, 8(26), 12858—12862 |

| 52 | Wei Y., Wang J., Yu R., Wan J., Wang D., Angew. Chem. Int. Ed., 2019, 58(5), 1422—1426 |

| 53 | You F., Wan J., Qi J., Mao D., Yang N., Zhang Q., Gu L., Wang D., Angew. Chem. Int. Ed., 2020,59(2), 721—724 |

| 54 | Zhang P., Guan B. Y., Yu L., Lou X. W., Chem, 2018, 4(1), 162—173 |

| 55 | Waqas M., Wei Y., Mao D., Qi J., Yang Y., Wang B., Wang D., Nano Res., 2017, 10(11), 3920—3928 |

| 56 | Wang S., Zhang X., Li S., Fang Y., Pan L., Zou J. J., J. Hazard. Mater., 2017, 331, 235—245 |

| 57 | Wang J., Wan J., Yang N., Li Q., Wang D., Nat. Rev. Chem., 2020, 4(3), 159—168 |

| 58 | Wang H., Mao D., Qi J., Zhang Q., Ma X., Song S., Gu L., Yu R., Wang D., Adv. Funct. Mater., 2019, 29(15), 1806588 |

| 59 | Wang H., Qi J., Yang N., Cui W., Wang J., Li Q., Zhang Q., Yu X., Gu L., Li J., Yu R., Huang K., Song S., Feng S., Wang D., Angew. Chem. Int. Ed., 2020, 59(44), 19691—19695 |

| [1] | 陈朝阳, 薛玉瑞, 李玉良. 石墨炔零价金属原子催化剂的合成及应用[J]. 高等学校化学学报, 2022, 43(5): 20220063. |

| [2] | 王鹏, 毛丹, 万家炜, 祁琪, 杜江, 王丹. 中空多壳层TiO2填充对环氧树脂复合材料力学性能的影响[J]. 高等学校化学学报, 2021, 42(10): 3218. |

| [3] | 孙辉, 赖小勇. 中空多壳层结构材料的制备及气体传感应用研究进展[J]. 高等学校化学学报, 2020, 41(5): 855. |

| [4] | 及媛媛,王海军,李元峰 . Aa1Dd1-Aa2Dd2型氢键体系的网络结构参数[J]. 高等学校化学学报, 2007, 28(3): 506. |

| [5] | 杨冉,陈晓岚,李萍,屈凌波 . 荧光法研究三种黄酮小分子与溶菌酶的相互作用[J]. 高等学校化学学报, 2006, 27(9): 1673. |

| [6] | 王霞, 袁满雪, 赖城明, 刘洁, 李正名. 应用分子图形学、分子力学、量子化学及静电势研究农药分子结构与性能关系(Ⅸ)──结构参数及计算方法的选择对提高磺酰脲类除草剂活性预报准确性的影响[J]. 高等学校化学学报, 1997, 18(1): 60. |

| [7] | 黄卡玛, 刘永清, 唐敬贤, 赵军, 王保义. 电磁波对化学反应非致热作用的实验研究[J]. 高等学校化学学报, 1996, 17(5): 764. |

| [8] | 吴向东, 郭贤权, 何炳林. 新型醋酸乙烯酯/二乙烯苯共聚物的研究(Ⅱ)──醇解物的制备、结构及其性能[J]. 高等学校化学学报, 1995, 16(6): 989. |

| [9] | 何炳林, 郭贤权, 杨志欣, 何丹, 史秀萍. 三烯丙基异氰尿酸酯交联共聚物的研究(Ⅱ)——醇解物的制备、结构及其性能[J]. 高等学校化学学报, 1990, 11(8): 873. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||