Chem. J. Chinese Universities ›› 2022, Vol. 43 ›› Issue (2): 20210619.doi: 10.7503/cjcu20210619

• Material Chemistry • Previous Articles Next Articles

CHU Yao1, WANG Shuo1, ZHANG Zinuo1, WANG Yibo1, CAI Yibing1,2( )

)

Received:2021-09-16

Online:2022-02-10

Published:2021-11-11

Contact:

CAI Yibing

E-mail:yibingcai@jiangnan.edu.cn

Supported by:CLC Number:

TrendMD:

CHU Yao, WANG Shuo, ZHANG Zinuo, WANG Yibo, CAI Yibing. Preparation and Properties of Cu Particles Loaded Foam-based Phase Change Composites[J]. Chem. J. Chinese Universities, 2022, 43(2): 20210619.

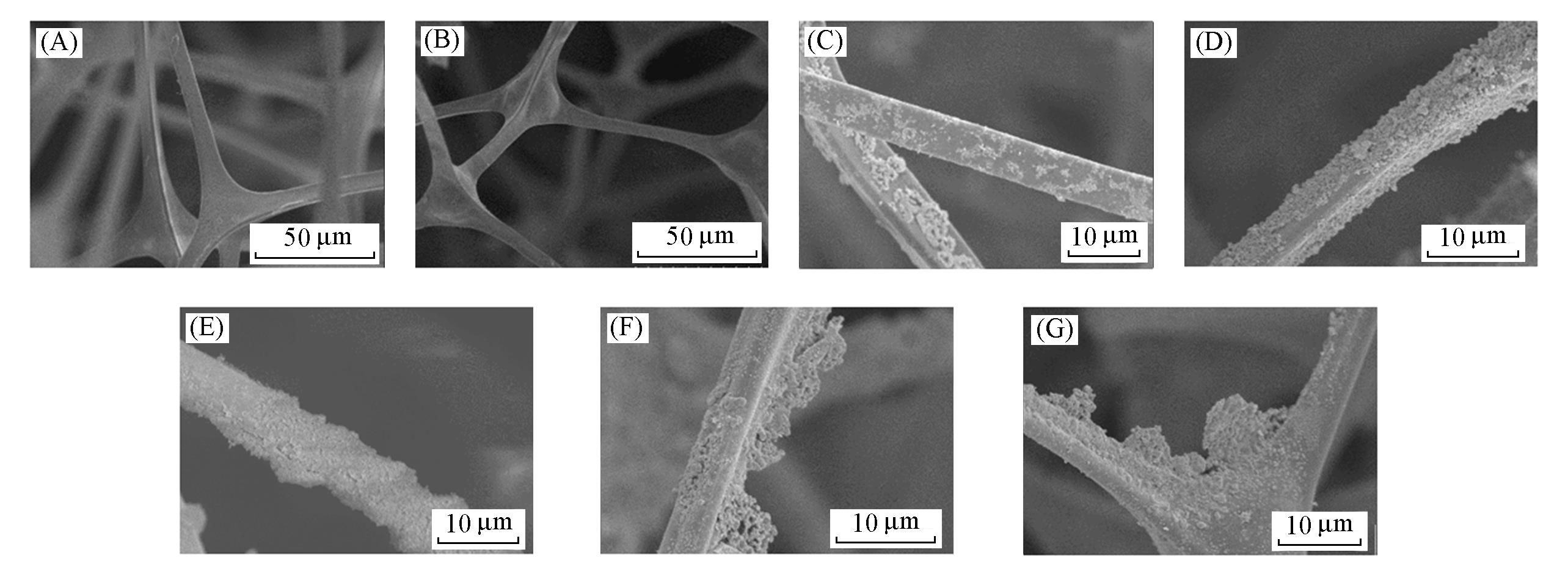

Fig.1 SEM images of internal skeleton of MF, CF and CF@Cu?x(A) MF; (B) CF; (C)CF@Cu-0.5; (D) CF@Cu-0.75; (E) CF@Cu-1.0; (F) CF@Cu-1.25; (G) CF@Cu-1.5.

| Sample | Tmi/℃ | Tmp/℃ | Tme/℃ | ΔHm/(J·g-1) | Tci/℃ | Tcp/°C | Tce/℃ | ΔHc/(J?g-1) |

|---|---|---|---|---|---|---|---|---|

| PEG 2000 | 41.6 | 52.3 | 57.1 | 178.3 | 23.7 | 28.8 | 35.8 | 164.0 |

| CF@PEG | 39.3 | 51.9 | 56.9 | 166.1 | 26.4 | 32.4 | 37.0 | 161.0 |

| CF@Cu?0.5/PEG | 38.8 | 52.4 | 55.7 | 153.3 | 26.9 | 33.3 | 38.3 | 146.0 |

| CF@Cu?0.75/PEG | 38.5 | 52.4 | 55.5 | 150.3 | 27.0 | 32.8 | 37.7 | 144.4 |

| CF@Cu?1.0/PEG | 38.9 | 52.4 | 56.6 | 145.2 | 26.5 | 32.2 | 36.6 | 141.2 |

| CF@Cu?1.25/PEG | 41.5 | 52.9 | 56.6 | 142.9 | 26.6 | 32.1 | 35.8 | 135.3 |

| CF@Cu?1.5/PEG | 39.0 | 53.1 | 56.8 | 139.1 | 26.7 | 31.3 | 36.0 | 133.0 |

Table 1 Detailed thermophysical parameters of PEG, CF@PEG and CF@Cu-x/PEG

| Sample | Tmi/℃ | Tmp/℃ | Tme/℃ | ΔHm/(J·g-1) | Tci/℃ | Tcp/°C | Tce/℃ | ΔHc/(J?g-1) |

|---|---|---|---|---|---|---|---|---|

| PEG 2000 | 41.6 | 52.3 | 57.1 | 178.3 | 23.7 | 28.8 | 35.8 | 164.0 |

| CF@PEG | 39.3 | 51.9 | 56.9 | 166.1 | 26.4 | 32.4 | 37.0 | 161.0 |

| CF@Cu?0.5/PEG | 38.8 | 52.4 | 55.7 | 153.3 | 26.9 | 33.3 | 38.3 | 146.0 |

| CF@Cu?0.75/PEG | 38.5 | 52.4 | 55.5 | 150.3 | 27.0 | 32.8 | 37.7 | 144.4 |

| CF@Cu?1.0/PEG | 38.9 | 52.4 | 56.6 | 145.2 | 26.5 | 32.2 | 36.6 | 141.2 |

| CF@Cu?1.25/PEG | 41.5 | 52.9 | 56.6 | 142.9 | 26.6 | 32.1 | 35.8 | 135.3 |

| CF@Cu?1.5/PEG | 39.0 | 53.1 | 56.8 | 139.1 | 26.7 | 31.3 | 36.0 | 133.0 |

| 1 | Latibari S. T., Sadrameli S. M., Sol. Energy, 2018, 170, 1130—1161 |

| 2 | Mofijur M., Mahlia T. M. I., Silitonga A. S., Ong H. C., Silakhori M., Hasan M. H., Putra N., Rahman S. M. A., Energies, 2019, 12(16), 3167 |

| 3 | Gondora W., Doudin K., Nowakowski D. J., Appl. Energy, 2016, 182, 274—281 |

| 4 | Zhou Z. H., Zhang Z. M., Zuo J., Huang K., Zhang L. Y., Renew. Sust. Energy Rev., 2015, 48, 692—703 |

| 5 | Wei Y. H., Li J. J., Sun F. R., Wu J. R., Zhao L. J., Green Chem., 2018, 20(8), 1858—1865 |

| 6 | Wang W. W., Cai Y. B., Du M. Y., Hou X. B., Liu J. Y., Ke H. Z., Wei Q. F., ACS Appl. Mater. Interfaces, 2019, 11(35), 31997—32007 |

| 7 | Xiao Q. Q., Fan J. X., Li L., Xu T., Yuan W. H., Energy, 2018, 165, 1240—1247 |

| 8 | Golestaneh S. I., Mosallanejad A., Karimi G., KhashiM., Appl. Energy, 2016, 182, 409—417 |

| 9 | Zhang Q. X., Chen J. H., Lu H. B., Tang W., Lu Y., Gao Y. Z., Chem. J. Chinese Universities, 2014, 35(10), 2258—2264(张秋香, 陈建华, 陆洪彬, 唐伟, 陆玉, 高扬之. 高等学校化学学报, 2014, 35(10), 2258—2264) |

| 10 | Huang X. B., Chen X., Li A., Atinafu D., Gao H. Y., Dong W. J., Wang G., Chem. Eng. J., 2019, 356, 641—661 |

| 11 | Xu Y., Ren Q. L., Zheng Z. J., He Y. L., Appl.Energy, 2017, 193, 84—95 |

| 12 | Yang H. Y., Wang Y. Z., Yu Q. Q., Cao G. L., Sun X. H., Yang R., Zhang Q., Liu F., Di X., Li J., Wang C. Y., Li G. L., Energy, 2018, 159, 929—936 |

| 13 | Li M., Guo Q. G., Nutt S., Sol. Energy, 2017, 146, 1—7 |

| 14 | Qi G. Q., Yang J., Bao R. Y., Liu Z. Y., Yang W., Xie B. H., Yang M. B., Carbon, 2015, 88, 196—205 |

| 15 | Zhang L., Zhang P., Wang F., Kang M., Li R. Q., MouY. R., HuangY. H., Appl. Therm. Eng., 2016, 101, 217—223 |

| 16 | Xue F., Qi X. D., Huang Q. T., Tang C. Y., Zhang N., Wang Y., Chem. Eng. J., 2021, 419, 129620 |

| 17 | Wang Z. Y., Situ W. F., Li X. X., Appl. Therm. Eng., 2017, 123, 1006—1012 |

| 18 | Yang J., Tang L. S., Bao R. Y., Bai L., Liu Z. Y., Yang W., Xie B. H., Yang M. B., J. Mater. Chem. A, 2016, 4(48), 18841—18851 |

| 19 | Chen L. J., Zou R. Q., Xia W., Liu Z. P., Shang Y. Y., Zhu J. L., Wang Y. X., Lin J. H., Xia D. G., Cao A. Y., ACS Nano, 2012, 6(12), 10884—10892 |

| 20 | Wang H. L., Gao Q. M., Chem. J. Chinese Universities, 2011, 32(3), 462—470(王焕磊, 高秋明. 高等学校化学学报, 2011, 32(3), 462—470) |

| 21 | Li Y. L., Li J. H., Deng Y., Guan W. M., Wang X., Qian T. T., Appl. Energy, 2016, 171, 37—45 |

| 22 | Zhang Y., Wang J. S., Qiu J. J., Jin X., Umair M. M., Lu R. W., Zhang S. F., Appl. Energy, 2019, 237, 83—90 |

| 23 | Zhang H. Y., Wang L. L., Xi S. B., Zhang H. Y., Wang L. L., Xi S. B., Xie H. Q., Yu W., Renew. Energy, 2012, 175, 307—317 |

| 24 | Song S. K., Qiu F., Zhu W. T., Guo Y., Sol.Energy Mater. Sol. Cells, 2019, 193, 237—245 |

| 25 | Xiao Y. Y., Bai D. Y., Xie Z. P., Yang Z. P., Yang J. H., Compos. Part A, Appl. Sci. Manuf.2021, 146, 106420 |

| 26 | Oya T., Nomura T., Okinaka N., Tomohiro A., Appl. Therm. Eng., 2012, 40, 373—377 |

| 27 | Wang B., Luo X. Y., Wang C., Mater. Review, 2020, 34(18), 18159—18164(王斌, 罗晓宇, 王琛. 材料导报, 2020, 34(18), 18159—18164) |

| 28 | Al⁃Tabbakh A. A., Karatepe N., Al⁃Zubaidi A. B., Benchaabane A., Mahmood N. B., Int. J. Energy Res., 2019, 43(5), 1903—1911 |

| 29 | Wu H. Y., Li S. T., Wu H. Y., Li S. T., Shao W. W., Jin X. Z., Qi X. D., Yang J. H., Zhou Z. W., Wang Y., Chem. Eng. J., 2020, 379, 122373 |

| 30 | Xue F., Jin X. Z., Xie X., Qi J. H., Wang Y., Nanoscale, 2019, 11, 18691—18701 |

| 31 | Song J. Y., Cai Y. B., Du M. Y., Hou X. B., Huang F. L., Wei Q. F., ACS Appl. Bio. Mater., 2020, 3(12), 8923—8932 |

| [1] | WANG Mengyu, CAO Simin, LI Haoyang, ZHANG Mengjie, LI Dong, ZHAO Zenan, XU Jianhua. Fluorescence Resonance Energy Transfer Between Coenzyme NADH and Tryptophan [J]. Chem. J. Chinese Universities, 2020, 41(11): 2473. |

| [2] | MA Xiangying, LIAO Yanjun, QIN Fanghong, YIN Yuanhao, HUANG Zaiyin, CHEN Qifeng. Study on the Photocatalytic Performance of Carbon Doped g-C3N4 Based on in situ Photomicrocalorimeter-fluorescence Spectrometry [J]. Chem. J. Chinese Universities, 2020, 41(11): 2526. |

| [3] | LI Honghong,GENG Keying,TIAN Fuyue,GU Fang,WANG Haijun. Regulation of Phase State of Dipolar Janus Particles and Its Application † [J]. Chem. J. Chinese Universities, 2020, 41(5): 1042. |

| [4] | XIAO Biyuan,QIU Jiangyuan,QIN Fanghong,WAN Ting,XU Yaqun,NONG Xiaohui,HUANG Zaiyin. Study on Particle Size Effect on Adsorption Thermodynamics and Kinetics of Cubic Nano-Cu2O † [J]. Chem. J. Chinese Universities, 2019, 40(10): 2214. |

| [5] | YU Kaile,PAN Xinyu,ZHANG Zhengfang,WANG Qiang. Determination of Solubility Parameters of Imidazolyl Acetate Ionic Liquid by Inverse Gas Chromatography and Hansen Solubility Parameters† [J]. Chem. J. Chinese Universities, 2018, 39(5): 1048. |

| [6] | LIU Shujing, LI Jiangtao, GU Fang, WANG Haijun. Phase Structure of Aa Type of Patchy Colloids† [J]. Chem. J. Chinese Universities, 2017, 38(10): 1888. |

| [7] | YAO Jian, WANG Jianping, WEI Yao, WANG Xuechen, LI Wei, ZHANG Xingxiang. Synthesis and Characterization of Polyprrole Microcapcule Containing ZnCl2 Solution† [J]. Chem. J. Chinese Universities, 2016, 37(10): 1907. |

| [8] | LI Long, ZHANG Sisi, LIU Yuanhui, GUO Yafei, DENG Tianlong. Heat Capacities and Ion-interaction of Lithium Tetraborate Aqueous Solution System† [J]. Chem. J. Chinese Universities, 2016, 37(2): 349. |

| [9] | HU Biao, ZHOU Peng, PAN Chengling, DU Yong, LIU Shuhong, LI Yiwei, HAN Jiangjun. Theoretical Study on the Binary Phase Diagrams of the Zr-X (X=Li, Na, K, Sc, Hf) Systems† [J]. Chem. J. Chinese Universities, 2015, 36(10): 1939. |

| [10] | LI Zhaowan, QIAO Zhanping, CHEN Xin, DANG Yuanlin, YANG Qichao. Equilibria for the CsBr-TmBr3-H2O and CsBr-TmBr3-HBr(~13%)-H2O Systems at 298.15 K and Thermodynamic and Fluorescent Properties of New Solid-phase Compound [J]. Chem. J. Chinese Universities, 2015, 36(9): 1759. |

| [11] | ZHAO Zuofei, LI Yuanfeng, YAO Ning. Thermodynamic Properties of a Binary Self-condensing Vinyl Polymerization System in the Presence of Core Initiators† [J]. Chem. J. Chinese Universities, 2015, 36(8): 1648. |

| [12] | KUANG Jingzhong, YUAN Weiquan, XU Liyong, LI Lin, HUANG Zhen. Effect of La(NO3)3 and Pr(NO3)3 on Kinetic of Dehydroxylation of Kaolinite† [J]. Chem. J. Chinese Universities, 2015, 36(7): 1395. |

| [13] | LIU Zuojiao, FAN Gaochao, HE Liangming, DIAO Kaisheng, HUANG Zaiyin, TAN Xuecai. Temperature and Morphology Effect on Surface Thermodynamic Functions of Ag3PO4 Microcrystals† [J]. Chem. J. Chinese Universities, 2015, 36(7): 1385. |

| [14] | LIU Xiaolin, WANG Lude, HUANG Zaiyin, LIU Zuojiao, LI Xingxing. Thermodynamic Functions of Nano Zinc Oxide Acquired by Microcalorimetry and Electrochemical Methods† [J]. Chem. J. Chinese Universities, 2015, 36(3): 539. |

| [15] | XUE Yunna, LI Jiaoyi, HAO Zhijun, WAN Hong, ZHAO Haixia, Li Chunying, DU Yongmei, Lu Juyou, Yu Qinwei, Lü Jian. Synthesis, Thermal Decomposition Mechanism and Kinetic Equation of Polyhedral Boron Hydride Compound [(C2H5)4N]2B10H10 with High Enthalpy of Combustion† [J]. Chem. J. Chinese Universities, 2015, 36(2): 375. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||