Chem. J. Chinese Universities ›› 2014, Vol. 35 ›› Issue (10): 2265.doi: 10.7503/cjcu20140365

• Polymer Chemistry • Previous Articles Next Articles

HE Zhihang, LIU Jia, JIAO Jianjin, WU Guifang, XIAO Xiufeng*( )

)

Received:2014-04-18

Online:2014-10-10

Published:2014-09-12

Contact:

XIAO Xiufeng

E-mail:xfxiao@fjnu.edu.cn

Supported by:CLC Number:

TrendMD:

HE Zhihang, LIU Jia, JIAO Jianjin, WU Guifang, XIAO Xiufeng. Fabrication and Characterization of Poly(L-lactic acid)-polycaprolactone Composite Nanofiber Scaffolds†[J]. Chem. J. Chinese Universities, 2014, 35(10): 2265.

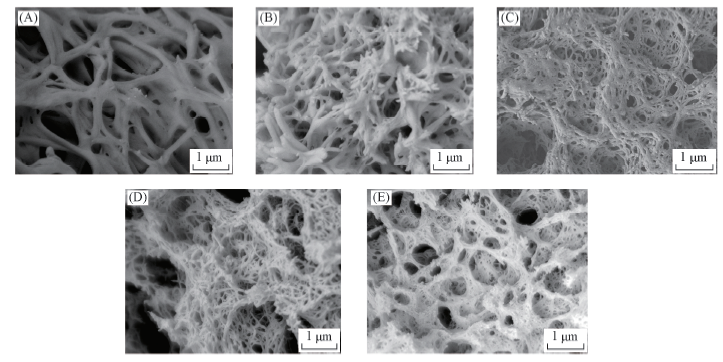

Fig.2 SEM images of PLLA-PCL scaffolds prepared in dioxane/ethanol(90∶10, mass ratio) with different mass ratios of PLLA/PCL Mass ratio of PLLA/PCL: (A) 50∶50; (B) 60∶40; (C) 70∶30; (D) 80∶20; (E) 90∶10.

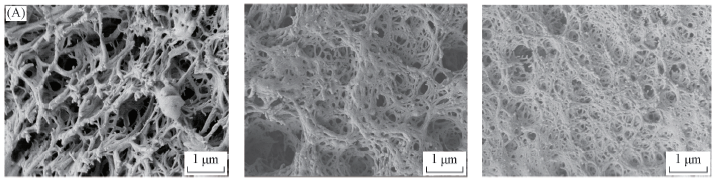

Fig.3 SEM images of PLLA-PCL scaffolds prepared at -10 ℃ with different mass ratios of dioxane/ethanol Mass ratio of dioxane/ethanol: (A) 85∶15; (B) 90∶10; (C) 95∶5.

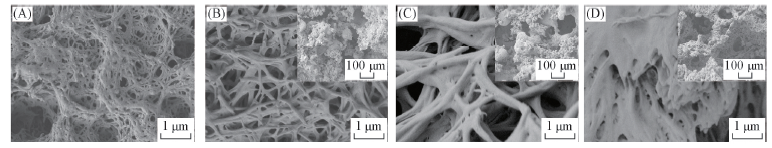

Fig.4 SEM images of PLLA-PCL scaffolds prepared at -10 ℃ with different mass ratios of porogen Mass ratio of porogen: (A) 0∶1; (B) 10∶1; (C) 20∶1; (D) 30∶1.

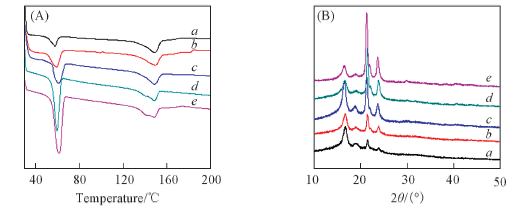

Fig.5 DSC curves(A) and XRD patterns(B) of PLLA-PCL scaffolds prepared in dioxane/ethanol (90∶10, mass ratio) with different mass ratios of PLLA/PCL Mass ratio of PLLA/PCL: (A) 90∶10; (B) 80∶20; (C) 70∶30; (D) 60∶40; (E) 50∶50.

| Mass ratio of PLLA/PCL | Mass ratio of dioxane/ethanol | Mass ratio of porogen/solution | Gelation temperature/℃ | Porosity(%) |

|---|---|---|---|---|

| 90∶10 | 90∶10 | 0 | -10 | 92.04±0.28 |

| 80∶20 | 90∶10 | 0 | -10 | 92.53±0.20 |

| 70∶30 | 90∶10 | 0 | -10 | 93.02±0.33 |

| 60∶40 | 90∶10 | 0 | -10 | 94.48±0.29 |

| 50∶50 | 90∶10 | 0 | -10 | 94.76±0.30 |

| 70∶30 | 90∶10 | 0 | -20 | 93.93±0.29 |

| 70∶30 | 85∶15 | 0 | -10 | 94.55±0.24 |

| 70∶30 | 95∶5 | 0 | -10 | 92.39±0.31 |

| 70∶30 | 90∶10 | 0.5∶1 | -10 | 94.84±0.32 |

| 70∶30 | 90∶10 | 1∶1 | -10 | 95.75±0.22 |

| 70∶30 | 90∶10 | 1.5∶1 | -10 | 90.44±0.24 |

Table 1 Porosity of PLLA-PCL composite scaffolds at different fabrication conditions

| Mass ratio of PLLA/PCL | Mass ratio of dioxane/ethanol | Mass ratio of porogen/solution | Gelation temperature/℃ | Porosity(%) |

|---|---|---|---|---|

| 90∶10 | 90∶10 | 0 | -10 | 92.04±0.28 |

| 80∶20 | 90∶10 | 0 | -10 | 92.53±0.20 |

| 70∶30 | 90∶10 | 0 | -10 | 93.02±0.33 |

| 60∶40 | 90∶10 | 0 | -10 | 94.48±0.29 |

| 50∶50 | 90∶10 | 0 | -10 | 94.76±0.30 |

| 70∶30 | 90∶10 | 0 | -20 | 93.93±0.29 |

| 70∶30 | 85∶15 | 0 | -10 | 94.55±0.24 |

| 70∶30 | 95∶5 | 0 | -10 | 92.39±0.31 |

| 70∶30 | 90∶10 | 0.5∶1 | -10 | 94.84±0.32 |

| 70∶30 | 90∶10 | 1∶1 | -10 | 95.75±0.22 |

| 70∶30 | 90∶10 | 1.5∶1 | -10 | 90.44±0.24 |

| [1] | Hutmacher D. W., Schantz T., Zein I., J. Biomed. Mater. Res. A,2001, 55(2), 203—216 |

| [2] | Woodfield T. B. F., Malda J., Wijn J., Biomaterials,2004, 25(18), 4149—4161 |

| [3] | Sun S. F., Li N. N., Liu M., Liu Y. C., Zhang Y. C., Zhou Y. M., Chem. J. Chinese Universities,2012, 33(12), 2827—2832(孙淑芬, 李男男, 刘敏, 刘译聪, 张英超, 周延民. 高等学校化学学报, 2012, 33(12), 2827—2832) |

| [4] | Tuli R., Li W. J., Tuan R. S., Arthritis Res. Ther., 2003, 5(5), 235—238 |

| [5] | Hutmacher D. W., Schantz T., Zein I., J. Biomed. Mater. Res. A,2001, 55(2), 203—216 |

| [6] | Xiao X. F., Ding X. H., Liu S. Q., Acta Materiae Compositae Sinica,2010, 27(6), 100—105 |

| (肖秀峰, 丁晓红, 刘淑琼. 复合材料学报, 2010, 27(6), 100—105) | |

| [7] | Yang J. M., Shyu J. S., Chen H. L., Polym. Eng. Sci., 1997, 37(7), 1182—1187 |

| [8] | Qian H. T., Bei J. Z., Wang S. G., Polym. Degrad. Stab., 2000, 68(3), 423—429 |

| [9] | DellErba R., Groeninckx G., Maglio G., Polymer,2001, 42(18), 7831—7840 |

| [10] | Liu N.H., Miao Y. E., Qi F. Z., Gu J. Y.,Fudan University Journal of Medical Sciences, 2014, (1), 34—39 |

| (刘宁华, 缪月娥, 亓发芝, 顾建英. 复旦学报, 2014, (1), 34—39) | |

| [11] | Li Y. D., Xu Y., Zhou Q., Song L., Liu W., Gan Y. B., Li P., Li S. T., Mo X. M., J. Third Mil. Med. Univ., 2014, 36(9), 914—918 |

| (李玉东, 徐源, 周强, 宋磊, 刘威, 甘翼博, 李培, 李松涛, 莫秀梅. 第三军医大学学报, 2014, 36(9), 914—918) | |

| [12] | Langer R., Vacanti J. P., Science,1993, 260, 920—926 |

| [13] | Li H.Q., Zhang C., Polymer Physics, Chemical Industry Press, Beijing, 2007, 94—95 |

| (励杭泉, 张晨. 聚合物物理学, 北京: 化学工业出版社, 2007, 94—95) | |

| [14] | Ji G. L., Zhu B. K., Cui Z. Y., Polymer,2007, 48(21), 6415—6425 |

| [15] | Ramiro D. E., Gabriel G., Giovanni M., Polymer,2001, 42(18), 7831—7840 |

| [16] | Ren J., Yang Jun., Ren T. B., Polymer Bulletin,2006, 12, 51—56 |

| (任杰, 杨军, 任天斌. 高分子通报, 2006, 12, 51—56) | |

| [17] | Zhang A. J., J. Shangdong University, 2010, 40(3), 86—90 |

| (张爱娟. 山东大学学报, 2010, 40(3), 86—90) | |

| [18] | Liu Y., Zhong K. N., Hu W. Y., J. Mater. Sci. Engin., 1997, 15(1), 63—65 |

| (刘羽, 钟康年, 胡文云. 材料科学与工程学报, 1997, 15(1), 63—65) | |

| [19] | Miyaji F., Iwai M., Kokubo T., J. Mater. Sci. Mater. Med., 1998, 9, 61—65 |

| [20] | Cloing P. G., Zhoung W. G., J. Poly. Sci. A,1991, 24(8), 17360—17365 |

| [1] | WU Yu, LI Xuan, YANG Hengpan, HE Chuanxin. Construction of Cobalt Single Atoms via Double-confinement Strategy for High-performance Electrocatalytic Reduction of Carbon Dioxide [J]. Chem. J. Chinese Universities, 2022, 43(9): 20220343. |

| [2] | TANG Yuanhui, LI Chunyu, LIN Yakai, ZHANG Chunhui, LIU Ze, YU Lixin, WANG Haihui, WANG Xiaolin. Dissipative Particle Dynamics Simulation of the Effect of Polymer Chain Rigidity on Membranes Formation by Nonsolvent Induced Phase Separation Process [J]. Chem. J. Chinese Universities, 2022, 43(10): 20220169. |

| [3] | XIE Fan, CHEN Shanshan, ZHUO Longhai, LU Zhaoqing, GAO Kun, DAI Qiyang. Fabrication of Poly(p-xylene) Nanofiber Arrays by CVD Liquid Crystal Template Method and Their Degradability [J]. Chem. J. Chinese Universities, 2021, 42(8): 2643. |

| [4] | MIAO Weijun, WU Feng, WANG Yong, WANG Zongbao. In⁃situ Study of the Epitaxial Crystallization of PCL/RGO at High Shear Rate [J]. Chem. J. Chinese Universities, 2021, 42(3): 910. |

| [5] | LI Min, ZHAO Chun, FENG Qinzhong, FENG Jian, MENG Xiaojing. Experimental and DFT Studies on the Adsorption of Cd(II) Ions from Aqueous Solutions by Nanofiber Modified Thiourea Groups [J]. Chem. J. Chinese Universities, 2021, 42(12): 3680. |

| [6] | LIN Ningqin, YAO Ke, CHEN Xiangjun. Research Progress of Molecular Recognition and Interaction of Crystallins Linking Cataract [J]. Chem. J. Chinese Universities, 2021, 42(11): 3379. |

| [7] | WANG Mingxia, LIU Zhihui, ZHU Zhen, LI Lingfeng, WANG Bowei. Preparation and Properties of Nano Lithium Magnesium Silicate-chitosan-sodium Alginate Composite Scaffold Materials [J]. Chem. J. Chinese Universities, 2021, 42(10): 3240. |

| [8] | WANG Bowei, MA Rui, WU Fan, LIU Zhihui, LI Lingfeng, ZHANG Xiao, LIU Dingkun, YANG Nan, LI Meihui, YANG Defeng, SUN Qi. Preparation and Characterization of Graphene Oxide-sodium Alginate-chitosan Composite Scaffold [J]. Chem. J. Chinese Universities, 2020, 41(9): 2099. |

| [9] | KONG Jinfeng, ZHU Yuzhang, JIN Jian. Sulfonated Cellulose Nanofibers Film Supported Nanofiltration Membrane for High-flux and High-rejection Desalination † [J]. Chem. J. Chinese Universities, 2020, 41(4): 690. |

| [10] | JI Tianyi, LIU Xiaoxu, ZHAO Jiupeng, LI Yao. Synthesis and Lithium-storage Characteristics of Three-dimensional Cross-linked Graphene Nanofibers † [J]. Chem. J. Chinese Universities, 2020, 41(4): 821. |

| [11] | HAN Zhiying,LI Youji,CHEN Feitai,TANG Senpei,WANG Peng. Preparation of ZnO/Ag2O Nanofibers by Coaxial Electrospinning and Study of Their Photocatalytic Properties † [J]. Chem. J. Chinese Universities, 2020, 41(2): 308. |

| [12] | LIU Guomin, LU Tiancheng, JI Xuan, JIA Wenyuan, LI Yalong, ZHAO Yian, LUO Yungang. Preparation and Osteogenic Induction Activity of CBD-BMP2-MP/PLGA 3D Printed Composite Scaffolds† [J]. Chem. J. Chinese Universities, 2019, 40(7): 1552. |

| [13] | WANG Yongpeng,XU Zibo,LIU Mengzhu,ZHANG Haibo,JIANG Zhenhua. Non-enzymatic Glucose Sensor Based on the Electrospun Porous Foamy Copper Oxides Micro-nanofibers† [J]. Chem. J. Chinese Universities, 2019, 40(6): 1310. |

| [14] | WANG Ruanfeng,YAN Shifeng,HU Zhen,YIN Jingbo. Preparation and Properties of CS/nHA Porous Composite Scaffold Based on In-situ Precipitation Method† [J]. Chem. J. Chinese Universities, 2019, 40(5): 1080. |

| [15] | ZHENG Qiuguang,LIU Hailiang,XIAO Changfa. Preparation and Performance of Poly(vinylidene chloride-co-vinyl chloride) Porous Membranes via Thermally Induced Phase Separation† [J]. Chem. J. Chinese Universities, 2019, 40(4): 841. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||