Chem. J. Chinese Universities ›› 2022, Vol. 43 ›› Issue (2): 20210604.doi: 10.7503/cjcu20210604

• Polymer Chemistry • Previous Articles Next Articles

ZHANG Wenmeng, LI Mengqin, HOU Zhen, CHEN Dongyang( )

)

Received:2021-08-19

Online:2022-02-10

Published:2021-11-10

Contact:

CHEN Dongyang

E-mail:dongyang.chen@fzu.edu.cn

Supported by:CLC Number:

TrendMD:

ZHANG Wenmeng, LI Mengqin, HOU Zhen, CHEN Dongyang. Synthesis and Coating Properties of Carboxylated Fluorinated Poly(arylene ether)s[J]. Chem. J. Chinese Universities, 2022, 43(2): 20210604.

| Sample | Theoretical carboxyl content/(mmol·g-1) | Titrated carboxyl content/(mmol·g-1) | Grafting ratio(%) |

|---|---|---|---|

| CFPAE?1 | 0.076 | 0.069 | 90.79 |

| CFPAE?2 | 0.150 | 0.136 | 90.66 |

| CFPAE?3 | 0.223 | 0.203 | 91.03 |

| CFPAE?4 | 0.294 | 0.265 | 90.14 |

| CFPAE?5 | 0.364 | 0.331 | 90.93 |

| CFPAE?10 | 0.694 | 0.634 | 91.35 |

Table 1 Carboxyl content and grafting ratio of CFPAEs

| Sample | Theoretical carboxyl content/(mmol·g-1) | Titrated carboxyl content/(mmol·g-1) | Grafting ratio(%) |

|---|---|---|---|

| CFPAE?1 | 0.076 | 0.069 | 90.79 |

| CFPAE?2 | 0.150 | 0.136 | 90.66 |

| CFPAE?3 | 0.223 | 0.203 | 91.03 |

| CFPAE?4 | 0.294 | 0.265 | 90.14 |

| CFPAE?5 | 0.364 | 0.331 | 90.93 |

| CFPAE?10 | 0.694 | 0.634 | 91.35 |

| Sample | Thickness/ | Crosshatch adhesion level | Hardness/H | Minimum shaft rod diameter/mm | Maximum falling height of heavy hammer/cm | Gloss/(°) | Contact angle/(°) |

|---|---|---|---|---|---|---|---|

| CFPAE?1 | 43 | 2 | 6 | 0.5 | 80 | 56.3 | 113.6 |

| CFPAE?2 | 44 | 1 | 6 | 0.5 | 70 | 57.4 | 110.6 |

| CFPAE?3 | 44 | 0 | 6 | 0.5 | 60 | 61.6 | 107.3 |

| CFPAE?4 | 43 | 0 | 6 | 0.5 | 50 | 65.5 | 103.9 |

| CFPAE?5 | 45 | 0 | 6 | 0.5 | 40 | 70.9 | 100.1 |

| CFPAE?10 | 46 | 0 | 6 | 0.5 | 20 | 75.8 | 96.7 |

Table 2 Basic properties of CFPAE coatings

| Sample | Thickness/ | Crosshatch adhesion level | Hardness/H | Minimum shaft rod diameter/mm | Maximum falling height of heavy hammer/cm | Gloss/(°) | Contact angle/(°) |

|---|---|---|---|---|---|---|---|

| CFPAE?1 | 43 | 2 | 6 | 0.5 | 80 | 56.3 | 113.6 |

| CFPAE?2 | 44 | 1 | 6 | 0.5 | 70 | 57.4 | 110.6 |

| CFPAE?3 | 44 | 0 | 6 | 0.5 | 60 | 61.6 | 107.3 |

| CFPAE?4 | 43 | 0 | 6 | 0.5 | 50 | 65.5 | 103.9 |

| CFPAE?5 | 45 | 0 | 6 | 0.5 | 40 | 70.9 | 100.1 |

| CFPAE?10 | 46 | 0 | 6 | 0.5 | 20 | 75.8 | 96.7 |

| Sample | Time to get rust/h | Time to form bubble in 5% H2SO4 solution/h | Severity of bubble formation after 3 d in 5% NaOH solution | |

|---|---|---|---|---|

| In H2O | In 3.5% NaCl solution | |||

| Tinplate | 12 | 1 | 1 | None |

| CFPAE?1 | 120 | 7 | 6 | Slight |

| CFPAE?2 | 480 | 22 | 8 | Slight |

| CFPAE?3 | 528 | 36 | 10 | Middle |

| CFPAE?4 | 576 | 40 | 16 | Middle |

| CFPAE?5 | 432 | 32 | 14 | Middle |

| CFPAE?10 | 288 | 24 | 8 | Severe |

Table 3 Chemical resistance properties of CFPAE coatings

| Sample | Time to get rust/h | Time to form bubble in 5% H2SO4 solution/h | Severity of bubble formation after 3 d in 5% NaOH solution | |

|---|---|---|---|---|

| In H2O | In 3.5% NaCl solution | |||

| Tinplate | 12 | 1 | 1 | None |

| CFPAE?1 | 120 | 7 | 6 | Slight |

| CFPAE?2 | 480 | 22 | 8 | Slight |

| CFPAE?3 | 528 | 36 | 10 | Middle |

| CFPAE?4 | 576 | 40 | 16 | Middle |

| CFPAE?5 | 432 | 32 | 14 | Middle |

| CFPAE?10 | 288 | 24 | 8 | Severe |

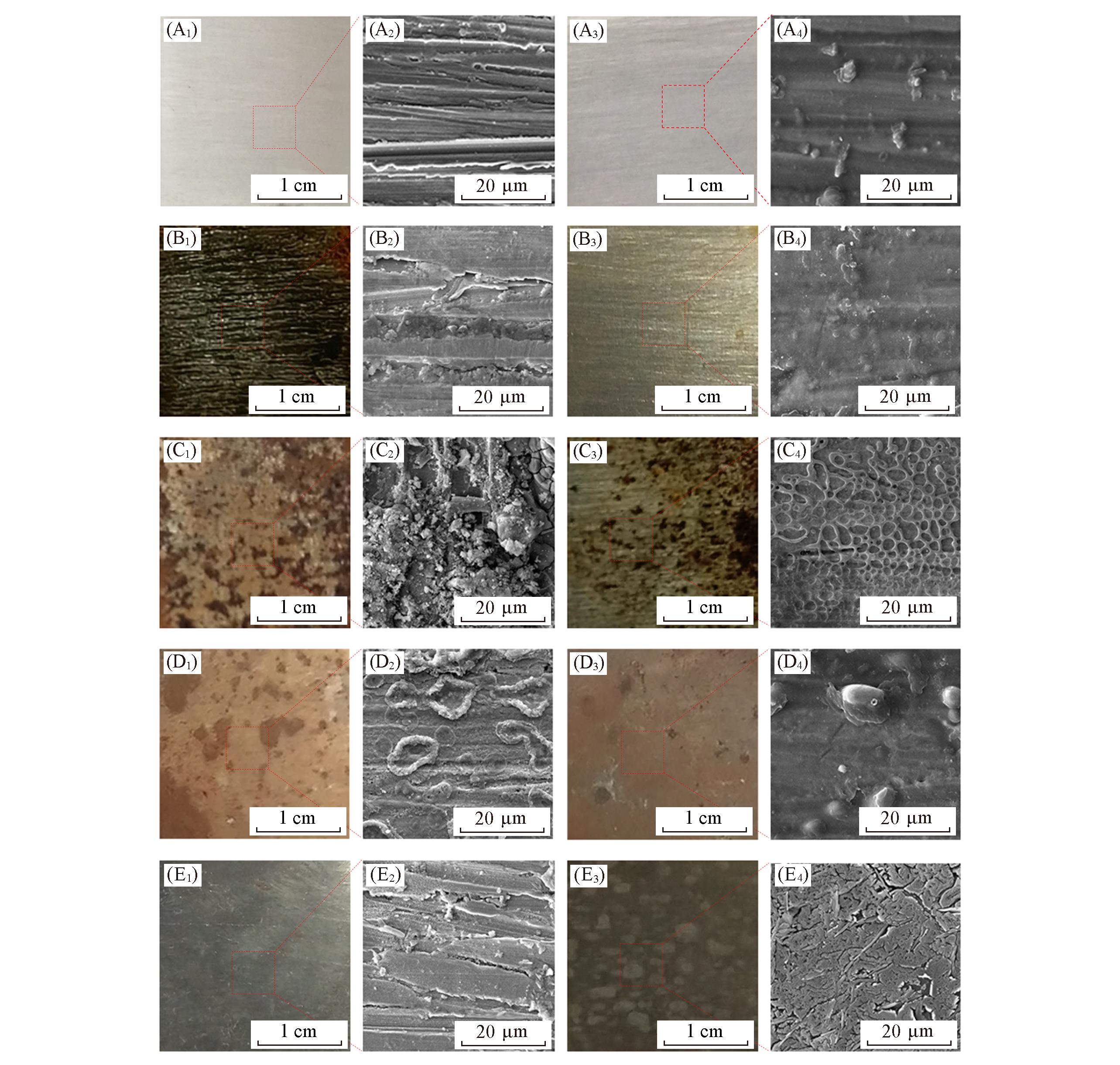

Fig.6 Surface SEM images of the bare tinplate(A1—E1, A2—E2) and CFPAE?4 coated tinplate(A3—E3, A4—E4) before(A1—A4) and after(B1—E1, B2—E2, B3—E3, B4—E4) immersed in different solutions with different time(B1—B4) H2O, 30 d; (C1—C4) 3.5% NaCl solution, 3d; (D1—D4) 5% H2SO4, 36 h; (E1—E4) 5% NaOH solution, 3 d.

| Sample | Crosshatch adhesion | Hardness/H | Minimum shaft rod diameter/ mm | Gloss/(°) | Water contact angle(°) |

|---|---|---|---|---|---|

| CFPAE?1 | 1 | 6 | 0.5 | 37.5 | 80.52 |

| CFPAE?2 | 0 | 6 | 0.5 | 36.0 | 77.90 |

| CFPAE?3 | 0 | 6 | 0.5 | 35.6 | 74.22 |

| CFPAE?4 | 0 | 6 | 0.5 | 35.5 | 71.77 |

| CFPAE?5 | 0 | 6 | 0.5 | 34.5 | 69.70 |

| CFPAE?10 | 0 | 6 | 0.5 | 32.8 | 65.85 |

Table 4 Properties of CFPAE coatings after 720 h of UV?light aging

| Sample | Crosshatch adhesion | Hardness/H | Minimum shaft rod diameter/ mm | Gloss/(°) | Water contact angle(°) |

|---|---|---|---|---|---|

| CFPAE?1 | 1 | 6 | 0.5 | 37.5 | 80.52 |

| CFPAE?2 | 0 | 6 | 0.5 | 36.0 | 77.90 |

| CFPAE?3 | 0 | 6 | 0.5 | 35.6 | 74.22 |

| CFPAE?4 | 0 | 6 | 0.5 | 35.5 | 71.77 |

| CFPAE?5 | 0 | 6 | 0.5 | 34.5 | 69.70 |

| CFPAE?10 | 0 | 6 | 0.5 | 32.8 | 65.85 |

| Sample | Ecorr/V | Icorr/(A·cm-2) | Ic/(mm·year-1) | Sample | Ecorr/V | Icorr/(A·cm-2) | Ic/(mm·year-1) |

|---|---|---|---|---|---|---|---|

| Tinplate | -0.677 | 1.804×10-5 | 2.111×10-1 | CFPAE?4 | -0.416 | 5.177×10-8 | 9.163×10-4 |

| CFPAE?1 | -0.360 | 3.788×10-8 | 6.705×10-4 | CFPAE?5 | -0.428 | 5.319×10-8 | 9.415×10-4 |

| CFPAE?2 | -0.402 | 1.873×10-8 | 3.315×10-4 | CFPAE?10 | -0.486 | 1.877×10-7 | 3.322×10-3 |

| CFPAE?3 | -0.401 | 4.891×10-8 | 8.657×10-4 |

Table 5 Ecorr, Icorr and Ic of tinplate and CFPAE coated tinplates

| Sample | Ecorr/V | Icorr/(A·cm-2) | Ic/(mm·year-1) | Sample | Ecorr/V | Icorr/(A·cm-2) | Ic/(mm·year-1) |

|---|---|---|---|---|---|---|---|

| Tinplate | -0.677 | 1.804×10-5 | 2.111×10-1 | CFPAE?4 | -0.416 | 5.177×10-8 | 9.163×10-4 |

| CFPAE?1 | -0.360 | 3.788×10-8 | 6.705×10-4 | CFPAE?5 | -0.428 | 5.319×10-8 | 9.415×10-4 |

| CFPAE?2 | -0.402 | 1.873×10-8 | 3.315×10-4 | CFPAE?10 | -0.486 | 1.877×10-7 | 3.322×10-3 |

| CFPAE?3 | -0.401 | 4.891×10-8 | 8.657×10-4 |

| 1 | Hua M., Yong Y., Tong L., Wei R., Liu X., J. Mater. Sci., 2018, 29(4), 3127—3134 |

| 2 | Raja R. R. S., Rashmi W., Khalid M., Wong W. Y., Priyanka J., Polymers, 2020, 12(5), 1061 |

| 3 | Wang P., Jia K., Zhou X., Guan X., Wang L., Tian Y., Wu C., Liu X., Macromol. Rapid Comm., 2017, 38(21), 1700360—1700365 |

| 4 | Chen X., Lü H., Lin Q., Zhang X., Chen D., Zheng Y., J. Membr. Sci., 2018, 549, 12—22 |

| 5 | Liu D., Lin L., Xie Y., Pang J., Jiang Z., J. Membr. Sci., 2021, 623, 119079—119086 |

| 6 | Zhan Y. Q., Wan X. Y., He S. J., Yang Q. B., He Y., Chem. Eng. J.,2017, 333, 142—145 |

| 7 | Banerjee S., Maier G., Chem. Mater., 1999, 11(8), 2179—2184 |

| 8 | Dong Q., Fu Y., Wang H., Bai R., Langmuir, 2020, 36(42), 12513—12520 |

| 9 | Hu W., Liu B. J., Zhang L. M., Zhang S. L., Jiang Z. H., Wang G. B., Wu Z. W., Chem. J. Chinese Universites,2003, 24(1), 184—185(呼微, 刘佰军, 张丽梅, 张淑玲, 姜振华, 王贵宾, 吴忠文. 高等学校化学学报, 2003, 24(1), 184—185) |

| 10 | Hu W., Liu B. J., Wang D., Ma X. Y., Rao X. H., Li T., Jiang Z. H., Wu Z. W., Chem.J. Chinese Universities,2003, 24(8), 1522—1524(呼微, 刘佰军, 王冬, 马小野, 饶先花, 李婷, 姜振华, 吴忠文. 高等学校化学学报, 2003, 24(8), 1522—1524) |

| 11 | Irvin J. A., Neef C. J., Kane K. M., Cassidy P. E., Clair A. K. S., J. Polym. Sci. Pol. Chem.,1992, 30(8), 1675—1679 |

| 12 | Tkachenko I. M., Kobzar Y. L., Yakovlev Y. V., Shekera O. V., Klepoko V. V., Macromol. Res., 2017, 25(2), 112—119 |

| 13 | Xia J., Pu Z., Zheng X., Hu L., Zhong J., J. Polym. Res., 2020, 27(9), 289—297 |

| 14 | Lee L. H., J. Adhesion., 1994, 46(1—4), 15—38 |

| 15 | Guo H. J., Wang X., Zong L. S., Li J. F., Wang J. Y., Li G. Y.,Jian X. G., Acta Polym. Sin., 2018,(9), 1236—1243(郭鸿俊, 王雪, 宗立率, 李建芳, 王锦艳, 李桂洋, 蹇锡高. 高分子学报, 2018,(9), 1236—1243) |

| 16 | Zhang Y., Yan H., Pan G. Y., Guo M., Liu T. Q., Petrochemical Technology, 2013, 42(6), 661—665(张杨, 严昊, 潘国元, 郭敏, 刘轶群. 石油化工, 2013, 42(6), 661—665) |

| 17 | Liu Z. B., Hu Q., Lu J. H., Long S. L., Yan G. M., Zhang G., Chem. Res. Appl.,2018, 30(9), 1481—1486(刘资备, 胡全, 卢杰宏, 龙盛如, 严光明, 张刚. 化学研究与应用, 2018, 30(9), 1481—1486) |

| 18 | Liu D., Wang Z. G., Acta. Polym. Sin.,2010,(5), 567—573(刘丹, 王忠刚. 高分子学报, 2010,(5), 567—573) |

| 19 | Zhou L., Zhu J., Lin M., Xu J., Xie Z., Chen D., J. Energy. Chem.,2020, 40, 57—64 |

| 20 | Chen X. L., Lv H. X., Lin Q. L, Zhang X., Chen D. Y., Zheng Y. Y., J. Membr. Sci., 2018, 549, 12—22 |

| 21 | Han J. H., Cui Y. Y., He X. Q., Zhang Y., Yang C. X., J. Chromatogr. A,2021, 1640, 461947—461956 |

| 22 | Giulia G., Ganzerla R., Bortoluzzi M., Paganicaet R., Prog. Org. Coat., 2016, 101, 90—99 |

| 23 | Geng S., Guo J., Li X. G.,Zhao Q. L., J. Univ. Sci. Technol. B.,2009, 31(6), 752—757(耿舒, 高瑾, 李晓刚, 赵泉林. 北京科技大学学报, 2009, 31(6), 752—757) |

| 24 | Brockmann H., J. Adhesion,1987, 22(2), 71—76 |

| 25 | Huang H., Guo H., Feng Y., Mater. Res. Express,2020, 8, 015301 |

| 26 | Jie H., Xu Q., Wei L., Min Y. L., Corros. Sci.,2016, 102, 251—258 |

| 27 | Xia Z., Liu G., Dong Y., Zhang Y., Prog. Org. Coat.,2019, 133, 154—160 |

| 28 | Ai Y. F., Xia L., Pang F. Q., Xu Y. L., Zhao H. B., Jian R. K., Compos. Part B Eng., 2020, 193(15), 108019 |

| [1] | ZHANG Zhen, DENG Yu, ZHANG Qinfang, YU Dagang. Visible Light-driven Carboxylation with CO2 [J]. Chem. J. Chinese Universities, 2022, 43(7): 20220255. |

| [2] | JIANG Hongbin, DAI Wenchen, ZHANG Rao, XU Xiaochen, CHEN Jie, YANG Guang, YANG Fenglin. Research on Co3O4/UiO-66@α-Al2O3 Ceramic Membrane Separation and Catalytic Spraying Industry VOCs Waste Gas [J]. Chem. J. Chinese Universities, 2022, 43(6): 20220025. |

| [3] | ZHANG Taiwen, GUO Jun, ZHANG Dan, YUAN Changmei, QIU Shuangyan. Synthesis, Characterization and Catalytic Oxidation Iodine Ion Performance of trz-Cl-Cu-PMo12 [J]. Chem. J. Chinese Universities, 2022, 43(10): 20220215. |

| [4] | ZHU Shiyang, ZHANG Yunhe, LI Qingwei, JI Fangang, GUAN Shaowei. Mechanical and Tribological Properties of PEEK Coatings with Different Melt Indexes Prepared by Electrostatic Powder Spray Technique† [J]. Chem. J. Chinese Universities, 2014, 35(5): 1075. |

| [5] | ZHANG Kai, WU La-Xia, HU Lei-Lei, DING Xiao-Yan, WANG Huan*, LU Jia-Xing*. Electrosynthesis of 2-Hydroxy-2-(4-methoxy-phenyl)-propionic Acid Methyl Ester via Electrochemical Fixation of Carbon Dioxide [J]. Chem. J. Chinese Universities, 2010, 31(7): 1410. |

| [6] | YANG Yan-Lian, ZHANG Jin, NAN Xiao-Lin, LIU Zhong-Fan . Studies on the Dissociation Behavior of Carboxylic Groups at the Open End of Single-Walled Carbon Nanotubes by Tip Chemistry [J]. Chem. J. Chinese Universities, 2002, 23(3): 469. |

| [7] | FU Qiang, ZHANG Hua, HE Hui-Xin, LIU Zhong-Fan . Force Titration of ω-Mercapto-n-undecylamine Self-assembled Monolayers by Chemical Force Microscopy [J]. Chem. J. Chinese Universities, 2000, 21(11): 1738. |

| [8] | ZHENG Guo-Dong, YAN Yan, GAO Sai, TONG Shan-Ling, GAO De. Electrocarboxylation of Organic Compounds with Carbon Dioxide Catalyzed by Metalloporphyrins(Ⅴ)─Electrocarboxylation of Halobutane with CO2 Catalyzed by CoTPP and VB12 [J]. Chem. J. Chinese Universities, 1994, 15(7): 956. |

| [9] | WANG Mei, Pan Xin, LIU Jin-Xiang, GAO Xiu-Ying. A Study on Temporarily Water-soluble Disperse Dyes Containing Carboxymethylsulfonyl Group ──The Kinetics of Decarboxylation of Intermediates and Dyes [J]. Chem. J. Chinese Universities, 1994, 15(5): 741. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||