Chem. J. Chinese Universities ›› 2019, Vol. 40 ›› Issue (11): 2332.doi: 10.7503/cjcu20190309

• Physical Chemistry • Previous Articles Next Articles

WU Wei1,LIU Yuchun1,ZHU Guancun1,AN Jiayu1,DOU Guangpeng1,WANG Yuyan1,LIU Jing1,*( ),SUN Donglan2,*(

),SUN Donglan2,*( ),GUO Yeping3

),GUO Yeping3

Received:2019-05-30

Online:2019-11-10

Published:2019-08-20

Contact:

LIU Jing,SUN Donglan

E-mail:jingliu@tust.edu.cn;sundonglan@tust.edu.cn

Supported by:CLC Number:

TrendMD:

WU Wei, LIU Yuchun, ZHU Guancun, AN Jiayu, DOU Guangpeng, WANG Yuyan, LIU Jing, SUN Donglan, GUO Yeping. Application of Polyethylene Separator Modified by Methyl Acrylic Polymer in Lithium Ion Battery †[J]. Chem. J. Chinese Universities, 2019, 40(11): 2332.

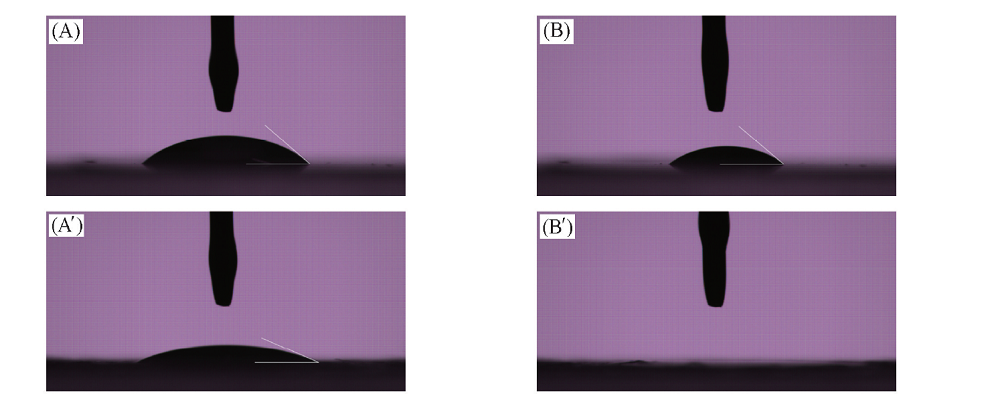

Fig.2 Photographs of static contact angle of 1 mol/L LiPF6 in EC+DMC(volume ratio 1:1) liquid electrolyte on uncoated separator initial(A) and after 15 min(B) and on coated separator initial(A') and after 20 s(B'), respectively

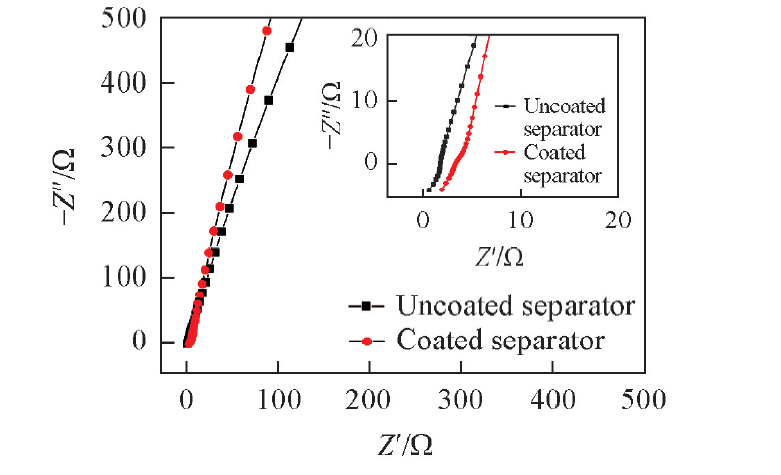

Fig.5 Alternating current impedance curve of uncoated and coated separator at room temperature SS/separator/SS cells, frequency range 1.0 MHz — 0.01 Hz, amplitude 10 mV.

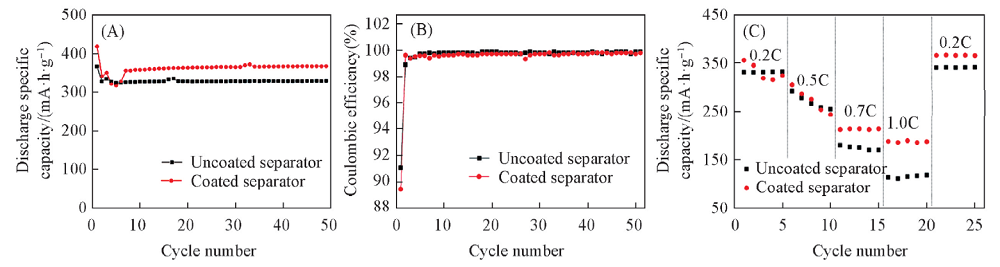

Fig.6 Discharge specific capacity(A) and coulombic efficiency(B) of the Li/MCMB cells with uncoated or coated separator under 0.2C rate between the voltage ranges of 0.005—1.5 V at room temperature for 50 cycles and discharge specific capacity of Li/MCMB cells with uncoated or coated separator at various rates cycling(C)

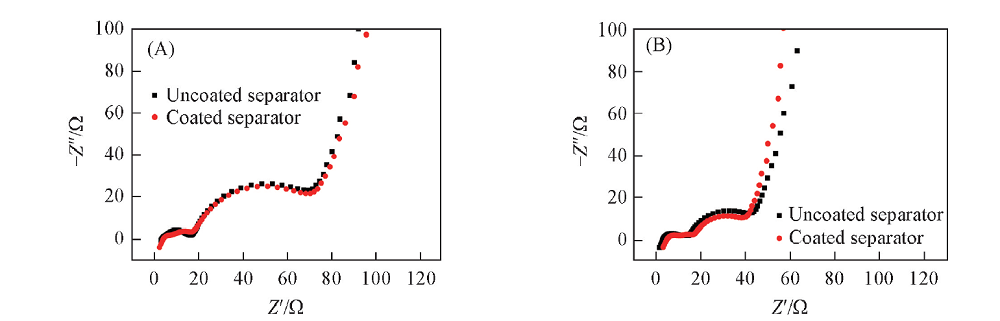

Fig.7 Alternating current impedance curves of the Li/MCMB cells with the uncoated and coated separators after 2 cycles(A) and after 20 cycles(B) Frequency range: 1.0 MHz—0.01 Hz, amplitude 10 mV.

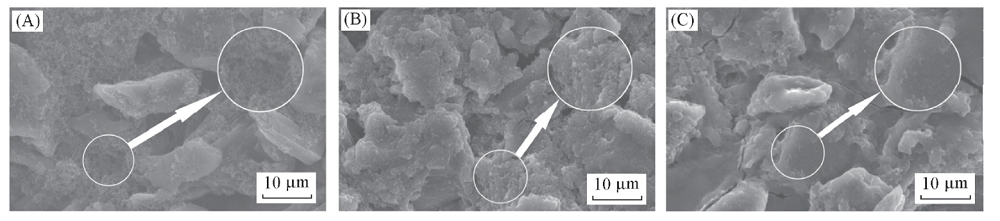

Fig.8 SEM images of MCMB electrodes (A) Fresh MCMB electrode; (B) MCMB electrode of Li/MCMB cell with uncoated separator after 50 cycles; (C) MCMB electrode of Li/MCMB cell with coated separator after 50 cycles. Acceleration voltage: 20 kV.

| [50] | Xie H. L., Liao Y. H., Sun P., Chen T. T., Rao M. M., Li W. S., Electrochimica Acta, 2014,127(1), 327— 333 |

| [51] | Verma P., Maire P., Novák P ., Electrochimica Acta, 2010,55(22), 6332— 6341 |

| [52] | Röser S., Lerchen A., Ibing L., Cao X., Kasnatscheew J., Glorius F., Winter M., Wagner R ., Chemistry of Materials, 2017,29(18), 7733— 7739 |

| [53] | Zhao H., Zhou X., Park S. J., Shi F. F., Fu Y. B., Ling M., Yucn N., Battagliaa V., Liu G., Journal of Power Sources, 2014,263(1), 288— 295 |

| [54] | Winter M., Barnett B., Xu K ., Chemical Reviews, 2018,118(23), 11433— 11456 |

| [55] | Zhang S. S., Journal of Power Sources, 2007,163(2), 713— 718 |

| [56] | Chen R. J., Zhu L., Wu F., Li L., Zhang R., Chen S., Journal of Power Sources, 2014,245(1), 730— 738 |

| [57] | Zhang S. S., Xu K., Jow T. R., Electrochimica Acta, 2004,49(7), 1057— 1061 |

| [58] | Xu Q., Kong Q. S., Liu Z. H., Zhang J. J., Wang X. J., Liu R. Z., Yue L. P., Cui G. L., RSC Advances, 2014,4(16), 7845— 7850 |

| [59] | Prasanna K., Subburaj T., Lee W. J., Lee C. W., Electrochimica Acta, 2014,137(10), 273— 279 |

| [60] | Yi J., Tan C. L., Li W. S., Liao Y. H., Rao M. M., Journal of South China Normal University(Natural Science Edition), 2009, ( S1), 228— 232 |

| ( 易金, 谭春林, 李伟善, 廖友好, 饶睦敏 . 华南师范大学学报(自然科学版), 2009, ( S1), 228— 232) | |

| [1] | Lu L. G., Han X. B., Li J. Q., Hua J. F., Ouyang M. G., Journal of Power Sources, 2013,226(3), 272— 288 |

| [2] | Marom R., Amalraj S. F., Leifer N., Jacob, D., Aurbach D., Journal of Materials Chemistry, 2011,21(27), 9938— 9954 |

| [3] | Li Z., Cao T. T., Zhang Y., Han Y., Xu S. M., Xu Z. H., Journal of Membrane Science, 2017,540(17), 422— 429 |

| [4] | Zhang J. Q., Sun B., Huang X. D., Chen S. Q., Wang G. X., Scientific Reports, 2014,4, 6007 |

| [5] | Xiang Y. Y., Zhu W. Y., Qiu W. J., Guo W., Lei J. H., Liu D., Qu D. Y., Xie Z. Z., Tang H. L., Li J. S., Chemistry Select, 2018,3(3), 911— 916 |

| [6] | Zhang J.J., Yue L. P., Kong Q. S., Liu Z. H., Zhou X. H., Zhang C. J., Xu Q., Zhang B., Ding G. L., Qin B. S., Duan Y. L., Wang Q. F., Yao J. H., Cui G. L., Chen L. Q., Scientific Reports, 2014,4, 3935 |

| [7] | Huang X., Hitt J., Journal of Membrane Science, 2013,425/426(1), 163— 168 |

| [8] | Croce F., Focarete M. L., Hassoun J., Meschini I., Scrosati B., Energy & Environmental Science, 2011,4(3), 921— 927 |

| [9] | Cho T.H., Tanaka M., Ohnishi H., Kondo Y., Yoshikazu M., Nakamura T., Sakai T., Journal of Power Sources, 2010,195(13), 4272— 4277 |

| [10] | Zhang L., Xiong Y., Sun S. P., Zhang L., Li S. S., Liu X. G., Xu Z. H., Xu S. M., Journal of Membrane Science, 2018,565(1), 50— 60 |

| [11] | Xu W. X., Wang Z. Y., Shi L. Y., Ma Y., Yuan S., Sun L. N., Zhao Y., Zhang M. H., Zhu J. F., ACS Applied Materials Interfaces, 2015,7(37), 20678— 20686 |

| [12] | Kim K. J., Kim J. H., Park M. S., Kwon H. K., Kim H., Kim Y. J., Journal of Power Sources, 2012,198(15), 298— 302 |

| [13] | Choi J.A., Kim S. H., Kim D. W., Journal of Power Sources, 2010,195(18), 6192— 6196 |

| [14] | Shi J. L., Xia Y. G., Yuan Z. Z., Hu H. S., Li X. F., Zhang H. M., Liu Z. P., Scientific Reports, 2015,5, 8255 |

| [15] | Chen W. J., Shi L. Y., Wang Z. Y., Zhu J. F., Yang H. J., Mao X. F., Chi M. M., Sun L. N., Yuan S., Carbohydrate Polymers, 2016,147(20), 517— 524 |

| [16] | Lee Y. J., Lee H., Lee T., Ryou M. H., Lee Y. M., Journal of Power Sources, 2015,294(30), 537— 544 |

| [17] | Man C. Z., Jiang P., Wong K. W., Zhao Y., Tang C. Y., Fan M. K., Lau W. M., Mei J., Li S. M., Liu H., Hui D., Journal of Materials Chemistry A, 2014,2(30), 11980— 11986 |

| [18] | Osada I., Vries H. D., Scrosati B., Passerini S., Angewandte Chemie International Edition, 2016,55(2), 500— 513 |

| [19] | Park M. J., Choi I., Hong J., Kim O., . Journal of Applied Polymer Science, 2013,129(5), 2363— 2376 |

| [20] | Kalhoff J. L., Eshetu G. G., Bresser D., Passerini S., ChemSusChem, 2015,8(17), 2154— 2175 |

| [21] | Tan S., Ji Y. J., Zhang Z. R., Yang Y., ChemPhysChem, 2014,15(10), 1956— 1969 |

| [22] | Li J., Lin Y., Yao H. H., Yuan C. F., Liu J., ChemSusChem, 2014,7(7), 1901— 1908 |

| [23] | Liang S. W., Choi U. H., Liu W. J., Runt J., Colby R. H., Chemistry of Materials, 2012,24(12), 2316— 2323 |

| [24] | Zhang Z. C., Lyons L. J., West R., Amine K., West R., Silicon Chemistry, 2007,3(5), 259— 266 |

| [25] | Tillmann S. D., Isken P., Lexbalducci A., Journal of Physical Chemistry C, 2015,119(27), 14873— 14878 |

| [26] | Matsumoto K., Kakehashi M., Ouchi H., Yuasa M., Endo T ., Macromolecules, 2016,49(24), 9441— 9448 |

| [27] | Jana S., Parthiban A., Chai C. L. L., Chemical Communications, 2010,46(9), 1488— 1490 |

| [28] | Chen T. T., Liao Y. H., Wang X. S., Luo X. Y., Li X. P., Li W. S., Electrochimica Acta, 2016,191(10), 923— 932 |

| [29] | Chai J. C., Liu Z. H., Ma J., Wang J., Liu X. C., Liu H. S., Zhang J. J., Cui J. L., Chen L. Q., Journal of Electroanalytical Chemistry, 2017,804(2), 133— 139 |

| [30] | Zhang Z. Q., Li H., Lv X. Y., Liu H. Z., Theng L. X., Advanced Materials Research, 2012,463/464, 1378— 1381 |

| [31] | Shi J. L., Fang L. F., Li H., Zhang H., Zhu B. K., Zhu L. P., Journal of Membrane Science, 2013,437, 160— 168 |

| [32] | Lu X., Wang B ., China Synthetic Fiber Industry, 2017,40(2), 22— 27 |

| ( 陆茜, 王彪 . 合成纤维工业, 2017,40(2), 22— 27) | |

| [33] | Li R. J., Liu J., Tao H. R., Sun D. L., Xiao D. G., Liu C. J., Thermochimica Acta, 2016,624(20), 76— 81 |

| [34] | Camara F., Caillol S., Boutevin B ., European Polymer Journal, 2014,61(1), 133— 144 |

| [35] | Guo M. Y., Zong C. X., Ai S. J., Fu F. Z., Wang Q., Liu J., Sun D. L., Guo Y. L., Guo Y. P., Chem. J. Chinese Universities, 2017,38(10), 1857— 1863 |

| ( 郭梦雅, 宗成星, 艾淑娟, 付凤至, 王琪, 刘靖, 孙冬兰, 郭艳玲, 郭也平 . 高等学校化学学报, 2017,38(10), 1857— 1863) | |

| [36] | Ali U., Karim K. J. B. A., Buang N. A., Polymer Reviews, 2015,55(4), 1— 28 |

| [37] | Fan L., Wei S. Y., Li S. Y., Li Q., Lu Y. Y., Advanced Energy Materials, 2018,8(11), 1— 22 |

| [38] | Chen X. L., Pan J., Zhao Y., Liao M., Peng H. S., Advanced Energy Materials, 2017,8(7), 1— 16 |

| [39] | Sun P., Liao Y. H., Xie H. I., Chen T. T., Rao M. M., Li W. S., Journal of Power Sources, 2014,269(10), 299— 307 |

| [40] | Liu J., Li R. J., Guo M. Y., Tao H. R., Sun D. L., Zong C. X., Liu C. J., Fu F. Z., Thermochimica Acta, 2017,654(10), 179— 185 |

| [41] | Ahmad Z., Al-Awadi N. A., Al-Sagheer F., Polymer Degradation and Stability, 2008,93(2), 456— 465 |

| [42] | Beyler C. L., Hirschler M. M., . Thermal Decomposition of Polymers, SFPE Handbook of Fire Protection Engineering, 3rd Ed., Springer, New York, 2001, 110— 131 |

| [43] | Huang P. F., . Research on the Fire Risk of Lithium Ion Battery and the Critical Condition of Thermal Runaway Behavior , University of Science and Technology of China, Hefei, 2018 |

| ( 黄沛丰 . 锂离子电池火灾危险性及热失控临界条件研究, 合肥: 中国科学技术大学, 2018) | |

| [44] | Wang D., Zhao Z. L., Yu L. N., Zhang K. J., Na H., Ying S. Q., Xu D. C., Zhang G., Journal of Applied Polymer Science, 2014,131(15), 4401— 4404 |

| [45] | Britz J., Meyer W. H., Wegner G., Macromolecules, 2007,40(21), 7558— 7565 |

| [46] | Ye W., Zhu J., Liao X.J., Jiang S. H., Li Y. H., Fang H., Hou H. Q., Journal of Power Sources, 2015,299(20), 417— 424 |

| [47] | Huang X. S., Journal of Solid State Electrochemistry, 2011,15(4), 649— 662 |

| [48] | Ma T., Cui Z. Y., Wu Y., Qin S. H., Wang H., Yan F., Han N., Li J. X., Journal of Membrane Science, 2013,444(10), 213— 222 |

| [49] | Suharto Y., Lee Y., Yu J. S., Choi W. C., Kim K. J., Journal of Power Sources, 2018,376(1), 184— 190 |

| [1] | LI Huiyang, ZHU Siying, LI Sha, ZHANG Qiaobao, ZHAO Jinbao, ZHANG Li. Influencing Factors and Promotion Strategies of the First-cycle Coulombic Efficiency of Silicon Suboxide Anodes in Lithium-ion Batteries [J]. Chem. J. Chinese Universities, 2021, 42(8): 2342. |

| [2] | LIU Tiefeng, ZHANG Ben, SHENG Ouwei, NAI Jianwei, WANG Yao, LIU Yujing, TAO Xinyong. Research Progress of the Binders for the Silicon Anode [J]. Chem. J. Chinese Universities, 2021, 42(5): 1446. |

| [3] | LI Shuhui, HUANG Jianying, LAI Yuekun. Advanced Progress of Green Textile with Special Wettability [J]. Chem. J. Chinese Universities, 2021, 42(4): 1043. |

| [4] | WANG Renheng, XIAO Zhe, LI Yan, SUN Yiling, FAN Shuting, ZHENG Junchao, QIAN Zhengfang, HE Zhenjiang. Synthesis of Li2FeP2O7 Cathode Material at Different Temperatures and Its Electrochemical Performance for Lithium Ion Batteries [J]. Chem. J. Chinese Universities, 2021, 42(4): 1299. |

| [5] | HAN Muyao, ZHAO Lina, SUN Jie. Advances in Silicon and Silicon-based Anode Materials [J]. Chem. J. Chinese Universities, 2021, 42(12): 3547. |

| [6] | ZHANG Jiayi, DING Zhenyao, WANG Dandan, CHEN Liping, FENG Xinjian. Fabrication of Triphase Enzyme Electrode Based on Porous Gold Substrate for High-performance Electrochemical Biosensor [J]. Chem. J. Chinese Universities, 2021, 42(10): 3167. |

| [7] | JIANG Huayi,LIU Mei,QI Hongyuan,LIANG Aiguo,WANG Yulong,SUN Nana,WU Zhe. Fractal Characteristics of the Microstructures of Three Hydrophobic Surfaces with Steel Substrate and Their Effects on Wettability † [J]. Chem. J. Chinese Universities, 2020, 41(6): 1313. |

| [8] | ZHANG Chenyang,WEN Yuehua,ZHAO Pengcheng,CHENG Jie,QIU Jingyi,SUN Yanzhi. Effect of Organic Carbon Source on Performance of LiTi2(PO4)3/C Composite Electrodes in Aqueous Solutions † [J]. Chem. J. Chinese Universities, 2020, 41(6): 1352. |

| [9] | JI Tianyi, LIU Xiaoxu, ZHAO Jiupeng, LI Yao. Synthesis and Lithium-storage Characteristics of Three-dimensional Cross-linked Graphene Nanofibers † [J]. Chem. J. Chinese Universities, 2020, 41(4): 821. |

| [10] | DAI Haoyu,DONG Zhichao,JIANG Lei. Research Advance of Electrically Controlled Droplet Motion † [J]. Chem. J. Chinese Universities, 2020, 41(1): 1. |

| [11] | FANG Liang,DING Xiaoli,SONG Yun,LIU Dongming,LI Yongtao,ZHANG Qingan. Effect of Morphological Tuning on Electrochemical Performance of Perovskite LaCoO3 Anodes† [J]. Chem. J. Chinese Universities, 2019, 40(7): 1456. |

| [12] | LIN Yucai,PEI Wenle,SUN Ruoxuan,GAO Chunlei,CHEN Jipeng,ZHENG Yongmei. Droplet Condensation on Surfaces with Special Wettability† [J]. Chem. J. Chinese Universities, 2019, 40(6): 1236. |

| [13] | Yuzhen DUAN,Jinyu ZHU,Junming GUO,Mingwu XIANG,Xiaofang LIU,Hongli BAI,Changwei SU. Synthesis and Electrochemical Properties of Spinel Lithium Manganese Cathode Material LiNi0.01Co0.03Mn1.96O4 † [J]. Chem. J. Chinese Universities, 2019, 40(12): 2574. |

| [14] | LI Xiangnan,YU Mingming,FAN Yong,WANG Qiuxian,ZHANG Huishuang,YANG Shuting. Study on Electrochemical Performances of N-doped P/C Composite as Anode Material of Lithium Ion Batteries † [J]. Chem. J. Chinese Universities, 2019, 40(11): 2360. |

| [15] | LI Yi, LI Chun, YU Kaifeng. Preparation, Characterization and Electrochemical Properties of Mesoporous Biomass Carbon Derived from Corn Stalk† [J]. Chem. J. Chinese Universities, 2018, 39(4): 607. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||