Chem. J. Chinese Universities ›› 2017, Vol. 38 ›› Issue (7): 1286.doi: 10.7503/cjcu20160831

• Polymer Chemistry • Previous Articles Next Articles

LI Caixin, LIANG Xiaorong, GU Ju*( )

)

Received:2016-11-24

Online:2017-07-10

Published:2017-04-18

Contact:

GU Ju

E-mail:psjgu@scut.edu.cn

TrendMD:

LI Caixin, LIANG Xiaorong, GU Ju. Preparation and Characterization of Bagasse Nanocellulose†[J]. Chem. J. Chinese Universities, 2017, 38(7): 1286.

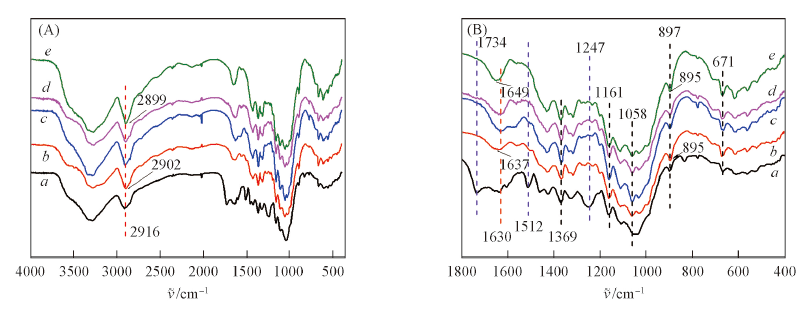

Fig.1 FTIR spectra of raw bagasse(a), BNC-1(b), BNC-2(c), BNC-3(d) and BNC-S(e) (A) Wavenumber ranges of 4000—400 cm-1; (B) wavenumber ranges of 1800—400 cm-1.

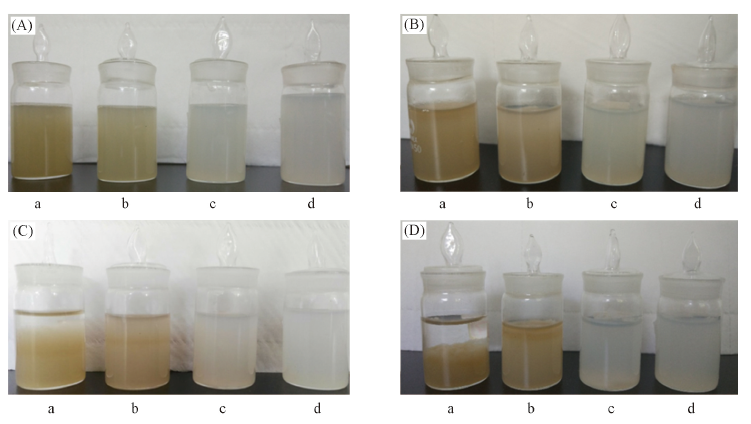

Fig.4 Photographs of BNC-1(a), BNC-2(b), BNC-3(c) and BNC-S(d) water suspension with low concentrations quiescence in room temperature with 1 d(A), 5 d(B), 15 d(C) and 30 d(D)

| Sample | Onset decomposition temperature/℃ | Temperature of maximum mass loss rate/℃ | Char yield(%) |

|---|---|---|---|

| Bagasse | 310.9 | 364.8 | 25.4 |

| BNC-1 | 305.8 | 354.8 | 23.5 |

| BNC-2 | 304.2 | 352.3 | 26.0 |

| BNC-3 | 296.6 | 344.8 | 26.5 |

| BNC-S | 295.0 | 339.8 | 28.0 |

Table 1 TGA and DTG parameters of raw bagasse materials and the extracted BNC

| Sample | Onset decomposition temperature/℃ | Temperature of maximum mass loss rate/℃ | Char yield(%) |

|---|---|---|---|

| Bagasse | 310.9 | 364.8 | 25.4 |

| BNC-1 | 305.8 | 354.8 | 23.5 |

| BNC-2 | 304.2 | 352.3 | 26.0 |

| BNC-3 | 296.6 | 344.8 | 26.5 |

| BNC-S | 295.0 | 339.8 | 28.0 |

| [1] | Tang L. L., Huang B., Dai D. S., Ou W., Lin Y. P., Chen X. L., Spectrosc. Spect. Anal., 2010, 30(7), 1876—1879 |

| (唐丽荣, 黄彪, 戴达松, 欧文, 林炎平, 陈学榕.光谱学与光谱分析, 2010, 30(7), 1876—1879) | |

| [2] | Favier V., Chanzy H., Cavaille J. Y., Macromolecules,1995, 28(18), 6365—6367 |

| [3] | Azizi Samir M. A., Alloin F., Dufresne A., Biomacromolecules,2005, 6(2), 612—626 |

| [4] | Julien B., Mohammad L. H., Cecile B., Enas A. H., Nahla A. E., Alain D., Ind. Crop. Prod., 2010, 32(3), 627—633 |

| [5] | Šturcová A, Davies G. R., Eichhom S. J., Biomacromolecules,2005, 6(2), 1055—1061 |

| [6] | And M. N. A., Dufresne A., Macromolecules,2000, 33(22), 8344—8353 |

| [7] | And A. D., Vignon M. R., Macromolecules,1998, 31(31), 2693—2696 |

| [8] | Ljungberg N., Bonini C., Bortolussi F., Boisson C., Heux L., Biomacromolecules,2005, 6(6), 2732—2739 |

| [9] | Cao X., Dong H., Li C. M., Biomacromolecules,2007, 8(3), 899—904 |

| [10] | Chauve G., Heux L., Arouini R., Mazeau K., Biomacromolecules,2005, 6(4), 2025—2031 |

| [11] | Samir M. A. S. A., Alloin F., Sanchez J. Y., Dufresne A., Macromolecules,2004, 37(13), 4839—4844 |

| [12] | Samir M. A. S. A., Alloin F., Gorecki W., Sanchez J. Y., Dufresne A., J. Phys. Chem.B,2004, 108(30), 10845—10852 |

| [13] | Yang Z. Y., Wang W. J., Shao Z. Q., Li Y. H., Chem. J. Chinese Universities,2013, 34(4), 1021—1026 |

| (杨振钰, 王文俊, 邵自强, 李永红.高等学校化学学报, 2013, 34(4), 1021—1026) | |

| [14] | Bai L., Zhang L. P., Qu P., Gao Y., Qin Z., Sun S. Q., Chem. J. Chinese.Universities,2011, 32(4), 984—989 |

| (白露, 张力平, 曲萍, 高源, 秦竹, 孙素琴.高等学校化学学报, 2011, 32(4), 984—989) | |

| [15] | Tang L. L., Huang B., Dai D. S., Ou W., Li Y. H., Chen X. L., Sci. Silvae Sinicae,2011, 47(11), 144—148 |

| (唐丽荣, 黄彪, 戴达松, 欧文, 李玉华, 陈学榕.林业科学, 2011, 47(11), 144—148) | |

| [16] | Gu J., Liang X. R., Preparation of Bagasse Nanocrystalline Cellulose and Rubber Composites CN 105419002A,2016-03-23 |

| (古菊, 梁小容. 一种蔗渣纳米纤维素及其橡胶复合材料的制备方法,CN 105419002A, 2016-03-23) | |

| [17] | Gu J., Liang X. R., Li C. X., Preparation of Bagasse Nanocrystalline Cellulose, CN 105839440A,2016-08-10 |

| (古菊, 梁小容, 李彩新. 一种蔗渣纳米纤维素的制备方法,CN 105839440A, 2016-08-10) | |

| [18] | Chen W. J., Gu J., Xu S. H., Express Polym. Lett., 2014, 8(8), 659—668 |

| [19] | Luo Y. F., Xu S. H., Gu J., Jia D. M., Express Polym. Lett., 2011, 6(1), 14—25 |

| [20] | Xu S., Gu J., Luo Y., Jia D. M., Lin Y., Polym. Composite., 2014, 36(5), 861—868 |

| [21] | Gu J., Chen W. J., Lin L., Luo Y. F., Jia D. M., Chinese J. Polym. Sci., 2013, 31(10), 1382—1393 |

| [22] | Gu J., Li X. H., Jia D. M., Luo Y. F., Cheng R. S., Acta. Polym. Sin., 2009, 1(7), 595—599 |

| (古菊, 李雄辉, 贾德民, 罗远芳, 程镕时.高分子学报, 2009, 1(7), 595—599) | |

| [23] | Gu J., Lin L., Luo Y.F., Jia D. M.,Acta Polym. Sin., 2012, (8), 852—860 |

| (古菊, 林路, 罗远芳, 贾德民. 高分子学报, 2012, (8), 852—860) | |

| [24] | Lima M. M. D., Borsali R., Macromol. Rapid Comm., 2004, 25(7), 771—787 |

| [25] | Thielemans W., Warbey C. R., Walsh D. A., Green Chem., 2009, 11(4), 531—537 |

| [26] | Stephens C. H., Whitmore P. M., Morris H. R., Bier M. E., Biomacromolecules,2008, 9(4), 1093—1099 |

| [27] | Wang N., Nanocrystalline Cellulose: Optical Properties, Thermal Behavior and Surface Modification Research, South China University of Technology, Guangzhou, 2007 |

| (王能. 纳米微晶纤维素: 光学性质、 热行为和表面改性研究, 广州: 华南理工大学, 2007) | |

| 28 | [28] Sain M., Panthapulakkal S., Ind. Crop. Prod., 2006, 23(1), 1—8 |

| [29] | Yue Y., Zhou C., French A. D., Xia G., Han G. P., Wang Q. W., Wu Q. L., Cellulose,2012, 19(4), 1173—1187 |

| [30] | Yue Y. Y., Han J. Q., Han G. P., Aita G. M., Wu Q., Ind. Crop. Prod., 2015, 76, 355—363 |

| [31] | Henrique M. A., Neto W. P. F., Silvério H. A., Martin D. F., Gurgel L. V. A., Ind. Crop. Prod., 2015, 76, 128—140 |

| [32] | Yang H., Yan R., Chen H., Dong H. L., Zheng C., Fuel,2007, 86(12/13), 1781—1788 |

| [33] | Hoi L. W. S., Martincigh B. S., Ind. Crop. Prod., 2013, 47(47), 1—12 |

| [34] | Wang Q.Q., Zhu Q. Q.,Sun J. Z.,Biomass Chem. Eng., 2014, (5), 47—51 |

| (王钱钱, 朱倩倩, 孙建中. 生物质化学工程, 2014, (5), 47—51) | |

| [35] | Wang N., Ding E., Cheng R., Polymer,2007, 48(12), 3486—3493 |

| [36] | Xu Q., Yi J., Zhang X., Zhang H., Eur. Polym. J., 2008, 44(9), 2830—2837 |

| [37] | Angellier H., Molina-Boisseau S., Dufresne A., Macromolecules,2005, 38(22), 9161—9170 |

| [38] | Bendahou A., Kaddami H., Dufresne A., Eur. Polym. J., 2010, 46(4), 609—620 |

| [1] | ZHANG Zhibo, SHANG Han, XU Wenxuan, HAN Guangdong, CUI Jinsheng, YANG Haoran, LI Ruixin, ZHANG Shenghui, XU Huan. Self-Assembly of Graphene Oxide at Poly(3-hydroxybutyrate) Microparticles Toward High-performance Intercalated Nanocomposites [J]. Chem. J. Chinese Universities, 2022, 43(2): 20210566. |

| [2] | XU Huan, KE Lyu, TANG Mengke, SHANG Han, XU Wenxuan, ZHANG Zilin, FU Yanan, HAN Guangdong, CUI Jinsheng, YANG Haoran, GAO Jiefeng, ZHANG Shenghui, HE Xinjian. In⁃situ Liquid Exfoliation of Montmorillonite Nanosheets in Poly(lactic acid) to Resist Oxygen Permeation [J]. Chem. J. Chinese Universities, 2022, 43(11): 20220316. |

| [3] | CHANG Sihui, CHEN Tao, ZHAO Liming, QIU Yongjun. Thermal Degradation Mechanism of Bio-based Polybutylactam Plasticized by Ionic Liquids [J]. Chem. J. Chinese Universities, 2022, 43(11): 20220353. |

| [4] | WANG Ye, ZHANG Xiaosi, SUN Lijing, LI Bing, LIU Lin, YANG Miao, TIAN Peng, LIU Zhongyi, LIU Zhongmin. Morphology Control of SAPO Molecular Sieves under the Assistance of Organosilane [J]. Chem. J. Chinese Universities, 2021, 42(3): 683. |

| [5] | ZHANG Jun, WANG Bin, PAN Li, MA Zhe, LI Yuesheng. Synthesis and Properties of Imidazolium-based Polyethylene Ionomer [J]. Chem. J. Chinese Universities, 2020, 41(9): 2070. |

| [6] | LU Man,SONG Chunmei,WAN Bo. Thixotropic Behavior of Hydrophobically Modified Ethoxylated Urethane-thickened Waterborne Latex † [J]. Chem. J. Chinese Universities, 2020, 41(5): 1108. |

| [7] | WU Fengren,LIU Yongjia,LU Xuemin,ZHU Bangshang. Controllable Preparation of Polydopamine Modified Gold Nanoflowers and Its Application in Photothermal Therapy † [J]. Chem. J. Chinese Universities, 2020, 41(3): 465. |

| [8] |

HAN Hongjing,GE Qin,CHEN Yanguang,WANG Haiying,ZHAO Hongzhi,WANG Yizhen,ZHANG Yanan,DENG Jitong,SONG Hua,ZHANG Mei.

Production of Phenolic Compounds from Bagasse Lignin via Catalytic Pyrolysis of Ca1-xPrxFe |

| [9] | SHI Xiaoyu, WANG Songmeng, LIU Lingyan, CHANG Weixing, LI Jing. Controllable Synthesis of Amphiphilic Block Copolymer PMnEOS-b-PAA and co-Assembly Morphologies of PMDEOS-b-PAA/PS-b-PAA [J]. Chem. J. Chinese Universities, 2020, 41(11): 2545. |

| [10] | WANG Yue, GUO Xiaohong, ZHOU Guangdong, CHENG Tiexin. Effect of Alkyl Benzene Sulfonate Surfactant on Morphology and Structure of Calcium Silicate Hydrate † [J]. Chem. J. Chinese Universities, 2019, 40(9): 1795. |

| [11] | REN Wei, TIAN Ye, XING Lingli, YANG Yuexi, DING Tong, LI Xingang. K Promoted Nanosheets-like Hydrotalcite-derived CoAlO Metal Oxides for Catalytic Soot Combustion [J]. Chem. J. Chinese Universities, 2019, 40(8): 1670. |

| [12] | YANG Jinge, LI Yujie, LU Di, CHEN Yufang, SUN Weiwei, ZHENG Chunman. Morphology Control and Lithium Storage Performance of Micro/nano Li-rich Cathode Material† [J]. Chem. J. Chinese Universities, 2019, 40(7): 1495. |

| [13] | RAN Shiya,SHEN Haifeng,LI Xiaonan,WANG Zilu,GUO Zhenghong,FANG Zhengping. Effect and Mechanism of Rare Earth Trifluoromethanesulfonate on the Thermal Stability of Polypropylene† [J]. Chem. J. Chinese Universities, 2019, 40(6): 1333. |

| [14] | FANG Xijie,LIU Ruiyun,LIN Sen,SHI Lei,WANG Runwei,LI Yi,LI Junying. Synthesis of STW-zeotype Germanosilicate via Steam-assisted Crystallization† [J]. Chem. J. Chinese Universities, 2019, 40(5): 867. |

| [15] | YIN Mengxin,LIU Dongsheng,ZHAO Dongyue,DING Tong,TIAN Ye,LI Xingang. Effect of Copper Doping on Lean NOx Trap Performance of Pt/Ba/CuxMg1-xAl2O4 Catalysts at High Temperatures † [J]. Chem. J. Chinese Universities, 2019, 40(10): 2170. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||