Chem. J. Chinese Universities ›› 2017, Vol. 38 ›› Issue (4): 606.doi: 10.7503/cjcu20160843

• Physical Chemistry • Previous Articles Next Articles

CHEN Wenya1, ZHU Li1, HE Jun2, XIE Yunlong1, LU Jiqing1, LUO Mengfei1,*( )

)

Received:2016-11-25

Online:2017-04-10

Published:2017-03-23

Contact:

LUO Mengfei

E-mail:mengfeiluo@zjnu.cn

CLC Number:

TrendMD:

CHEN Wenya, ZHU Li, HE Jun, XIE Yunlong, LU Jiqing, LUO Mengfei. Preparation of Rh/Al2O3-Cr2O3 Monolithic Catalysts for Dichloromethane Combustion†[J]. Chem. J. Chinese Universities, 2017, 38(4): 606.

| Catalyst | SBET/(m2·g-1) | H2 consumption/(mmol·g-1) | Surface acidity/(μmol·g-1) |

|---|---|---|---|

| 0.4Rh/Al2O3-Cr2O3 | 137 | 1.93 | 1150 |

| Al2O3-Cr2O3 | 122 | 1.54 | 580 |

| 0.4Rh/Cr2O3 | 47 | 1.09 | 270 |

| Cr2O3 | 31 | 0.65 | 280 |

| 0.4Rh/Al2O3 | 210 | 0.39 | 2180 |

| Al2O3 | 207 | 0.11 | 1043 |

Table 1 SBET, H2 consumption and surface acidity data of catalysts

| Catalyst | SBET/(m2·g-1) | H2 consumption/(mmol·g-1) | Surface acidity/(μmol·g-1) |

|---|---|---|---|

| 0.4Rh/Al2O3-Cr2O3 | 137 | 1.93 | 1150 |

| Al2O3-Cr2O3 | 122 | 1.54 | 580 |

| 0.4Rh/Cr2O3 | 47 | 1.09 | 270 |

| Cr2O3 | 31 | 0.65 | 280 |

| 0.4Rh/Al2O3 | 210 | 0.39 | 2180 |

| Al2O3 | 207 | 0.11 | 1043 |

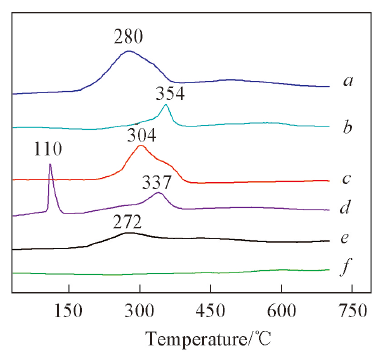

Fig.2 H2-TPR profiles and H2 consumption of various catalystsa. 0.4Rh/Al2O3-Cr2O3; b. Cr2O3; c. Al2O3-Cr2O3; d. 0.4Rh/Cr2O3; e. 0.4Rh/Al2O3; f. Al2O3.

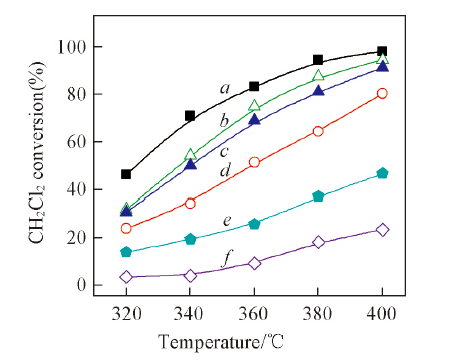

Fig.4 Catalysis performance of CH2Cl2 on various Rh/Al2O3-Cr2O3 catalysts a. 0.4Rh/Al2O3-Cr2O3; b. Al2O3; c. 0.4Rh/Al2O3; d. Al2O3-Cr2O3; e. 0.4Rh/Cr2O3; f. Cr2O3.

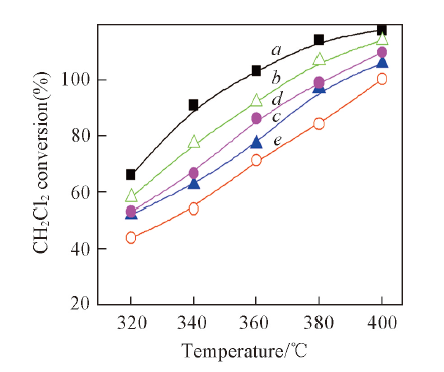

Fig.5 Catalytic performance of xRh/Al2O3-Cr2O3 catalysts a. 0.4Rh/Al2O3-Cr2O3; b. 0.3Rh/Al2O3-Cr2O3; c. 0.2Rh/Al2O3-Cr2O3; d. 0.5Rh/Al2O3-Cr2O3; e. Al2O3-Cr2O3.

| [1] | Shao M., Zhang Y., Zeng L., Tang X., Zhang J., Zhong L., J. Environ. Manage., 2009, 90(1), 512—518 |

| [2] | Dobrzynska E., Posniak M., Szewczynska M., Buszewski B., Crit. Rev. Anal. Chem., 2010, 40(1), 41—57 |

| [3] | Hussmarp J., Eberlein-Koenig B., Darsow U., Breuer K., Mair S., Kraemer U., Behrendt H., J. Allergy Clin. Immun., 2004, 113(2), S56—S57 |

| [4] | International Chemical Safety Cards(ICSC), |

| [5] | Wang L., Sakurai M., Kameyama H., J. Hazard. Mater., 2008, 154(1—3), 390—395 |

| [6] | Pitkäaho S., Matejova L., Ojala S., Gaalova J., Keiski R. L., Appl. Catal. B, 2012, 113/114, 150—159 |

| [7] | Musialik-Piotrowska A., Catal. Today, 2007, 119(1—4), 301—304 |

| [8] | Deng J. G., He S. N., Xie S. H., Yang H. G., Liu Y. X., Dai H. X., Chem. J. Chinese Universities, 2014, 35(6), 1119—1129 |

| (邓积光, 何胜男, 谢少华, 杨黄根, 刘雨溪, 戴洪兴. 高等学校化学学报, 2014,35(6), 1119—1129) | |

| [9] | Ma R. H., Hu P., Jin L. Y., Wang Y. J., Lu J. Q., Luo M. F., Catal. Today, 2011, 175(1), 598—602 |

| [10] | Aranzabal A., González-Marcos J. A., Romero-Sáez M., González-Velasco J. R., Guillemot M., Magnoux P., Appl. Catal. B, 2009, 88(3/4), 533—541 |

| [11] | Zhang L. L., Liu S. Y., Li Z. J., Yao J., Wang G. Y., Chem. J. Chinese Universities, 2014, 35(4), 812—817 |

| (张丽雷, 刘绍英, 李子健, 姚洁, 王公应. 高等学校化学学报, 2014,35(4), 812—817) | |

| [12] | Pitkäaho S., Nevanperä T., Matejova L., Ojala S., Keiski R. L.,Appl. Catal., B,2013, 138/139, 33—42 |

| [13] | Wang Y., Liu H. H., Wang S. Y., Luo M. F., Lu J. Q., J. Catal., 2014, 311, 314—324 |

| [14] | Miranda B., Díaz E., Ordóñez S., Díez F. V., Catal. Commun., 2006, 7(12), 945—949 |

| [15] | Li J., Tang W., Liu G., Li W., Deng Y., Yang J., Catal. Today, 2016, 278, 203—208 |

| [16] | Yang P., Yang S. S., Shi Z. N., Meng Z. H., Zhou R. X., Appl. Catal. B, 2015, 162, 227—235 |

| [17] | He C., Xu B. T., Shi J. W., Qiao N. L., Hao Z. P., Zhao J. L., Fuel Process. Technol., 2015, 130, 179—187 |

| [18] | He F., Luo J. Q., Liu S. T., Chem. Eng. J., 2016, 294, 362—370 |

| [19] | Cao S., Shi M. P., Wang H. Q., Yu F., Weng X., Liu Y., Chem. Eng. J., 2016, 290, 147—153 |

| [20] | Kang M., Lee C. H., Appl. Catal. A, 2004, 266(2), 163—172 |

| [21] | Chen Q. Y., Li N., Luo M. F., Lu J. Q., Appl. Catal. B, 2012, 127, 159—166 |

| [22] | Zhang W. X., Liang Y., Luo J. W., Jia A. P., Wang Y. J., Lu J. Q., J. Mater. Sci., 2016, 51(13), 6488—6496 |

| [23] | Grzybowska B., Słoczyński J., Grabowski R., Wcisło K., Kozłowska A., Stoch J., J. Catal., 1998, 178(2), 687—700 |

| [24] | Wang F., Fan J. L., Zhao Y., Zhang W. X., Liang Y., Lu J. Q., J. Fluorine Chem., 2014, 166, 78—83 |

| [25] | Sermon P. A., Bond G. C., J. Catal. Rev., 2006, 8(1), 211—239 |

| [26] | Burch R., Loader P. K., Cruise N. A., Appl. Catal. A, 1996, 147(2), 375—394 |

| [27] | Pitkäaho S., Matejova L., Jiratova K., Ojala S., Keiski R. L., Appl. Catal. B, 2012, 126, 215—224 |

| [28] | Walker G. S., Pyke D. R., Werrett C. R., Williams E., Bhattacharya A. K., Appl. Surf. Sci., 1999, 147(1—4), 228—234 |

| [29] | Mo W. L., Ma F. Y., Liu Y. E., Liu J. M., Zhong M., Chem. J. Chinese Universities, 2015, 36(12), 2475—2484 |

| (莫文龙, 马凤云, 刘月娥, 刘景梅, 钟梅. 高等学校化学学报, 2015,36(12), 2475—2484) | |

| [30] | Jia W. Z., Jin L. Y., Wang Y. J., Lu J. Q., Luo M. F., Ind. Eng. Chem., 2011, 17(3), 615—620 |

| [31] | Alonso C., Morato A., Medina F., Cesteros Y., Salagre P., Sueiras J. E., Appl. Catal. B, 2003, 40(4), 259—269 |

| [32] | Maupin I., Pinard L., Mijoin J., Magnoux P., J. Catal., 2012, 291, 104—109 |

| [33] | Cao S., Wang H., Yu F., Shi M., Chen S., Weng X., J. Colloid Interface Sci., 2016, 463, 233—241 |

| [1] | WANG Mingzhi, ZHENG Yanping, WENG Weizheng. Catalytic Methane Combustion over CeO2 Supported PdO and Ce1‒x Pd x O2‒δ Species [J]. Chem. J. Chinese Universities, 2022, 43(4): 20210816. |

| [2] | WU Shuaini, ZHU Pengfei, SHI Huaiqi, LI Na, HU Zhaoxia, CHEN Shouwen. Preparation of CoCrx/SAPO-34 Catalyst and Its Catalytic Combustion Performance for 1,2-Dichloroethane [J]. Chem. J. Chinese Universities, 2021, 42(12): 3731. |

| [3] | LI Lingcong, HU Ruisheng, BAI Yaqin, LI Jingjia, TANG Hailian, WANG Junhu, JI Shengfu. Inverse CeO2/La2Sn1.7Co0.3O7-δ Catalyst for Methane Catalytic Combustion† [J]. Chem. J. Chinese Universities, 2015, 36(7): 1328. |

| [4] | ZHANG Lilei, LIU Shaoying, LI Zijian, YAO Jie, WANG Gongying. Catalytic Combustion of Dichloromethane over Cr-13X and K-Cr-13X Zeolites Catalysts† [J]. Chem. J. Chinese Universities, 2014, 35(4): 812. |

| [5] | HE Zhanfeng, WANG Dan, LIU Tao, WANG Huanyi, JIANG Yi. Nb-modified Pd/Al2O3 Catalysts for Benzene Catalytic Combustion† [J]. Chem. J. Chinese Universities, 2014, 35(1): 92. |

| [6] | YE Qing, HUO Fei-Fei, WANG Hai-Ping, WANG Juan, WANG Dao. xAu/α-MnO2 Catalysts: Structure and Catalytic Oxidation of Benzene and Toluene [J]. Chem. J. Chinese Universities, 2013, 34(5): 1187. |

| [7] | ZHU Yi, YAN Chao-Yang, ZHAO Ming, LI Xiao-Shuang, GONG Mao-Chu, CHEN Yao-Qiang. Influence of Zr Content on Stability of (CeMn)1-xZrxO2 Catalysts for Catalytic Combustion of Diesel Soot [J]. Chem. J. Chinese Universities, 2013, 34(2): 394. |

| [8] | SONG Li-Juan*, PAN Ming-Xue, QIN Yu-Cai, JU Xiu-Fang, DUAN Lin-Hai, CHEN Xiao-Lu. Selective Adsorption Desulfurization Performance and Adsorptive Mechanisms of NiY Zeolites [J]. Chem. J. Chinese Universities, 2011, 32(3): 787. |

| [9] | CAO Yu, CHEN Biao-Hua, ZHANG Run-Duo*. Selectively Catalytic Combustion of Acetonitrile by Transition\|metal Supported Mesoporous Molecular Sieve SBA-15 [J]. Chem. J. Chinese Universities, 2011, 32(12): 2849. |

| [10] | CHEN Jie, HU Rui-Sheng*, HU Jia-Nan, LU Tian-Zhu. Catalytic Performance Comparison of the Novel Catalyst La2CuMnO6 and LaMnO3 for Methane Combustion [J]. Chem. J. Chinese Universities, 2011, 32(10): 2396. |

| [11] | SHI Li-Min1, CHU Wei1*, ZHENG Li-Na2, CHEN Mu-Hua1, QU Fen-Fen1, LUO Shi-Zhong1. Low-temperature Catalytic Combustion of Methane over Modified MnOx-CeO2 Mixed Oxide Catalysts [J]. Chem. J. Chinese Universities, 2007, 28(6): 1178. |

| [12] | CHEN Qing-Quan, ZHANG Li-Juan, CHEN Yao-Qiang, WANG Min, GONG Mao-Chu. Effect of Ce0.67Zr0.33O2 on Catalytic Properties of Fe2O3/Al2O3 Catalyst for Methane Combustion [J]. Chem. J. Chinese Universities, 2005, 26(9): 1699. |

| [13] | LIU Jian, ZHAO Zhen, XU Chun-Ming. Characterization of VmTi and KnV0.04Ti Catalysts Supported by Oxide and Their Catalytic Performances for Diesel Soot Combustion [J]. Chem. J. Chinese Universities, 2005, 26(7): 1290. |

| [14] | XU Jin-Guang, TIAN Zhi-Jian, ZHANG Pei-Qing, QU Xiu-Hua, XU Yun-Peng, XU Zhu-Sheng, LIN Li-Wu. Effect of La3+ Substituting Ba2+ on the Structure and Methane Combustion Activity of Ba1-xLaxMn3Al9O19-α Catalysts [J]. Chem. J. Chinese Universities, 2005, 26(11): 2103. |

| [15] | BAO Jia-Qing, XIE Zai-Ku, LU Xian, CHEN Qing-Ling . Distribution of Silicon and Aluminium Atoms as Well as Surface Acid Properties of Aluminated β Zeolite [J]. Chem. J. Chinese Universities, 2002, 23(10): 1930. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||