Chem. J. Chinese Universities ›› 2018, Vol. 39 ›› Issue (6): 1281.doi: 10.7503/cjcu20170842

• Polymer Chemistry • Previous Articles Next Articles

XIAO Lei, ZHANG Chen, HE Meiyu, CHEN Kangcheng*( )

)

Received:2017-12-25

Online:2018-06-10

Published:2018-05-18

Contact:

CHEN Kangcheng

E-mail:chenkc@bit.edu.cn

Supported by:CLC Number:

TrendMD:

XIAO Lei, ZHANG Chen, HE Meiyu, CHEN Kangcheng. Precise Controllable Post-sulfonation for Preparation of Sulfonated Poly(arylene ether sulfone)s and Their Properties for Proton Exchange Membrane†[J]. Chem. J. Chinese Universities, 2018, 39(6): 1281.

| Polymer | IEC/(mmol·g-1) | Water uptake(%) | Swell ratio(%) | ηr f | λg | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Theo.a | Titr.b | NMRc | 30 ℃ | 60 ℃ | 80 ℃ | 30 ℃ | 60 ℃ | |||||

| Δ | Δ | Δ | Δ | |||||||||

| M1-SPAES | 1.09 | 1.03 | 1.05 | 32 | 39 | 42 | 4 | 20 | 7 | 25 | 1.16 | 17 |

| M2-SPAES | 1.34 | 1.26 | 1.31 | 44 | 57 | 67 | 5 | 25 | 11 | 28 | 1.49 | 18 |

| M3-SPAES | 1.50 | 1.44 | 1.49 | 60 | 81 | 128 | 9 | 26 | 11 | 29 | 1.52 | 22 |

| M4-SPAES | 1.60 | 1.54 | 1.57 | 65 | 84 | 133 | 10 | 28 | 15 | 35 | 1.70 | 23 |

| M5-SPAES | 1.70 | 1.63 | 1.65 | 70 | 121 | 163 | 15 | 31 | 23 | 39 | 1.85 | 23 |

| M6-SPAES | 1.83 | 1.80 | 1.89 | 78 | 133 | 188 | 16 | 34 | 28 | 44 | 1.95 | 24 |

| M7-SPAES | 1.95 | 1.94 | 1.95 | 106 | 249 | 467 | 25 | 36 | 29 | 45 | 2.10 | 30 |

| M8-SPAES | 2.30 | 2.23 | 2.28 | 170 | — | — | 31 | 40 | — | — | 2.67 | 41 |

| R1-SPAES | 1.56 | 1.41 | — | 27 | 37 | 42 | 11 | 10 | — | — | 1.51 | 17 |

| R2-SPAES | 1.80 | 1.63 | — | 37 | 50 | 61 | 13 | 14 | — | — | 1.55 | 21 |

Table 1 Physical properties of polymers and membranes

| Polymer | IEC/(mmol·g-1) | Water uptake(%) | Swell ratio(%) | ηr f | λg | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Theo.a | Titr.b | NMRc | 30 ℃ | 60 ℃ | 80 ℃ | 30 ℃ | 60 ℃ | |||||

| Δ | Δ | Δ | Δ | |||||||||

| M1-SPAES | 1.09 | 1.03 | 1.05 | 32 | 39 | 42 | 4 | 20 | 7 | 25 | 1.16 | 17 |

| M2-SPAES | 1.34 | 1.26 | 1.31 | 44 | 57 | 67 | 5 | 25 | 11 | 28 | 1.49 | 18 |

| M3-SPAES | 1.50 | 1.44 | 1.49 | 60 | 81 | 128 | 9 | 26 | 11 | 29 | 1.52 | 22 |

| M4-SPAES | 1.60 | 1.54 | 1.57 | 65 | 84 | 133 | 10 | 28 | 15 | 35 | 1.70 | 23 |

| M5-SPAES | 1.70 | 1.63 | 1.65 | 70 | 121 | 163 | 15 | 31 | 23 | 39 | 1.85 | 23 |

| M6-SPAES | 1.83 | 1.80 | 1.89 | 78 | 133 | 188 | 16 | 34 | 28 | 44 | 1.95 | 24 |

| M7-SPAES | 1.95 | 1.94 | 1.95 | 106 | 249 | 467 | 25 | 36 | 29 | 45 | 2.10 | 30 |

| M8-SPAES | 2.30 | 2.23 | 2.28 | 170 | — | — | 31 | 40 | — | — | 2.67 | 41 |

| R1-SPAES | 1.56 | 1.41 | — | 27 | 37 | 42 | 11 | 10 | — | — | 1.51 | 17 |

| R2-SPAES | 1.80 | 1.63 | — | 37 | 50 | 61 | 13 | 14 | — | — | 1.55 | 21 |

| Polymer | IEC/(mmol·g-1) | TGA | σ/(mS·cm-1) | Ea /(kJ·mol-1) | |||

|---|---|---|---|---|---|---|---|

| Td1/℃ | Td2/℃ | 40 ℃ | 60 ℃ | 80 ℃ | |||

| M1-SPAES | 1.09 | 298 | 494 | 31 | 57 | 94 | 26.7 |

| M2-SPAES | 1.34 | 290 | 463 | 44 | 68 | 99 | 19.1 |

| M3-SPAES | 1.50 | 293 | 506 | 48 | 74 | 110 | 18.9 |

| M4-SPAES | 1.60 | 287 | 488 | 57 | 89 | 129 | 19.5 |

| M5-SPAES | 1.70 | 286 | 499 | 87 | 129 | 175 | 17.2 |

| M6-SPAES | 1.83 | 283 | 491 | 102 | 142 | 184 | 14.5 |

| M7-SPAES | 1.95 | 306 | 483 | 108 | 161 | 188 | 17.5 |

| M8-SPAES | 2.30 | 311 | 496 | 126 | 178 | 211 | 15.1 |

| R1-SPAES | 1.56 | — | — | 68 | 85 | 117 | 14.0 |

| R2-SPAES | 1.80 | — | — | 107 | 133 | 158 | 9.6 |

| SPAES40[ | 1.51 | — | — | 71 | 83 | 127 | 6.8 |

| SPES-20[ | 1.61 | — | — | 100 | 111 | 142 | 4.6 |

| Nafion | 0.91 | — | — | 104 | 142 | 179 | 12.6 |

Table 2 TGA and proton conductivity of PEMs

| Polymer | IEC/(mmol·g-1) | TGA | σ/(mS·cm-1) | Ea /(kJ·mol-1) | |||

|---|---|---|---|---|---|---|---|

| Td1/℃ | Td2/℃ | 40 ℃ | 60 ℃ | 80 ℃ | |||

| M1-SPAES | 1.09 | 298 | 494 | 31 | 57 | 94 | 26.7 |

| M2-SPAES | 1.34 | 290 | 463 | 44 | 68 | 99 | 19.1 |

| M3-SPAES | 1.50 | 293 | 506 | 48 | 74 | 110 | 18.9 |

| M4-SPAES | 1.60 | 287 | 488 | 57 | 89 | 129 | 19.5 |

| M5-SPAES | 1.70 | 286 | 499 | 87 | 129 | 175 | 17.2 |

| M6-SPAES | 1.83 | 283 | 491 | 102 | 142 | 184 | 14.5 |

| M7-SPAES | 1.95 | 306 | 483 | 108 | 161 | 188 | 17.5 |

| M8-SPAES | 2.30 | 311 | 496 | 126 | 178 | 211 | 15.1 |

| R1-SPAES | 1.56 | — | — | 68 | 85 | 117 | 14.0 |

| R2-SPAES | 1.80 | — | — | 107 | 133 | 158 | 9.6 |

| SPAES40[ | 1.51 | — | — | 71 | 83 | 127 | 6.8 |

| SPES-20[ | 1.61 | — | — | 100 | 111 | 142 | 4.6 |

| Nafion | 0.91 | — | — | 104 | 142 | 179 | 12.6 |

| Polymer | IEC/(mmol·g-1) | Ya/GPa | Sb/MPa | Ec(%) | Oxidative stabilityd | |

|---|---|---|---|---|---|---|

| t/h(20 ℃) | t/min(80 ℃) | |||||

| M1-SPAES | 1.09 | 1.19 | 56 | 15 | 216 | 84 |

| M2-SPAES | 1.34 | 1.32 | 61 | 28 | 209 | 65 |

| M3-SPAES | 1.50 | 1.26 | 60 | 15 | 198 | 57 |

| M4-SPAES | 1.60 | 1.25 | 57 | 26 | 183 | 43 |

| M5-SPAES | 1.70 | 1.36 | 52 | 18 | 175 | 24 |

| M6-SPAES | 1.83 | 1.23 | 58 | 28 | 167 | 17 |

| M7-SPAES | 1.95 | 1.29 | 54 | 24 | 167 | 9 |

| M8-SPAES | 2.23 | 1.34 | 51 | 16 | 112 | 5 |

| R1-SPAES | 1.56 | 0.91 | 50 | 15 | — | — |

| R2-SPAES | 1.80 | 0.96 | 54 | 11 | — | — |

Table 3 Mechanical properties and oxidative stability of PEMs

| Polymer | IEC/(mmol·g-1) | Ya/GPa | Sb/MPa | Ec(%) | Oxidative stabilityd | |

|---|---|---|---|---|---|---|

| t/h(20 ℃) | t/min(80 ℃) | |||||

| M1-SPAES | 1.09 | 1.19 | 56 | 15 | 216 | 84 |

| M2-SPAES | 1.34 | 1.32 | 61 | 28 | 209 | 65 |

| M3-SPAES | 1.50 | 1.26 | 60 | 15 | 198 | 57 |

| M4-SPAES | 1.60 | 1.25 | 57 | 26 | 183 | 43 |

| M5-SPAES | 1.70 | 1.36 | 52 | 18 | 175 | 24 |

| M6-SPAES | 1.83 | 1.23 | 58 | 28 | 167 | 17 |

| M7-SPAES | 1.95 | 1.29 | 54 | 24 | 167 | 9 |

| M8-SPAES | 2.23 | 1.34 | 51 | 16 | 112 | 5 |

| R1-SPAES | 1.56 | 0.91 | 50 | 15 | — | — |

| R2-SPAES | 1.80 | 0.96 | 54 | 11 | — | — |

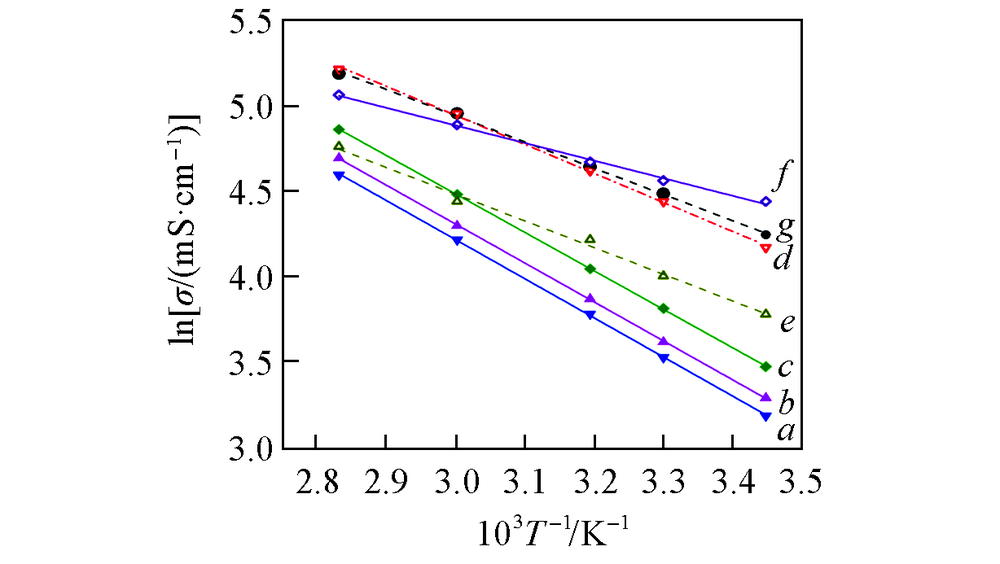

Fig.5 Temperature dependence of proton conductivity of membranesa. M2-SPAES; b. M3-SPAES; c. M4-SPAES; d. M6-SPAES; e. R1-SPAES; f. R2-SPAES; g. Nafion.

| [1] | Kim K., Kim S. K., Park J. O., Choi S. W., J. Membr. Sci., 2017, 537, 11—21 |

| [2] | Savadogo O., J. Power Sources, 2004, 127(12), 135—161 |

| [3] | Chen R., Li G., New J.Chem., 2016, 40(4), 3755—3762 |

| [4] | Gong F. X., Qi Y. H., Xue Q. X., Chem. J. Chinese Universities, 2014, 35(2), 433—439 |

| (宫飞翔, 齐永红, 薛群翔. 高等学校化学学报, 2014, 35(2), 433—439) | |

| [5] | Zhang Z., Wu. L., Xu T., J. Membr. Sci., 2011, 373(12), 160—166 |

| [6] | Wei H., Chen R., Li G., Inter. J. Hydrogen Energy, 2015, 40(41), 14392—14397 |

| [7] | Pang J. H., Feng S. N., Zhang H. B., Jiang Z. H., Wang G. B., RSC Adv., 2015, 5(48), 38298—38307 |

| [8] | Chen K. C., Bai W. X., Zhao Z. P., Liu W. F., Yang Z., Chem. J. Chinese Universities, 2015, 36(4), 781—787 |

| (陈康成, 白文馨, 赵之平, 刘文芳, 杨智. 高等学校化学学报, 2015, 36(4), 781—787) | |

| [9] | Ren J., Zhang S., Liu Y., Wang Y., Pang J., Wang Q., Wang G., J. Membr. Sci., 2013, 434, 161—170 |

| [10] | Wen P. S., Zhong Z., Li L., Shen F., Li X. D., Lee M. H., J. Membr. Sci., 2014, 463, 58—64 |

| [11] | Daryaei A., Miller G. C., Willey J., Roy C. S., Vondrasek B., Kazerooni D., Burtner M. R., Mittelsteadt C., Lesko J. J., Riffle J. S., McGrath J. E., ACS Appl. Mater. Interfaces, 2017, 9(23), 20067—20075 |

| [12] | Tang W. F, Ling Y., Chen S. S., Hu Z. X., Chen S. W., Chem. J. Chinese Universities, 2013, 34(11), 2661—2666 |

| (唐卫芬, 凌瑛, 陈姗姗, 胡朝霞, 陈守文. 高等学校化学学报, 2013, 34(11), 2661—2666) | |

| [13] | Hu Z. X., Tang W. F., Zhang X. L., Bi H. P., Chen S. S., Geng H., Gao Y., Chen S. W., J. Polym. Res., 2016, 23(11), 230 |

| [14] | Abhishek R., Hickner M. A., Ozma L., McGrath J. E., J. Power Sources, 2009, 191, 550—554 |

| [15] | Yu D. M., Yoon. S., Kim T. H., Lee J. Y., Lee J., Hong. Y. T., J. Membr. Sci., 2013, 446(11), 212—219 |

| [16] | Lee S. Y., Yeonhye K., Kim H. J., Solid State Ionics, 2015, 275, 92—96 |

| [17] | Lee H. F., Benjamin B., Huang Y. C., J. Mater. Sci., 2016, 51, 9805—9821 |

| [18] | Hickner M. A., Hossein G., Yu S. K., Brian R., Mcgrath J. E., Chem. Rev., 2004, 104, 4587—4612 |

| [19] | Chen D. Y., Kim S., Li L., Yang G., Hickner M. A., RSC Adv., 2012, 2(21), 8087—8094 |

| [20] | Jin X., Bishop M. P., Ellis T. S., J. British. Polym., 1985, 17(1), 4—10 |

| [21] | Kong L. H., Xiao M., Wang L., Meng Z. Y., Chem. J. Chinese Universities, 2006, 27(6), 1141—1144 |

| (孔令环, 肖敏, 王雷, 孟跃中. 高等学校化学学报, 2006, 27(6), 1141—1144) | |

| [22] | Tao D., Xiang X. Z., Wang L., Acta Polymerica Sinica, 2014, 3(3), 326—332 |

| (陶丹, 向熊志, 王雷. 高分子学报, 2014, 3(3), 326—332) | |

| [23] | Zhuang Z., Qi D., Zhao C. J., Na H., Sensors and Actuators B: Chemical, 2016, 236, 701—711 |

| [24] | Wang F., Hickner M., Kim Y. S., Mcgrath J. E., J. Membr. Sci., 2002, 197, 231—242 |

| [25] | Yue X., Wu W. J., Chen G. D., Yang C. R., Liao S. J., Li X. H., J. Appl. Polym. Sci., 2017, 134(39), 45333 |

| [26] | Lin C. X., Zhuo Y. Z., Hu E. N., Zhang Q. G., Zhu A. M., Liu Q. L., J. Membr. Sci., 2017, 539, 24—33 |

| [27] | Chen K. C., Ji M. D., Chem. J. Chinese Universities, 2016, 37(5), 989—995 |

| (陈康成, 纪梦蝶. 高等学校化学学报, 2016, 37(5), 989—995) | |

| [28] | Zheng J. F., Wang J., Zhang S. B., Yuan T., Yang H., J. Power Sources, 2014, 245(1), 1005—1013 |

| [1] | QIU Xinsheng, WU Qin, SHI Daxin, ZHANG Yaoyuan, CHEN Kangcheng, LI Hansheng. Preparation and High Temperature Fuel Cell Performance of Ionic Crosslinked Sulfonated Polyimides for Proton Exchange Membranes [J]. Chem. J. Chinese Universities, 2022, 43(8): 20220140. |

| [2] | JIA Hongjun, ZHANG Jiatao, MA Zhuoli, WANG Heng, YANG Xinyu, YANG Jiazhi. Preparation of PTFE/PAA/Nafion Composite Membrane by Aqueous Polymerization of Acrylic Acid and Its Properties [J]. Chem. J. Chinese Universities, 2022, 43(11): 20220350. |

| [3] | LIU Jie, LI Jinsheng, BAI Jingsen, JIN Zhao, GE Junjie, LIU Changpeng, XING Wei. Constructing a Water-blocking Interlayer Containing Sulfonated Carbon Tubes to Reduce Concentration Polarization in Direct Methanol Fuel Cells [J]. Chem. J. Chinese Universities, 2022, 43(11): 20220420. |

| [4] | FU Zhinan, TAN Yunlong, XIAO Guyu, YAN Deyue. Synthesis and Properties of Sulfonated Poly(phthalazinone ether phosphine oxide)s with Perfluorobiphenyl Moieties for Proton Exchange Membranes [J]. Chem. J. Chinese Universities, 2021, 42(8): 2635. |

| [5] | PU Yangyang, NING Cong, LU Yao, LIU Lili, LI Na, HU Zhaoxia, CHEN Shouwen. Preparation and Characterizations of Cross-linked Sulfonated Poly(ether ether ketone)/Partially Fluorinated Sulfonated Poly(aryl ether sulfone) Blend Membranes [J]. Chem. J. Chinese Universities, 2021, 42(6): 2002. |

| [6] | CAO Kaiyue, PENG JinWu, LI Hongbin, SHI Chengying, WANG Peng, LIU Baijun. High-temperature Proton Exchange Membranes Based on Cross-linked Polybenzimidazole/hyperbranched-polymer Blends [J]. Chem. J. Chinese Universities, 2021, 42(6): 2049. |

| [7] | LIANG Minhui, WANG Peng, LI Hongbin, LI Tianyang, CAO Kaiyue, PENG Jinwu, LIU Zhenchao, LIU Baijun. Preparation of High-temperature Proton Exchange Membranes Based on Semi-interpenetrating Polymer Networks [J]. Chem. J. Chinese Universities, 2020, 41(12): 2845. |

| [8] | SONG Xipeng, LIU Jinyu, WANG Lihua, HAN Xutong, HUANG Qinglin. Preparation of Polybenzimidazole/Polyvinylpyrrolidone Proton Exchange Membranes for Vanadium Redox Flow Battery† [J]. Chem. J. Chinese Universities, 2019, 40(7): 1543. |

| [9] | ZHU Yuxin,HARAGIRIMANA Alphonse,LU Yao,BUREGEYA Ingabire Providence,NING Cong,LI Na,HU Zhaoxia,CHEN Shouwen. Preparation and Properties of Filling-type Sulfonated Poly(arylene ether sulfone)/Poly(ether sulfone) Composite Membranes with Microporous Structures† [J]. Chem. J. Chinese Universities, 2019, 40(5): 1051. |

| [10] | REN Xiaorui,LIU Chao,LI Huanhuan,YANG Jingshuai,HE Ronghuan. Siloxane Crosslinked Imidazolium PPO/PTFE Membranes for High Temperature Proton Exchange Membranes† [J]. Chem. J. Chinese Universities, 2019, 40(5): 1089. |

| [11] | LIU Jiaming,FU Kailin,ZHANG Ze,GUO Wei,PAN Mu. Ultra-low Pt Loading Cathodic Catalyst Layer Prepared on Textured Gas Diffusion Layer by Magnetron Sputtering Method for Hydrogen-oxygen Fuel Cells† [J]. Chem. J. Chinese Universities, 2019, 40(3): 542. |

| [12] | CHEN Yuhan,HUANG Xuehong. Preparation and Performance of the Self-crosslinking Sulfonated Poly(ether ether ketone) Proton Exchange Membrane† [J]. Chem. J. Chinese Universities, 2019, 40(2): 410. |

| [13] | LIU Bo,ZOU Nan,ZHANG Yuxia,SHI Haifeng. Structure and Properties of Sulfonated Poly(ether ether ketone)/Laponite Proton Exchange Membrane for All Vanadium Redox Flow Battery † [J]. Chem. J. Chinese Universities, 2019, 40(10): 2186. |

| [14] | ZHU Xingye,QIAN Huidong,JIANG Jingjing,YUE Zhouying,XU Jianfeng,ZOU Zhiqing,YANG Hui. Cross-linking of Imidazole-grafted Sulfonated Poly(ether ether ketone) as Proton Exchange Membranes for Direct Methanol Fuel Cells† [J]. Chem. J. Chinese Universities, 2018, 39(9): 2046. |

| [15] | WANG Peng, WU Xian, ZHANG Hanyu, YOU Kaiyuan, LIU Zhenchao, LIU Baijun. Preparation of the Blend Membranes Based on Sulfonated Polyetheretherketoneketone and Amine-terminated Hyperbranched Polyimide† [J]. Chem. J. Chinese Universities, 2018, 39(3): 405. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||