Chem. J. Chinese Universities ›› 2018, Vol. 39 ›› Issue (6): 1132.doi: 10.7503/cjcu20170796

• Articles: Inorganic Chemistry • Previous Articles Next Articles

CHENG Yanyan, SUI Guanghui, CHEN Zhimin, LIU Huan, DUAN Yajun, WANG Xiaofeng, YANG Xiaomin*( ), WANG Zichen

), WANG Zichen

Received:2017-12-08

Online:2018-06-10

Published:2018-05-15

Contact:

YANG Xiaomin

E-mail:xmyang@jlu.edu.cn

Supported by:CLC Number:

TrendMD:

CHENG Yanyan, SUI Guanghui, CHEN Zhimin, LIU Huan, DUAN Yajun, WANG Xiaofeng, YANG Xiaomin, WANG Zichen. Highly Efficient Utilization of Rice Husk Char to Prepare Carbon Adsorbent and Calcium Silicate†[J]. Chem. J. Chinese Universities, 2018, 39(6): 1132.

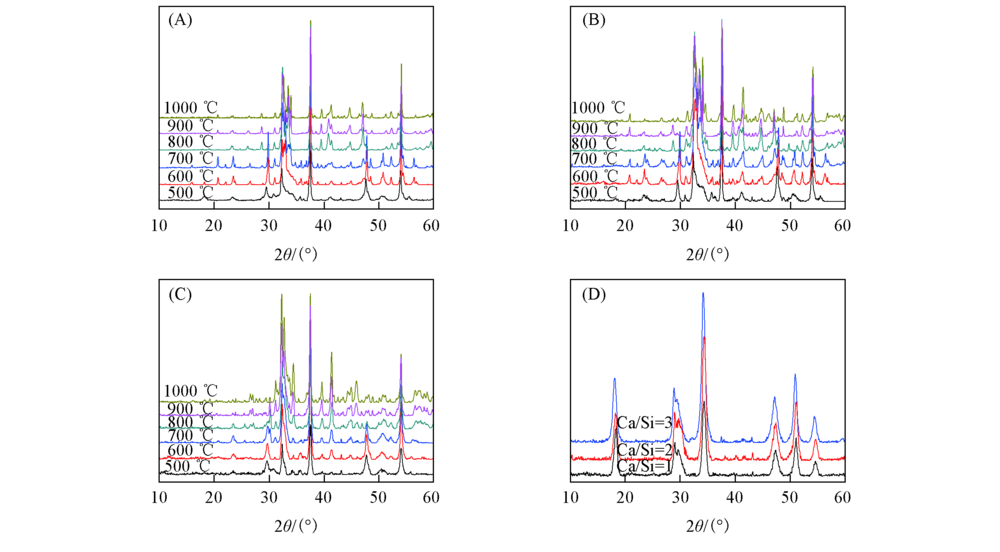

Fig.3 XRD patterns of rice husk based calcium silicate prepared at different temperatures and Ca/Si ratios Ca/Si molar ratio: (A) 3; (B) 2; (C) 1; (D) Untreated.

| [1] | Swain P. K., Das L. M., Naik S. N., Renew. Sust. Energ. Rev., 2011, 15, 4917—4933 |

| [2] | Wobiwo F. A., Emaga T. H., Fokou E., Boda M., Gillet S., Deleu M., Richel A., Gerin P. A.,Biomass Conversion and Biorefinery, 2017, 7, 167—177 |

| [3] | Al-Hamamre Z., Saidan M., Hararah M., Rawajfeh K., Alkhasawneh H. E., Al-Shannag M., Renew. Sust. Energ. Rev., 2017, 67, 295—314 |

| [4] | Strezov V., Evans T.J., Biomass Processing Technologies, CRC Press/Taylor & Francis, Boca Raton, 2014 |

| [5] | Chen T. J., Wu C., Liu R. H., Bioresource Technol., 2011, 102, 9236—9240 |

| [6] | Alvarez J., Lopez G., Amutio M., Bilbao J., Olazar M., Fuel, 2014, 128, 162—169 |

| [7] | Bridgwater A.V., Biomass Bioenergy, 2012, 38, 68—94 |

| [8] | Williams A., Jones J. M., Ma L., Pourkashanian M., Prog. Energ. Combust., 2012, 38, 113—137 |

| [9] | Ding L.L., Zou B., Liu H. Q., Li Y. N., Wang Z. C., Su Y., Guo Y. P., Wang X. F.,Chem. Eng. J., 2013, 225, 300—305 |

| [10] | Wang L. L., Guo Y. P., Zou B., Rong C. G., Ma X. Y., Qu Y. N., Li Y., Wang Z. C., Bioresource Technol., 2011, 102, 1947—1950 |

| [11] | Ding L. L., Zou B., Li Y. N., Liu H. Q., Wang Z. C., Zhao C., Su Y., Guo Y. P., Colloid Surface A, 2013, 423, 104—111 |

| [12] | Zhang W. L., Lin N., Liu D. B., Xu J. H., Sha J. X., Yin J., Tan X. B., Yang H. P., Lu H. Y., Lin H. B.,Energy, 2017, 128, 618—625 |

| [13] | Peng J. B., Zhang W. L., Liu Y., Jiang Y. H., Ni L., Qiu J., Water Air Soil Poll., 2017, 228, 9 |

| [14] | Tseng R. L., Tseng S. K., J. Colloid. Interf. Sci., 2005, 287, 428—437 |

| [15] | Ding L. L., Zou B., Gao W., Liu Q., Wang Z. C., Guo Y. P., Wang X. F., Liu Y. H.,Colloid Surface A, 2014, 446, 1—7 |

| [16] | Liu X. Y., Li Z., Chen H. Z., Yang L., Tian Y. M., Wang Z. C., Res. Chem. Intermediat., 2016, 42, 3887—3903 |

| [17] | Deng M., Zhang G. Y., Zeng Y., Pei X. J., Huang R. Q., Lin J. H., J. Alloy. Compd., 2016, 683, 412—417 |

| [18] | Naskar M. K., Chatteljee M., Mater. Lett., 2005, 59, 998—1003 |

| [19] | Yang X. M., Liang Y., Cheng Y. Y., Song W., Wang X. F., Wang Z. C., Qiu J. S., Catal. Commun., 2014, 47, 28—31 |

| [20] | Yang X. M., Liang Y., Zhao X., Song Y. F., Hu L. H., Wang X. F., Wang Z. C., Qiu J. S.,RSC Adv., 2014, 4, 31932—31936 |

| [21] | Liu Y. H., Chen Z. H., Wang X. F., Liang Y., Yang X. M., Wang Z. C., ACS Sustain. Chem. Eng., 2017, 5, 744—751 |

| [22] | Liang Y., Chen Z. H., Liang B. Y., Hu Z., Yang X. M., Wang Z. C., Chem. J. Chinese Universities, 2016, 37(6), 1123—1127 |

| (梁玉, 陈志浩, 梁宝炎, 胡哲, 杨晓敏, 王子忱. 高等学校化学学报, 2016, 37(6), 1123—1127) | |

| [23] | Ding L. L., Wang Z. C., Li Y. N., Du Y. L., Liu H. Q., Guo Y. P., Mater. Lett., 2012, 74, 111—114 |

| [24] | Wu M. B., Li L. Y., Liu J., Li Y., Ai P. P., Wu W. T., Zheng J. T., New Carbon Mater., 2015, 30, 471—475 |

| [25] | Wu M. B., Li R. C., He X. J., Zhang H. B., Sui W. B., Tan M. H., New Carbon Mater., 2015, 30, 86—91 |

| [26] | He X. J., Li X. J., Wang X. T., Zhao N., Yu M. X., Wu M. B., New Carbon Mater., 2014, 29, 493—502 |

| [27] | He X.J., Zhang N., Shao X. L., Wu M. B., Yu M. X., Qiu J. S., Chem. Eng. J., 2016, 297, 121—127 |

| [28] | Asasian N., Kaghazchi T., Soleimani M., J. Ind. Eng. Chem., 2012, 18, 283—289 |

| [29] | Li Y. C., Shao J. G., Wang X. H., Deng Y., Yang H. P., Chen H. P., Energ. Fuel., 2014, 28, 5119—5127 |

| [30] | Ahmed M. B., Zhou J. L., Ngo H. H., Guo W. S., Chen M. F., Bioresource Technol., 2016, 214, 836—851 |

| [31] | Kim E., Jung C. I., Han J., Her N., Park C. M., Jang M., Son A., Yoon Y., J. Ind. Eng. Chem., 2016, 36, 364—371 |

| [32] | Fan Y., Wang B., Yuan S. H., Wu X. H., Chen J., Wang L. L., Bioresource Technol., 2010, 101, 7661—7664 |

| [33] | Naskar M. K., Kundu D., Chatterjee M., J. Am. Ceram. Soc., 2012, 95, 925—930 |

| [34] | Khoshbin R., Karimzadeh R., Adv. Powder Technol., 2017, 28, 973—982 |

| [35] | Setthaya N., Chindaprasirt P., Yin S., Pimraksa K., Powder Technol., 2017, 313, 417—426 |

| [36] | Sinyoung S., Kunchariyakun K., Asavapisit S., MacKenzie K. J. D., J. Environ. Manage., 2017, 190, 53—60 |

| [37] | Udawatte C. P., Yanagisawa K., Kamakura T., Matsumoto Y., Yamasaki N., Mater. Res. Innov., 2000, 3, 297—301 |

| [38] | Ding L. L., Zou B., Shen L., Zhao C., Wang Z. C., Guo Y. P., Wang X. F., Liu Y. H.,Colloid Surface A, 2014, 446, 90—96 |

| [39] | Wang L. L., Guo Y. P., Zhu Y. C., Li Y., Qu Y. N., Rong C. G., Ma X. Y., Wang Z. C., Bioresource Technol., 2010, 101, 9807—9810 |

| [40] | Liu Y., Guo Y. P., Zhu Y. C., An D. M., Gao W., Wang Z., Ma Y. J., Wang Z. C., J. Hazard. Mater., 2011, 186, 1314—1319 |

| [41] | Liu Y., Guo Y. P., Gao W., Wang Z., Ma Y. J., Wang Z. C., J. Clean. Prod., 2012, 32, 204—209 |

| [42] | Brunauer S., Deming L. S., Deming W. E., Teller E., J. Am. Chem. Soc., 1940, 62, 1723—1732 |

| [43] | Zhang M. M., A Study on the Adsorption of Malachite Green and P-Chlorophenol from the Aqueous Solution by Activated Carbon Prepared from Nutshel., Zhengzhou Universit.,Zhengzhou, 2012 |

| (张曼曼. 核桃壳基活性炭的制备及对水体中孔雀石绿和4-氯苯酚的吸附研究, 郑州: 郑州大学, 2012) | |

| [44] | Nettleship I., Slavick K. G., Kim Y. J., Kriven W. M., J. Am. Chem. Soc., 2010, 76, 2628—2634 |

| [45] | Nishi F., Takeuchi Y., Maki I., Z. Kristallogr., 1985, 172, 297—314 |

| [46] | Zhang J. Q., Studyon the Synthesis of Calcium Silicate-Based Mineral Materials from Alkaline Sodium Silicate Solutio., Central South Universit., Changsha, 2012 |

| (张吉清. 含碱硅酸钠溶液合成硅酸钙基矿物材料的研究, 长沙: 中南大学, 2012) | |

| [47] | Zhang H. X., Zhao X., Ding X. F., Lei H., Chen X., An D. M., Li Y. L., Wang Z. C.,Bioresource Technol., 2010, 101, 1263—1267 |

| [1] | WANG Yue, GUO Xiaohong, ZHOU Guangdong, CHENG Tiexin. Effect of Alkyl Benzene Sulfonate Surfactant on Morphology and Structure of Calcium Silicate Hydrate † [J]. Chem. J. Chinese Universities, 2019, 40(9): 1795. |

| [2] | SUI Guanghui,CHENG Yanyan,CHEN Zhimin,WEI Qingling,WANG Xiaofeng,YANG Xiaomin,WANG Zichen. Comprehensive Utilization of Rice Husk to Prepare Xylose, Capacitance Carbon and Calcium Silicate Whiskers† [J]. Chem. J. Chinese Universities, 2019, 40(2): 224. |

| [3] | GUO Zhi-Qiang, CHEN Feng, DENG Yi, WAN Qian-Hong, CHEN Lei*. Preparation of Mercaptopropyl Bonded Silica by Atomic Layer Deposition and Its Adsorption of Palladium(Ⅱ) Ions [J]. Chem. J. Chinese Universities, 2009, 30(10): 2017. |

| [4] | FAN Min-Guang1, FANG Jin-Long1, ZHOU Long-Chang1, LI Wang-Liang2, LI Bin1*, XING Jian-Min2, LIU Zi-Li1. Distribution of the Cu Ions in the CuHY Zeolite and Its Performance of Desulfurization [J]. Chem. J. Chinese Universities, 2008, 29(9): 1834. |

| [5] | WANG Cun-Guo1*, HE Li-Xia1, DONG Xian-Guo1, GAO Xiao-Ping1, LIU Wei1, DONG Xiao-Chen1,2, YUAN Tao1, ZHANG Jun1. Preparation and Properties of Superabsorbent by Graft Co-polymrization of Acrylic Acid onto Different Celluloses of Crops Stems [J]. Chem. J. Chinese Universities, 2007, 28(9): 1787. |

| [6] | XU Kun1,2, CHEN Qiang1,2, XIANG Sheng1,2, YUE Yu-Mei1,2, ZHANG Wen-De1, WANG Pi-Xin1. Structure and Characteristics of Polyampholyte Super-absorbent Nanocomposite [J]. Chem. J. Chinese Universities, 2006, 27(12): 2417. |

| [7] | YAN Qing-Zhi, SU Xin-Tai, ZHANG Wen-Feng, GE Chang-Chun. Preparation of Starch-g-Sodium Acrylate/Acrylamide Superabsorbent via Frontal Polymerization [J]. Chem. J. Chinese Universities, 2005, 26(7): 1363. |

| [8] | YAN Li-Kai, LAN Ya-Qian, SU Zhong-Min, QIU Yong-Qing, SHAO Chen, LI Bao-Li,WANG Rong-Shun. Quantum Chemistry Study on Stability and Reactivity of Reactive Intermediate of Starch Super-water-absorbent Resin [J]. Chem. J. Chinese Universities, 2003, 24(2): 297. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||