Chem. J. Chinese Universities ›› 2018, Vol. 39 ›› Issue (5): 1091.doi: 10.7503/cjcu20170664

Previous Articles Next Articles

REN Huicheng, WU Yingfei, LIU Dandan, NIE Huarong*, HE Aihua*

Received:2017-09-30

Online:2018-01-13

Published:2018-01-13

Contact:

NIE Huarong,HE Aihua

Supported by:CLC Number:

TrendMD:

REN Huicheng,WU Yingfei,LIU Dandan,NIE Huarong,HE Aihua. Crystallization, Nucleation and Kinetics of TPI in SSBR/TPI Blends†[J]. Chem. J. Chinese Universities, 2018, 39(5): 1091.

| mSSBR/mTPI | Xα(%) | Xβ(%) | Xc (%) | Xc,TPI (%) |

|---|---|---|---|---|

| 0/100 | 67.4 | 32.6 | 30.1 | 30.1 |

| 10/90 | 66.1 | 33.9 | 29.3 | 32.5 |

| 20/80 | 65.6 | 34.4 | 26.3 | 32.9 |

| 40/60 | 64.9 | 35.1 | 19.9 | 33.2 |

| 80/20 | 35.2 | 64.8 | 9.8 | 49.2 |

| 90/10 | 5.2 | 94.8 | 5.9 | 53.2 |

Table 1 Values of Xα, Xβ, total crystallinity and normalized TPI crystallinity calculated from WAXD

| mSSBR/mTPI | Xα(%) | Xβ(%) | Xc (%) | Xc,TPI (%) |

|---|---|---|---|---|

| 0/100 | 67.4 | 32.6 | 30.1 | 30.1 |

| 10/90 | 66.1 | 33.9 | 29.3 | 32.5 |

| 20/80 | 65.6 | 34.4 | 26.3 | 32.9 |

| 40/60 | 64.9 | 35.1 | 19.9 | 33.2 |

| 80/20 | 35.2 | 64.8 | 9.8 | 49.2 |

| 90/10 | 5.2 | 94.8 | 5.9 | 53.2 |

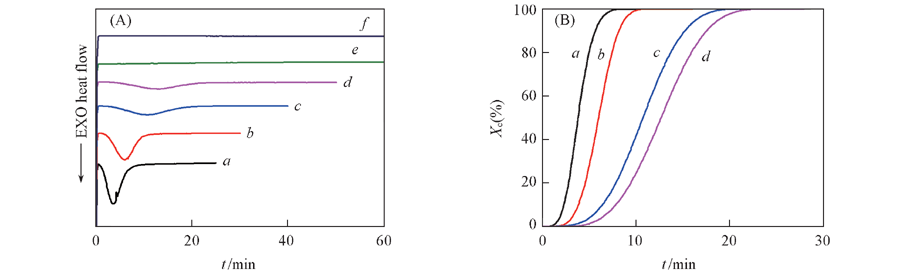

Fig.5 DSC(A) and isothermal crystallization(B) curves of SSBR/TPI blends at 35 ℃ Note: mSSBR/mTPI: a. 0/100; b. 10/90; c. 20/80; d. 40/60; e. 80/20; f. 90/10.

| mSSBR/mTPI | ΔHc/(J∙g-1) | ΔHc,TPI/(J∙g-1) | t1/2/min |

|---|---|---|---|

| 0/100 | 42.3 | 42.3 | 3.8 |

| 10/90 | 38.4 | 42.7 | 6.0 |

| 20/80 | 34.5 | 43.1 | 10.8 |

| 40/60 | 26.3 | 43.8 | 12.6 |

Table 2 Crystallization parameters of SSBR/TPI blends at 35 ℃

| mSSBR/mTPI | ΔHc/(J∙g-1) | ΔHc,TPI/(J∙g-1) | t1/2/min |

|---|---|---|---|

| 0/100 | 42.3 | 42.3 | 3.8 |

| 10/90 | 38.4 | 42.7 | 6.0 |

| 20/80 | 34.5 | 43.1 | 10.8 |

| 40/60 | 26.3 | 43.8 | 12.6 |

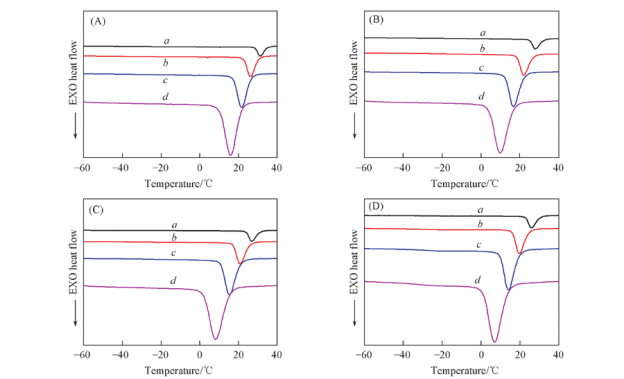

Fig.6 DSC curves of SSBR/TPI blends undergoing non-isothermal crystallization with different cooling rates for mSSBR/mTPI of 0/100(A), 10/90(B), 20/80(C) and 40/60(D) Note:Cooling rate/(℃∙min-1): a. 2; b. 5; c. 10; d. 20.

| [1] | Bunn C.W., Proc. R. Soc. London, 1942, 180(980), 40—66 |

| [2] | Mandelkern L., Quinn F.A., Roberts D. E., Rubber Chem. Technol., 1956, 29(4), 1181—1194 |

| [3] | Song J.S., Huang B. C., Yu D. S., [J]. Appl. Polym. Sci., 2001, 82(1), 81—89 |

| [4] | Wang X.J., Nie H. R., Liu D. D., He A. H., Polym. Int., 2017, 1473—1479 |

| [5] | Manzur A., [J]. Macromol. Sci. Phys., 2006, (3), 329—337 |

| [6] | Intyre D.M., [J]. Macromol. Sci. Phys., 1988, (1), 79—98 |

| [7] | Boochathum P., Chiewnawin S., Eur. Polym. J., 2001, 37(3), 429—434 |

| [8] | Yao K.C., Nie H. R., Liang Y. R., He A. H., Polymer, 2015, 80, 259—264 |

| [9] | Nie H.R., Liu D. D., Liu C. G., Wang X. J., He A. H., Polymer, 2017, 117, 11—16 |

| [10] | Yao K.C., Nie H. R., Ma Y. S., Wang R. G., Wang X. J., He A. H., Chem. [J]. Chinese Universities, 2016, 37(12), 2315—2322 |

| (姚坤承, 聂华荣, 马韵升, 王日国, 王晓建, 贺爱华. 高等学校化学学报, 2016, 37(12), 2315—2322) | |

| [11] | Pizzoli M., Scandola M., Ceccorulli G., Macromolecules, 1994, 27(17), 4755—4761 |

| [12] | Chen H., Lin T., Macromolecules, 1998, 31(7), 2255—2264 |

| [13] | Xing P.X., Dong L. S., An Y. X., Feng Z. L., Avella M., Macromolecules, 1997, 30(9), 2726—2733 |

| [14] | Huang C.I., Chen J. R., [J]. Appl. Polym. Sci., 2001, 39(39), 2705—2715 |

| [15] | Chen H.L., Wang S. F., Polymer, 2000, 41(14), 5157—5164 |

| [16] | Nishi T., Wang T.T., Macromolecules, 1975, 8(6), 909—915 |

| [17] | Weng G.S., Bao J. B., Xu Y. C., Chen Z. R., [J]. Polym. Res., 2013, 20(3), 104 |

| [18] | Yang J., Liang Y., Luo J., Macromolecules, 2012, 45(10), 4254—4261 |

| [19] | Fischer E., Henderson J.F., J. Polym. Sci., Part B: Polym. Phys., 1967, 5(2), 377—390 |

| [20] | Davies C K L, Long O E., [J]. Mater. Sci., 1979, 14(11), 2529—2536 |

| [21] | Jeziorny A., Polymer, 1978, 19(10), 1142—1144 |

| [22] | Ozawa T., Polymer, 1971, 12(3), 150—158 |

| [1] | HAN Jiahui,HUANG Hanxiong,HUANG Yuxiao. Improving Crystallization Behavior and Melt Strength of Poly(lactic acid) via Adding Talc and PLA-g-MAH† [J]. Chem. J. Chinese Universities, 2018, 39(9): 2089. |

| [2] | ZHANG Lili, CHEN Qiaoyue, ZHOU Hengwei, SHI Tongfei, HUANG Yineng. Influences of Topological Chain Structures to the Crystallization of Block Copolymers† [J]. Chem. J. Chinese Universities, 2015, 36(9): 1832. |

| [3] | ZHOU Li-Juan, ZHANG Xiu-Qin, LI Rong-Bo, SU Yun-Lan, ZHAO Ying, XU Duan-Fu. Effect of γ-Ray Irradiation on Chain Structure and Crystallization Behavior of Isotactic Polypropylene [J]. Chem. J. Chinese Universities, 2012, 33(04): 850. |

| [4] | LUO Fa-Liang, ZHANG Xiu-Qin, LI Rong-Bo, GAN Zhi-Hua, JI Jun-Hui, WANG Du-Jin. Effect of Self-nucleation Process on Isothermal Crystallization Behavior of Polybutylene Succinate [J]. Chem. J. Chinese Universities, 2010, 31(6): 1274. |

| [5] | ZHU Ming, LI Ya-Peng, TANG Jun, WANG Shu-Wei, WANG Jing-Yuan*. Nonisothermal Crystallization Kinetics of P(BHB-CL) [J]. Chem. J. Chinese Universities, 2010, 31(3): 607. |

| [6] | LI Gui-Juan1,2*; XU Xiao-Duo1; XU Xue-Li1; YU Bao-Jie1; LI Yi1; ZHOU En-Le2. Sudies on Non-isothermal Melt Crystallization Kinetics in PET/PEN/DBS Blends [J]. Chem. J. Chinese Universities, 2006, 27(6): 1173. |

| [7] | HE Yong, GAO Zhao-Fen, XIN Yan, YU Ying, LI Su-Ming, FAN Zhong-Yong. Crystallization Behavior of Poly(L-lactide) [J]. Chem. J. Chinese Universities, 2006, 27(4): 745. |

| [8] | LIU Xiu-Xia1,2, CHEN Yong1, CHEN Ye1, ZHANG Wan-Xi2, CHEN Wei3, YANG De-Cai1. Crystallization Kinetics and Morphology of High Impact Polypropylene [J]. Chem. J. Chinese Universities, 2006, 27(12): 2430. |

| [9] | LV Kang-Bo, CHEN Ye, YANG De-Cai . Direct Formation of Isotactic Poly(1-butene) Form Ⅰ Crystals in Solution-cast Thin Films [J]. Chem. J. Chinese Universities, 2005, 26(1): 195. |

| [10] | TONG Cui-Yan, XIE De-Min, YANG De-Cai . Effects of Self-seeding Nucleation on Crystallization Behavior of Syndiotactic 1,2-Polybutadiene [J]. Chem. J. Chinese Universities, 2005, 26(1): 197. |

| [11] | WANG Han-Fu, ZHAO Xiao-Gang, LIU Xin-Cai, CHEN Liang, WANG Li-Feng, CHEN Chun-Hai , WU Zhong-Wen. Nonisothermal Crystallization Kinetics of PEEK-PEDEK Block Copolymer [J]. Chem. J. Chinese Universities, 2004, 25(7): 1378. |

| [12] | ZHAO Xiao-Gang, CHEN Chun-Hai, LIU Xin-Cai, ZHANG Wan-Jin . Nonisothermal Melt Crystallization Kinetics Studies on Thio-ether-contained Poly(ether ether ketone ketone) Copolymer [J]. Chem. J. Chinese Universities, 2004, 25(4): 778. |

| [13] | WANG Song, YANG De-Cai . Isothermal Crystallization Kinetics of iPP During Self-nucleation Process [J]. Chem. J. Chinese Universities, 2004, 25(1): 191. |

| [14] | GAO Sheng-Li, FANG Yan, HU Rong-Zu, CHEN San-Ping, SHI Qi-Zhen . Crystallization Kinetics of Zn(Val)SO4·H2O in Mixed Solvent of Water with Acetone [J]. Chem. J. Chinese Universities, 2003, 24(3): 381. |

| [15] | LIN Zhong-Hua, PENG Mao, ZHENG Qiang . Studies on Crystallization Behavior of Polypropylene Catalloys [J]. Chem. J. Chinese Universities, 2003, 24(10): 1923. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||