Chem. J. Chinese Universities ›› 2017, Vol. 38 ›› Issue (11): 2006.doi: 10.7503/cjcu20170192

• Physical Chemistry • Previous Articles Next Articles

LIU Yaoyao1, DING Tong1,*( ), ZHAO Dongyue1, GAO Zhongnan1, GUO Lihong1,2, TIAN Ye1, LI Xingang1

), ZHAO Dongyue1, GAO Zhongnan1, GUO Lihong1,2, TIAN Ye1, LI Xingang1

Received:2017-03-29

Online:2017-11-10

Published:2017-10-16

Contact:

DING Tong

E-mail:d_tong@tju.edu.cn

Supported by:CLC Number:

TrendMD:

LIU Yaoyao, DING Tong, ZHAO Dongyue, GAO Zhongnan, GUO Lihong, TIAN Ye, LI Xingang. Effect of Potassium Loading on the NOx Storage and Reduction Performance of the CuO/K2CO3/MgAl2O4 Catalyst at High Temperature†[J]. Chem. J. Chinese Universities, 2017, 38(11): 2006.

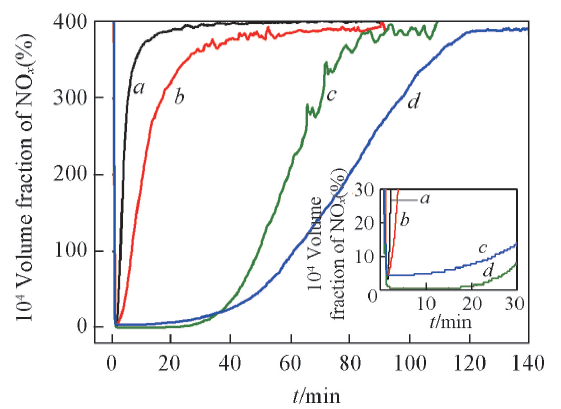

Fig.1 Isothermal NOx storage curves of the CuO/K2CO3/MgAl2O4 catalysts with different K loadingsa. CuO/0K2CO3/MgAl2O4; b. CuO/5%K2CO3/MgAl2O4; c. CuO/10%K2CO3/MgAl2O4; d. CuO/20%K2CO3/MgAl2O4.

| Catalyst | NRP(%) | NSC(mmol·g-1) | NO conversion(%) |

|---|---|---|---|

| CuO/0K2CO3/MgAl2O4 | 57.9 | 0.19 | 33.4 |

| CuO/5%K2CO3/MgAl2O4 | 68.2 | 0.38 | 33.9 |

| CuO/10%K2CO3/MgAl2O4 | 99.9 | 1.56 | 33.7 |

| CuO/20%K2CO3/MgAl2O4 | 98.4 | 1.64 | 33.2 |

Table 1 NRP, NSC and NO conversion of the catalysts*

| Catalyst | NRP(%) | NSC(mmol·g-1) | NO conversion(%) |

|---|---|---|---|

| CuO/0K2CO3/MgAl2O4 | 57.9 | 0.19 | 33.4 |

| CuO/5%K2CO3/MgAl2O4 | 68.2 | 0.38 | 33.9 |

| CuO/10%K2CO3/MgAl2O4 | 99.9 | 1.56 | 33.7 |

| CuO/20%K2CO3/MgAl2O4 | 98.4 | 1.64 | 33.2 |

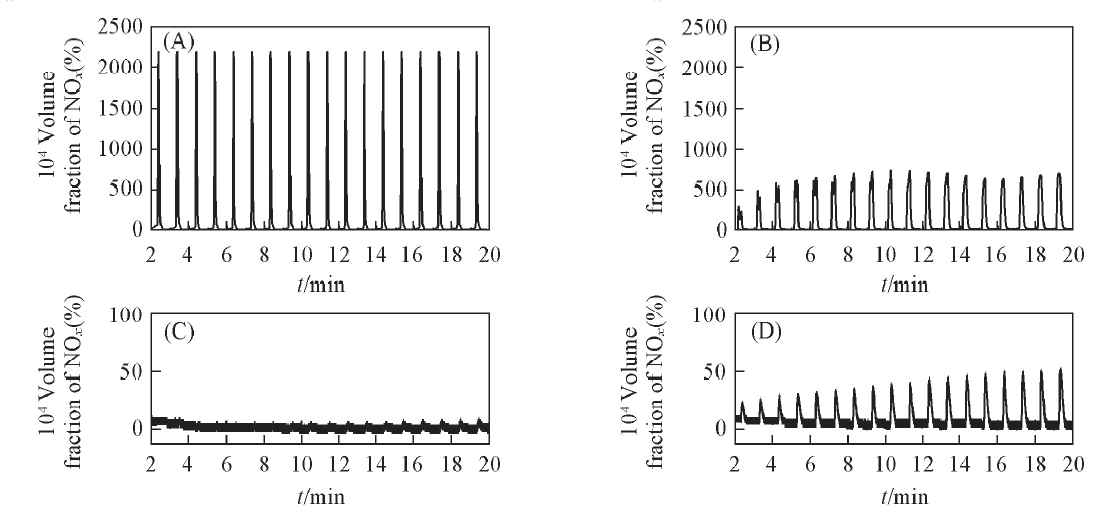

Fig.2 NOx concentration curves during the lean/rich cycles(A) CuO/0K2CO3/MgAl2O4; (B) CuO/5%K2CO3/MgAl2O4; (C) CuO/10%K2CO3/MgAl2O4; (D) CuO/20%K2CO3/MgAl2O4.

| Catalyst | Cu/K molar ratiob | |||

|---|---|---|---|---|

| MgAl2O4 | 147.1 | 0.5 | 9.3 | |

| CuO/0K2CO3/MgAl2O4 | 125.6 | 0.5 | 9.6 | |

| CuO/5%K2CO3/MgAl2O4 | 110.3 | 0.4 | 9.5 | 0.35 |

| CuO/10%K2CO3/MgAl2O4 | 77.4 | 0.3 | 9.3 | 0.29 |

| CuO/20%K2CO3/MgAl2O4 | 49.4 | 0.2 | 9.1 | 0.19 |

Table 2 BET specific surface area(SBET), pore volume(Vp), pore diameter(dp) and Cu/K molar ratio of the fresh catalysts

| Catalyst | Cu/K molar ratiob | |||

|---|---|---|---|---|

| MgAl2O4 | 147.1 | 0.5 | 9.3 | |

| CuO/0K2CO3/MgAl2O4 | 125.6 | 0.5 | 9.6 | |

| CuO/5%K2CO3/MgAl2O4 | 110.3 | 0.4 | 9.5 | 0.35 |

| CuO/10%K2CO3/MgAl2O4 | 77.4 | 0.3 | 9.3 | 0.29 |

| CuO/20%K2CO3/MgAl2O4 | 49.4 | 0.2 | 9.1 | 0.19 |

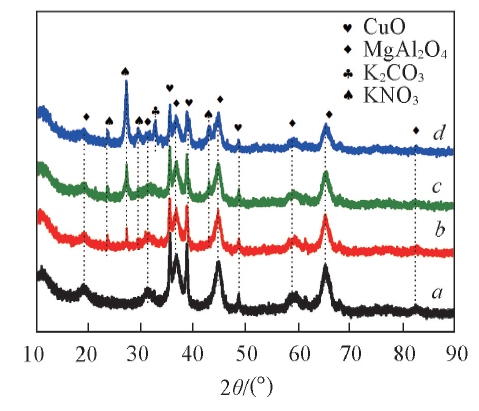

Fig.4 XRD patterns of the catalysts after NOx storage reactiona. CuO/0K2CO3/MgAl2O4; b. CuO/5%K2CO3/MgAl2O4; c. CuO/10%K2CO3/MgAl2O4; d. CuO/20%K2CO3/MgAl2O4.

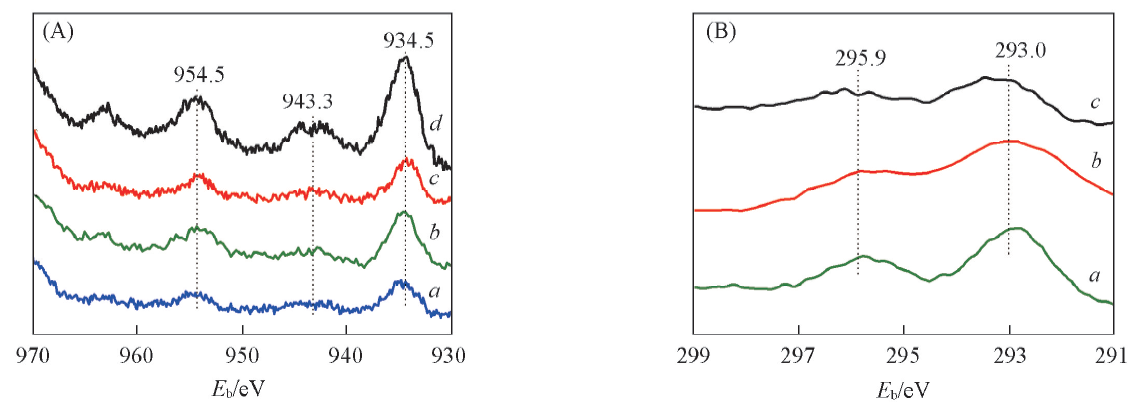

Fig.5 XPS spectra of Cu2p(A) and K2p(B) of the fresh catalystsa. CuO/0K2CO3/MgAl2O4; b. CuO/5%K2CO3/MgAl2O4; c. CuO/10%K2CO3/MgAl2O4; d. CuO/20%K2CO3/MgAl2O4.

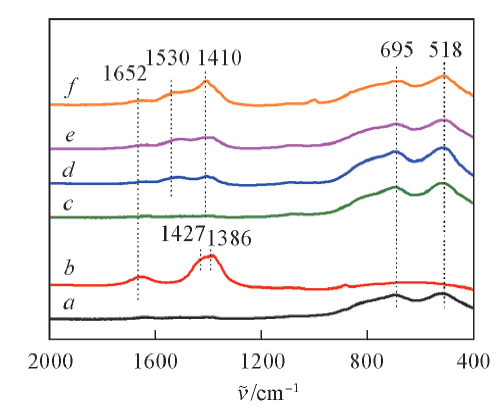

Fig.7 FTIR spectra of the samplesa. MgAl2O4; b. K2CO3; c. CuO/0K2CO3/MgAl2O4;d. CuO/5%K2CO3/MgAl2O4; e. CuO/10%K2CO3/MgAl2O4; f. CuO/20%K2CO3/MgAl2O4.

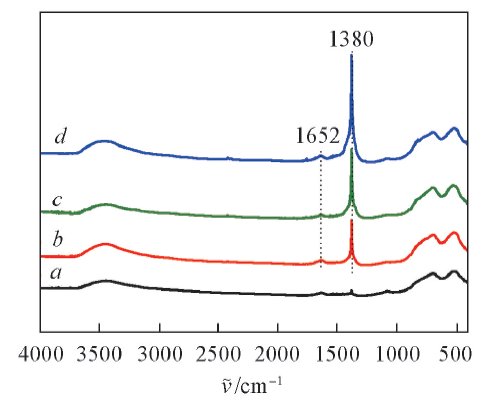

Fig.8 FTIR spectra of the catalysts after NOx storage reactiona. CuO/0K2CO3/MgAl2O4; b. CuO/5%K2CO3/MgAl2O4; c. CuO/10%K2CO3/MgAl2O4; d. CuO/20%K2CO3/MgAl2O4.

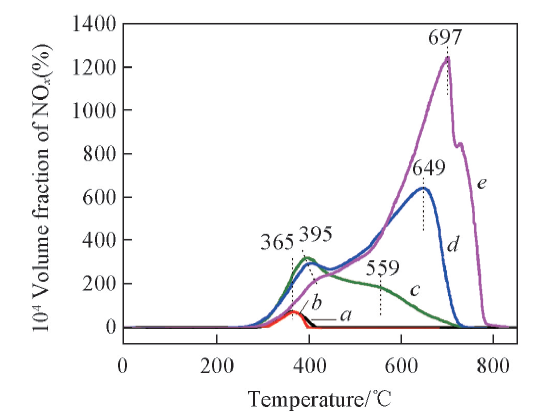

Fig.10 NOx-TPD profiles of the catalysts with different K loadings after NOx storagea. MgAl2O4; b. CuO/0K2CO3/MgAl2O4; c. CuO/5%K2CO3/MgAl2O4; d. CuO/10%K2CO3/MgAl2O4; e. CuO/20%K2CO3/MgAl2O4.

| [1] | Kaspar J., Fornasiero P., Hickey N., Chem. J. Chinese Universities,2010, 31(4), 419-449 |

| [2] | Kreuzer T., Lox E. S., Lindner D., Leyrer J., Chem. J. Chinese Universities,2010, 31(1-4), 17-27 |

| [3] | Alkemade U. G., Schumann B., Chem. J. Chinese Universities,2010, 31(26), 2291-2296 |

| [4] | Roy S., Baiker A., Chem. Rev., 2009, 109(9), 4054-4091 |

| [5] | Koebel M., Elsener M., Kleemann M., Chem. J. Chinese Universities,2010, 31(3/4), 335-345 |

| [6] | Gabrielsson P. L. T., Top. Catal., 2004, 28(1), 177-184 |

| [7] | Sun X. L., He H., Su G. C., Yan J. F., Song L. Y., Qiu W. G., Chem. J. Chinese Universities,2010, 31(5), 814-822 |

| (孙向丽, 何洪, 苏垚超, 闫京芳, 宋丽云, 邱文革. 高等学校化学学报, 2017, 38(5), 814-822) | |

| [8] | Shinjoh H., Takahashi N., Yokota K., Sugiura M., Appl. Catal. B-Environ., 1998, 15(3/4), 189-201 |

| [9] | Sedlmair C., Seshan K., Jentys A., Lercher J., J. Catal., 2003, 214(2), 308-316 |

| [10] | Takahashi N., Shinjoh H., Iijima T., Suzuki T., Yamazaki K., Yokota K., Suzuki H., Miyoshi N., Matsumoto S., Tanizawa T., Chem. J. Chinese Universities,2010, 31(1/2), 63-69 |

| [11] | Takeuchi M., Matsumoto S. I., Top. Catal., 2004, 28(1), 151-156 |

| [12] | Lietti L., Forzatti P., Nova I., Tronconi E., J. Catal., 2001, 204(17), 175-191 |

| [13] | Kwak J. H., Kim D. H., Szanyi J., Cho S. J., Peden C. H. F., Top. Catal., 2012, 55(1), 70-77 |

| [14] | Hatanaka M., Takahashi N., Tanabe T., Nagai Y., Suda A., Shinjoh H., J. Catal., 2009, 266(2), 182-190 |

| [15] | Tanabe T., Nagai Y., Dohmae K., Sobukawa H., Shinjoh H., J. Catal., 2008, 257(1), 117-124 |

| [16] | Luo J. Y., Gao F., Kim D. H., Peden C. H. F., Chem. J. Chinese Universities,2010, 31(4), 164-172 |

| [17] | Zhang Y. X., Meng M., Dai F. F., Ding T., You R., Chem. J. Chinese Universities,2010, 31(45), 23691-23700 |

| [18] | Takahashi N., Matsunaga S. I., Tanaka T., Sobukawa H., Shinjoh H., Appl. Catal. B-Environ., 2007, 77(1/2), 73-78 |

| [19] | Luo J. Y., Gao F., Karim A. M., Xu P. H., Browning N. D., Peden C. H., ACS Catal., 2015, 5(8), 4680-4689 |

| [20] | You R., Zhang Y. X., Liu D. S., Meng M., Zheng L. R., Zhang J., Hu T. D., Chem. J. Chinese Universities,2010, 31(44), 25403-25420 |

| [21] | Li X. G., Dong Y. H., Xian H., Hernández W. Y., Meng M., Zo H. H., Ma A. J., Zhang T. Y., Jiang Z., Tsubaki N., Energy Environ. Sci., 2011, 4(9), 3351-3354 |

| [22] | Lin T., Xu H. D., Li W., Zhang Q. L., Gong M. C., Chen Y. Q., Chem. J. Chinese Universities,2010, 31(11), 2240-2246 |

| (林涛, 徐海迪, 李伟, 张秋林, 龚茂初, 陈耀强. 高等学校化学学报, 2009, 30(11), 2240-2246) | |

| [23] | Liu J. D., Huang Z. G., Li Z., Guo Q. Q., Li Q. Y., Chem. J. Chinese Universities,2010, 31(3), 589-595 |

| (刘建东, 黄张根, 李哲, 郭倩倩, 李巧艳. 高等学校化学学报, 2014, 35(3), 589-595) | |

| [24] | Zhang Y. X., You R., Liu D. S., Liu C., Li X. G., Tian Y., Zheng J., Zhang S., Huang Y. Y., Zha Y. Q., Appl. Surf. Sci., 2015, 357, 2260-2276 |

| [25] | Fan F. Q., Meng M., Tian Y., Zheng L. R., Zhang J., Hu T. D., Acta Phys. Chim. Sin., 2015, 31(9), 1761-1770 |

| (范丰奇, 孟明, 田野, 郑黎荣, 张静, 胡天斗. 物理化学学报, 2015, 31(9), 1761-1770) | |

| [26] | Wang Q., Chung J. S., Appl. Catal. A-Gen., 2009, 358(1), 59-64 |

| [27] | Ma A. J., Wang S. Z., Liu C., Xian H., Ding Q., Li X. G., Meng M., Tan Y. S., Tsubaki N., Zhang J., Appl. Catal. B-Environ., 2014, 146(5), 24-34 |

| [28] | Avgouropoulos G., Ioannide T., Appl. Catal. A-Gen., 2003, 244(1), 155-167 |

| [29] | Li R., Yu L. M., Yan X. F., Jiang T., Chem. J. Chinese Universities,2010, 31(2), 267-274 |

| (李如, 于良民, 闫雪峰, 江涛. 高等学校化学学报, 2017, 38(2), 267-274) | |

| [30] | Liu N., Wang J. Q., Chen B. H., Li. Y. X., Zhang. R. D., Chem. J. Chinese Universities,2010, 31(10), 1817-1825 |

| (刘宁, 王继琼, 陈标华, 李英霞, 张润铎.高等学校化学学报, 2016, 37(10), 1817-1825) | |

| [31] | Li X., Li Y. J., Li M., Tang N. M., Li. Z. Q., Han Z. Y., Chem. J. Chinese Universities,2010, 31(12), 2246-2252 |

| (林晓, 李佑稷, 李铭, 唐宁梅, 李紫琴, 韩志英. 高等学校化学学报, 2016, 37(12), 2246-2252) | |

| [32] | Zhang G. Q., Zheng H. Y., He Z. Q., Li Y. Z., Chem. J. Chinese Universities,2010, 31(7), 1380-1389 |

| (张国强, 郑华艳, 郝志强, 李摇忠. 高等学校化学学报, 2016, 37(7), 1380-1389) | |

| [33] | Iranmahboob J., Hill. D., Toghiani H., Appl. Surf. Sci., 2001, 185, 72-78 |

| [34] | Toops T. J., Smith D. B., Partridge W. P., Appl. Catal. B-Environ., 2005, 58(3/4), 245-254 |

| [1] | QIU Xinsheng, WU Qin, SHI Daxin, ZHANG Yaoyuan, CHEN Kangcheng, LI Hansheng. Preparation and High Temperature Fuel Cell Performance of Ionic Crosslinked Sulfonated Polyimides for Proton Exchange Membranes [J]. Chem. J. Chinese Universities, 2022, 43(8): 20220140. |

| [2] | ZHANG Jie, YIN Bo, LIU Weixin, LIU Xingping, LIAN Wenxian, TANG Shaokun. Fabrication of Boehmite Fiber-reinforced Silica Aerogels and Their Performances [J]. Chem. J. Chinese Universities, 2022, 43(11): 20220483. |

| [3] | JIAO Long, DAI Xuemin, MU Jianxin, DU Zhijun, WANG Hanfu, DONG Zhixin, QIU Xuepeng. Preparation and Properties of High Heat-resistant Polyimide Films for Flexible OLED [J]. Chem. J. Chinese Universities, 2022, 43(11): 20220390. |

| [4] | CHANG Sihui, CHEN Tao, ZHAO Liming, QIU Yongjun. Thermal Degradation Mechanism of Bio-based Polybutylactam Plasticized by Ionic Liquids [J]. Chem. J. Chinese Universities, 2022, 43(11): 20220353. |

| [5] | QIAO Zhenghua, FAN Qi, HAO Jingcheng. Silicone Surfactant-enhanced Dual Networks and High Temperature Resistance Porous Silicone Elastomers [J]. Chem. J. Chinese Universities, 2022, 43(10): 20220384. |

| [6] | ZHANG Jun, WANG Bin, PAN Li, MA Zhe, LI Yuesheng. Synthesis and Properties of Imidazolium-based Polyethylene Ionomer [J]. Chem. J. Chinese Universities, 2020, 41(9): 2070. |

| [7] | HE Xiaoke, LI Xiaoyun, WANG Zhao, HU Nian, DENG Zhao, CHEN Lihua, SU Baolian. Self-reduction for the Synthesis of Co Supported on Hierarchically Porous Carbon for Selective Hydrogenation Reaction † [J]. Chem. J. Chinese Universities, 2020, 41(4): 639. |

| [8] | RAN Shiya,SHEN Haifeng,LI Xiaonan,WANG Zilu,GUO Zhenghong,FANG Zhengping. Effect and Mechanism of Rare Earth Trifluoromethanesulfonate on the Thermal Stability of Polypropylene† [J]. Chem. J. Chinese Universities, 2019, 40(6): 1333. |

| [9] | FANG Xijie,LIU Ruiyun,LIN Sen,SHI Lei,WANG Runwei,LI Yi,LI Junying. Synthesis of STW-zeotype Germanosilicate via Steam-assisted Crystallization† [J]. Chem. J. Chinese Universities, 2019, 40(5): 867. |

| [10] | REN Xiaorui,LIU Chao,LI Huanhuan,YANG Jingshuai,HE Ronghuan. Siloxane Crosslinked Imidazolium PPO/PTFE Membranes for High Temperature Proton Exchange Membranes† [J]. Chem. J. Chinese Universities, 2019, 40(5): 1089. |

| [11] | LIU Tao,LI Wenjing,ZHANG Enshuang,ZHONG Jinyang,ZHANG Fan,LIU Yuanyuan,ZHAO Yingmin. Preparation and Properties of Flexible Cross-linked Polyimide Aerogels [J]. Chem. J. Chinese Universities, 2019, 40(2): 403. |

| [12] | YIN Mengxin,LIU Dongsheng,ZHAO Dongyue,DING Tong,TIAN Ye,LI Xingang. Effect of Copper Doping on Lean NOx Trap Performance of Pt/Ba/CuxMg1-xAl2O4 Catalysts at High Temperatures † [J]. Chem. J. Chinese Universities, 2019, 40(10): 2170. |

| [13] | XU Yandong,YOU Jinglin,WANG Jian,GONG Xiaoye,DING Yani,CAO Peiming,ZHENG Shaobo,WU Yongquan,YU Zhongda. High-temperature in situ Raman Spectroscopic Study on the Micro-structure of Bi4B2O9 Crystal and Melt † [J]. Chem. J. Chinese Universities, 2019, 40(10): 2143. |

| [14] | LIU Yi, XU Xiaozhou, MO Song, ZHAI Lei, HE Minhui, FAN Lin. Thermal Stability of Polyimide Resins Containing Siloxane Structure and Their High Temperature Structural Evolution [J]. Chem. J. Chinese Universities, 2019, 40(1): 187. |

| [15] | MENG Jiafeng, NI Xufeng, ZHENG Hao, SHEN Zhiquan. Copolymerization of Norbornene and 1-Octene Catalyzed by Bis(phenoxy-imine) Titanium Complex† [J]. Chem. J. Chinese Universities, 2018, 39(8): 1853. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||