Chem. J. Chinese Universities ›› 2019, Vol. 40 ›› Issue (7): 1571.doi: 10.7503/cjcu20190016

• Polymer Chemistry • Previous Articles

ZHANG Xinping, ZHANG Jianping, CAI Lei, ZONG Xin, HE Aihua*( )

)

Received:2019-01-07

Online:2019-07-10

Published:2019-07-12

Contact:

HE Aihua

E-mail:aihuahe@iccas.ac.cn

Supported by:CLC Number:

TrendMD:

ZHANG Xinping, ZHANG Jianping, CAI Lei, ZONG Xin, HE Aihua. Structure and Properties of Damping Materials with Super Fatigue Resistance Based on Chloroprene Rubber†[J]. Chem. J. Chinese Universities, 2019, 40(7): 1571.

| System m(CR):m(TBIR) | Unfilled gum | Filled compound | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 100:0 | 90:10 | 80:20 | 70:30 | 100:0 | 90:10 | 80:20 | 70:30 | ||

| ML/(dN·m) | 0.85 | 0.96 | 1.06 | 1.26 | 2.97 | 2.96 | 3.13 | 3.59 | |

| MH/(dN·m) | 11.41 | 9.50 | 8.38 | 7.76 | 28.55 | 23.62 | 21.54 | 20.85 | |

| MH-ML/(dN·m) | 10.56 | 8.54 | 7.32 | 6.50 | 25.58 | 20.66 | 18.41 | 17.26 | |

| t10/min | 1.87 | 1.76 | 1.79 | 1.71 | 1.48 | 1.36 | 1.31 | 1.32 | |

| t90/min | 19.93 | 18.66 | 17.65 | 17.47 | 19.00 | 16.74 | 15.58 | 14.15 | |

| vr/min-1 | 5.54 | 5.92 | 6.30 | 6.34 | 5.71 | 6.50 | 7.01 | 7.79 | |

Table 1 Curing characteristics of unfilled CR/TBIR gums and filled CR/TBIR compounds

| System m(CR):m(TBIR) | Unfilled gum | Filled compound | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 100:0 | 90:10 | 80:20 | 70:30 | 100:0 | 90:10 | 80:20 | 70:30 | ||

| ML/(dN·m) | 0.85 | 0.96 | 1.06 | 1.26 | 2.97 | 2.96 | 3.13 | 3.59 | |

| MH/(dN·m) | 11.41 | 9.50 | 8.38 | 7.76 | 28.55 | 23.62 | 21.54 | 20.85 | |

| MH-ML/(dN·m) | 10.56 | 8.54 | 7.32 | 6.50 | 25.58 | 20.66 | 18.41 | 17.26 | |

| t10/min | 1.87 | 1.76 | 1.79 | 1.71 | 1.48 | 1.36 | 1.31 | 1.32 | |

| t90/min | 19.93 | 18.66 | 17.65 | 17.47 | 19.00 | 16.74 | 15.58 | 14.15 | |

| vr/min-1 | 5.54 | 5.92 | 6.30 | 6.34 | 5.71 | 6.50 | 7.01 | 7.79 | |

| m(CR):m(TBIR) | Aggregate size/μm | Dispersion degree(%) |

|---|---|---|

| 100:0 | 12.70 | 75.36 |

| 90:10 | 12.60 | 77.37 |

| 80:20 | 12.44 | 77.61 |

| 70:30 | 12.43 | 77.46 |

Table 2 Filler dispersion and mean aggregate size in filled CR/TBIR vulcanizates

| m(CR):m(TBIR) | Aggregate size/μm | Dispersion degree(%) |

|---|---|---|

| 100:0 | 12.70 | 75.36 |

| 90:10 | 12.60 | 77.37 |

| 80:20 | 12.44 | 77.61 |

| 70:30 | 12.43 | 77.46 |

| System m(CR):m(TBIR) | Unfilled CR/TBIR vulcanizates | Filled CR/TBIR vulcanizates | ||||||

|---|---|---|---|---|---|---|---|---|

| 100:0 | 90:10 | 80:20 | 70:30 | 100:0 | 90:10 | 80:20 | 70:30 | |

| Tensile strength/MPa | 10.5 | 12.9 | 13.0 | 13.8 | 19.6 | 19.8 | 20.2 | 20.4 |

| Modulus at 100%/MPa | 1.09 | 1.07 | 1.08 | 1.06 | 4.45 | 4.04 | 4.02 | 3.62 |

| Modulus at 300%/MPa | 1.68 | 1.64 | 1.65 | 1.67 | — | — | 20.02 | 16.71 |

| Elongation at break(%) | 675 | 711 | 726 | 782 | 277 | 283 | 310 | 353 |

| Tear strength/(kN·m-1) | 46.6 | 50.8 | 52.2 | 51.8 | 114.3 | 111.0 | 117.3 | 115.6 |

| Shore A hardness/(°) | 53 | 53 | 57 | 59 | 73 | 74 | 76 | 77 |

| Rebound(%) | 59 | 57 | 56 | 54 | 44 | 41 | 38 | 37 |

| Compression set(%) | 15.2 | 14.4 | 14.3 | 13.5 | 17.6 | 17.2 | 16.4 | 16.0 |

| Heat built-up/℃ | — | — | 24.1 | 21.7 | 43.8 | 41.8 | 40.2 | 38.7 |

| Aging under air at 100 ℃ for 72 h | ||||||||

| Tensile strength/MPa | 5.4 | 6.0 | 6.5 | 7.3 | 19.2 | 17.8 | 16.8 | 15.4 |

| Modulus at 100%/MPa | 1.31 | 1.12 | 0.98 | 0.92 | 6.26 | 4.98 | 4.32 | 4.03 |

| Modulus at 300%/MPa | 2.31 | 1.95 | 1.76 | 1.73 | — | — | — | — |

| Elongation at break(%) | 534 | 554 | 580 | 610 | 212 | 239 | 262 | 270 |

| Aging coefficient(%) | 40.7 | 36.2 | 39.9 | 40.2 | 75.0 | 73.2 | 70.2 | 56.2 |

Table 3 Mechanical properties of unfilled and filled CR/TBIR vulcanizates

| System m(CR):m(TBIR) | Unfilled CR/TBIR vulcanizates | Filled CR/TBIR vulcanizates | ||||||

|---|---|---|---|---|---|---|---|---|

| 100:0 | 90:10 | 80:20 | 70:30 | 100:0 | 90:10 | 80:20 | 70:30 | |

| Tensile strength/MPa | 10.5 | 12.9 | 13.0 | 13.8 | 19.6 | 19.8 | 20.2 | 20.4 |

| Modulus at 100%/MPa | 1.09 | 1.07 | 1.08 | 1.06 | 4.45 | 4.04 | 4.02 | 3.62 |

| Modulus at 300%/MPa | 1.68 | 1.64 | 1.65 | 1.67 | — | — | 20.02 | 16.71 |

| Elongation at break(%) | 675 | 711 | 726 | 782 | 277 | 283 | 310 | 353 |

| Tear strength/(kN·m-1) | 46.6 | 50.8 | 52.2 | 51.8 | 114.3 | 111.0 | 117.3 | 115.6 |

| Shore A hardness/(°) | 53 | 53 | 57 | 59 | 73 | 74 | 76 | 77 |

| Rebound(%) | 59 | 57 | 56 | 54 | 44 | 41 | 38 | 37 |

| Compression set(%) | 15.2 | 14.4 | 14.3 | 13.5 | 17.6 | 17.2 | 16.4 | 16.0 |

| Heat built-up/℃ | — | — | 24.1 | 21.7 | 43.8 | 41.8 | 40.2 | 38.7 |

| Aging under air at 100 ℃ for 72 h | ||||||||

| Tensile strength/MPa | 5.4 | 6.0 | 6.5 | 7.3 | 19.2 | 17.8 | 16.8 | 15.4 |

| Modulus at 100%/MPa | 1.31 | 1.12 | 0.98 | 0.92 | 6.26 | 4.98 | 4.32 | 4.03 |

| Modulus at 300%/MPa | 2.31 | 1.95 | 1.76 | 1.73 | — | — | — | — |

| Elongation at break(%) | 534 | 554 | 580 | 610 | 212 | 239 | 262 | 270 |

| Aging coefficient(%) | 40.7 | 36.2 | 39.9 | 40.2 | 75.0 | 73.2 | 70.2 | 56.2 |

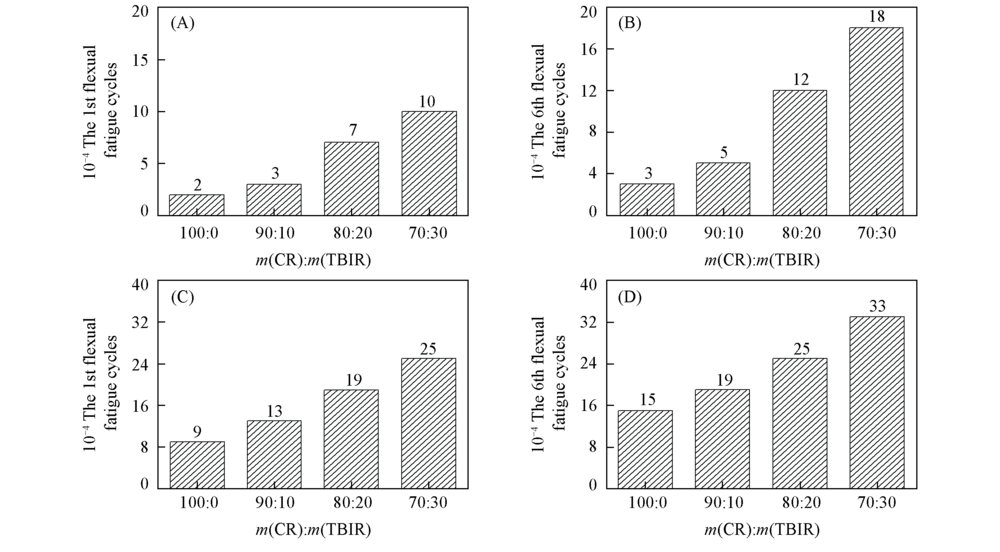

Fig.5 Flexual fatigue resistance performances of unfilled(A, B) and filled CR/TBIR vulcanizates(C, D)(A, C) The 1st flexural fatigue cycles; (B, D) the 6th flexural fatigue cycles.

| [1] | Chung D. D. L., J. Mater. Sci., 2001, 36(24), 5733—5737 |

| [2] | Ponnamma D., Adv. Polym. Sci., 2014, 264, 1—309 |

| [3] | Du J., Yuan Z. X., Material Matching and Mixing Processing, Chemical Industry Press, Beijing, 2003 |

| (杜军, 袁仲雪. 材料配合与混炼加工, 北京: 化学工业出版社, 2003) | |

| [4] | Gao H., Study on Structure and Properties of Neoprene/cis-Polybutadiene Rubber Blends, Tianjin University, Tianjin, 2010 |

| (高宏. 氯丁橡胶/顺丁橡胶共混物结构及性能研究, 天津: 天津大学, 2006) | |

| [5] | Xu Z. C., Wen S. P., Peng T. K., Liao K.,Liu L., Zhang L. Q., Chinese Rubb. Ind., 2017, 64(4), 202—206 |

| (许宗超, 温世鹏, 彭同恺, 廖坤, 刘力, 张立群. 橡胶工业, 2017, 64(4), 202—206) | |

| [6] | Ismail H., Leong H. C., Polym. Test, 2001, 20(5), 509—516 |

| [7] | Choi S., J. Appl. Polym. Sci., 2010, 83(12), 2609—2616 |

| [8] | Sae-Ouiabbcaa P., Eur. Polym. J., 2007, 43(1), 185—193 |

| [9] | Chen F., Cen L., Lei C., Polym. Composite, 2007, 28(5), 667—673 |

| [10] | He A.H., Yao W., Huang B. C., Jiao S. K., Acta Chim. Sinica, 2001, 59(10), 1793—1797 |

| (贺爱华, 姚薇, 黄宝琛, 焦书科. 化学学报, 2001, 59(10), 1793—1797) | |

| [11] | He A. H., Yao W., Jia Z. F., Huang B. C.,Jiao S. K., Acta Polym. Sin., 2002, 24(1), 19—24 |

| (贺爱华, 姚微, 贾志峰, 黄宝琛, 焦书科. 高分子学报, 2002, 24(1), 19—24 | |

| [12] | He A. H., Yao W., Jia Z. F., Huang B. C.,Jiao S. K., Chin. Synth. Rubb. Ind., 2002, 25(2), 75—79 |

| (贺爱华, 姚薇, 贾志峰, 黄宝琛, 焦书科. 合成橡胶工业, 2002, 25(2), 75—79) | |

| [13] | He A.H., Huang B. C., Jiao S. K., Hu Y. L., J. Appl. Polym. Sci., 2003, 89(7), 1800—1807 |

| [14] | Niu Q.T., Zou C., Liu X. Y., Wang R. G., He A. H., Polymer, 2017, 109, 197—204 |

| [15] | Wang H., Zou C., He A. H., Acta Polym. Sin., 2015, (12), 1387—1395 |

| (王浩, 邹陈, 贺爱华. 高分子学报, 2015, (12), 1387—1395) | |

| [16] | Zhang J. P., Song L. Y., Wang H., Wang R. G., He A. H., Chem. J. Chinese Universities, 2018, 39(6), 1334—1341 |

| (张剑平, 宋丽媛, 王浩, 王日国, 贺爱华. 高等学校化学学报, 2018, 39(6), 1334—1341) | |

| [17] | Wang H., Zhang J. P., Ma Y. S., Wang R. G., He A. H., Chem. J. Chinese Universities, 2017, 38(11), 2095—2101 |

| (王浩, 张剑平, 马韵升, 王日国, 贺爱华. 高等学校化学学报, 2017, 38(11), 2095—2101) | |

| [18] | Ren H. C., Wu Y. F., Liu D. D., Nie H. R., He A. H., Chem. J. Chinese Universities, 2018, 39(5), 1091—1097 |

| (任惠成, 武营飞, 刘丹丹, 聂华荣, 贺爱华. 高等学校化学学报, 2018, 39(5), 1091—1097) | |

| [19] | Standardization Administration of the People’s Republic of China, GB/T 16584-1996, Rubber—Measurement of Vulcanization Characteristics With Rotorless Curemeters, Standards Press of China, Beijing, 1996 |

| (中国国家标准化管理委员会. GB/T 16584-1996, 橡胶用无转子硫化仪测定硫化特性, 北京: 中国标准出版社, 1996) | |

| [20] | Standardization Administration of the People’s Republic of China, GB/T 528-2009, Rubber, Vulcanized or Thermoplastic—Determination of Tensile Stress-train Properties, Standards Press of China, Beijing, 2009 |

| (中国国家标准化管理委员会. GB/T 528-2009, 硫化橡胶或热塑性橡胶拉伸应力应变性能的测定, 北京: 中国标准出版社, 2009) | |

| [21] | Standardization Administration of the People’s Republic of China, GB/T 529-2008, Rubber, Vulcanized or Thermoplastic—Determination of Tear Strength, Standards Press of China, Beijing, 2008 |

| (中国国家标准化管理委员会. GB/T 529-2008, 硫化橡胶或热塑性橡胶撕裂强度的测定, 北京: 中国标准出版社, 2008) | |

| [22] | Standardization Administration of the People’s Republic of China, GB/T1681-2009, Rubber—Determination of Rebound Resilience of Vulcanizates, Standards Press of China, Beijing, 2009 |

| (中国国家标准化管理委员会. GB/T1681-2009, 硫化橡胶回弹性的测定, 北京: 中国标准出版社, 2009) | |

| [23] | Standardization Administration of the People’s Republic of China, GB/T531.2-2009, Rubber, Vulcanized or Thermoplastic—Determination of Indentation Hardness—Part 2: IRHD Pocket Meter Method, Standards Press of China, Beijing, 2009 |

| (中国国家标准化管理委员会. GB/T531.2-2009, 硫化橡胶或热塑性橡胶压入硬度试验方法, 第2部分: 便携式橡胶国际硬度计法, 北京: 中国标准出版社, 2009) | |

| [24] | Standardization Administration of the People’s Republic of China, GB/T 7759.1-2015, Rubber, Vulcanized or Thermoplastic—Determination of Compression Set—Part 1: At Ambient or Elevated Temperatures, Standards Press of China, Beijing, 2015 |

| (中国国家标准化管理委员会. GB/T 7759.1-2015, 硫化橡胶或热塑性橡胶压缩永久变形的测定, 第1部分: 在常温及高温条件下, 北京: 中国标准出版社, 2015) | |

| [25] | Standardization Administration of the People’s Republic of China, GB/T 3512-2001, Rubber, Vulcanized or Thermoplastic—Accelerated Ageing and Heat Resistance Tests—Air-Oven Method, Standards Press of China, Beijing, 2001 |

| (中国国家标准化管理委员会. GB/T 3512-2001硫化橡胶或热塑性橡胶热空气加速老化和耐热试验, 北京: 中国标准出版社, 2001) | |

| [26] | Standardization Administration of the People’s Republic of China, GB/T 13934-2006, Rubber, Vulcanized or Thermoplastic—Determination of Flex Cracking and Crack Growth(De Mattia), Standards Press of China, Beijing, 2006 |

| (中国国家标准化管理委员会. GB/T 13934-2006, 硫化橡胶或热塑性橡胶屈挠龟裂和裂口增长的测定(德墨西亚型), 北京: 中国标准出版社, 2006) | |

| [27] | Bouty A., Petitjean L., Degrandcourt C., Gummel J., Kwas$\acute{S}$niewski P., Meneau F., Boué F., Couty M., Jestin J., Macromolecules, 2014, 47, 5365—5378 |

| [28] | Liu Y.P., Du A. H., Liu F. Y., Yao W., Huang B. C., China Elastomerics, 2006, 16(6), 10—13 |

| (刘玉鹏, 杜爱华, 刘付永, 姚薇, 黄宝琛. 弹性体, 2006, 16(6), 10—13 | |

| [29] | Gubbels F., Jerome R., Chem. Mater., 1998, 10, 1227—1235 |

| [30] | Rublon P., Huneau P.B., Saintier N., Beurrot S., Leygue A., Verron E., Mocuta C., Thiaudiere D., Berghezan D., J. Synchrotron Radiat., 2013, 20, 105—109 |

| [31] | Zhang J.P., Zhang X. P., Cai L., Zong X., He A. H., Chinese Polym. Bull., |

| (张剑平, 张新萍, 蔡磊, 宗鑫, 贺爱华. 高分子通报, | |

| [32] | Zhang X. P., Wang H., Ren H. C., Wang R. G.,He A. H., Ind. Eng. Chem. Res., 2019, 58, 917—925 |

| [33] | Joly S., Garnaud G., Ollitrault R., Bokobza L., Chem. Mater., 2002, 14, 4202—4208 |

| [34] | Morozov I. A., Macromolecules, 2016, 49, 5985—5992 |

| [35] | Zhang X. P., Cui H. H., Song L. Y., Ren H. C.,Wang R. G., He A. H., Compos. Sci. Technol., 2018, 158, 156—163 |

| [36] | Wang H., Zhang X.P., Nie H. R., Wang R. G., He A. H., Compos. Part A, 2019, 116, 197—205 |

| [1] | LONG Shijun,CHEN Mingmin,ZHAO Youjiao,WANG Xiaotao,LI Xuefeng,LIAO Yonggui. Regulation of Gemini Surfactant on Photochromic Behavior of PVA Dispersed Spiropyran Organogel Thin Film† [J]. Chem. J. Chinese Universities, 2018, 39(5): 1078. |

| [2] | MENG Yan, YU Xiao-Qiang, LI Hong-Tu, WANG Jing-Yuan, YANG Song-Ru, TANG Xin-Yi, SUN Jia-Zhong . Studies on Sound Absorption Coefficient on Polymer Damping Materials [J]. Chem. J. Chinese Universities, 2004, 25(2): 391. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||